Products

400mm RP Graphite Electrode-Engineered for Stable Conductivity and Mechanical Integrity in High-Volume EAF Steelmaking

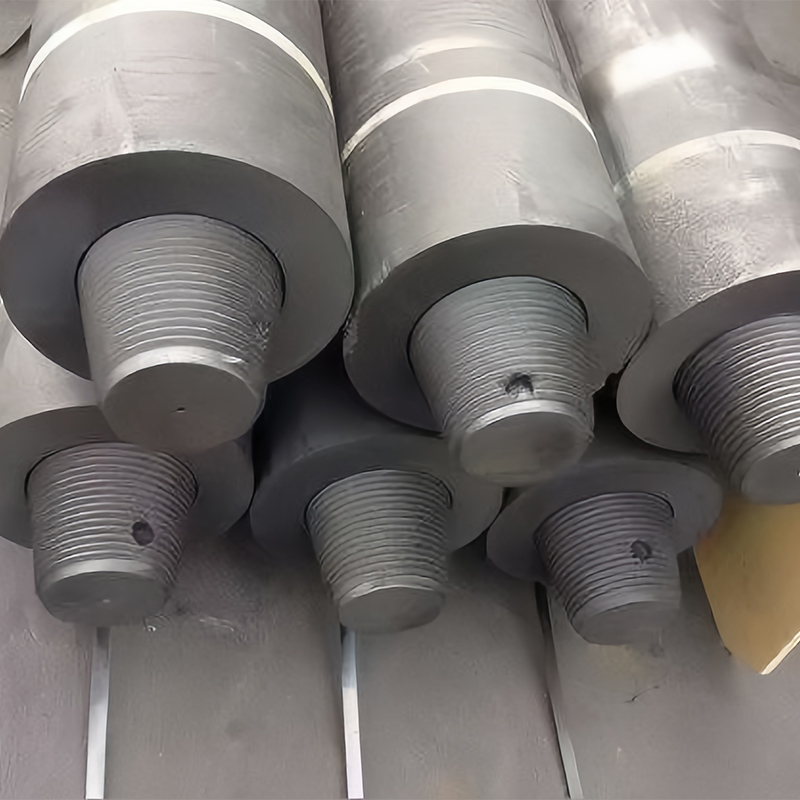

The 400mm RP (Regular Power) graphite electrode is engineered for electric arc furnaces (EAF) operating under standard power conditions. It offers reliable current conductivity, arc stability, and mechanical integrity, making it well-suited for carbon and alloy steel production facilities with annual outputs exceeding 500,000 metric tons.

Description

marker

Basic Description

The 400mm Regular Power (RP) graphite electrode is specifically designed to meet the rigorous demands of large-capacity electric arc furnaces (EAFs), capable of carrying currents ranging from 18,000 to 23,500 A. Tailored for standard power operations, it combines enhanced electrical efficiency with robust structural stability.

RP Graphite Electrodes Parameters — 400mm

| Parameter | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 7.5 ~ 8.5 | 5.8 ~ 6.5 |

| Bending Strength | MPa | ≥ 8.5 | ≥ 16.0 |

| Elastic Modulus | GPa | ≤ 9.3 | ≤ 13.0 |

| Bulk Density | g/cm³ | 1.55 ~ 1.63 | ≥ 1.74 |

| Thermal Expansion Coefficient (CTE) | 10⁻⁶/°C | ≤ 2.4 | ≤ 2.0 |

| Ash Content | % | ≤ 0.3 | ≤ 0.3 |

| Allowable Current | A | — | 18000 ~ 23500 |

| Current Density | A/cm² | — | 14 ~ 18 |

| Actual Diameter | mm | Max: 409 Min: 403 | — |

| Actual Length | mm | 1800 ~2400 (Customizable) | — |

| Length Tolerance | mm | ±100 | — |

| Short Ruler Length | mm | -275 | — |

Material Processing Enhancements

Raw Material

High-purity petroleum needle coke with sulfur content below 0.5% is selected as the raw material. It undergoes high-temperature calcination (up to 1300 °C) to remove volatiles and optimize carbon crystalline structure, enhancing electrical and thermal performance.

Dual Impregnation & Baking

A two-stage pitch impregnation followed by secondary baking reduces open porosity by approximately 15% compared to conventional RP electrodes. This process improves oxidation resistance, arc erosion tolerance, and structural reliability under thermal cycling conditions.

CNC Threading

High-precision CNC machining is used for thread forms (3TPI / 4TPI / M72x4), ensuring tight joint fit and minimal contact resistance.

Application Fields

| Sector | Description |

| Electric Arc Furnace (EAF) | For melting scrap and DRI under medium power input |

| Ladle Furnace (LF) | Maintains molten metal temperature and improves purity during secondary refining |

| Alloy Steel Production | Effective for high-throughput lines producing specialty and construction steels |

Performance Advantages

● High current-carrying capacity for large EAFs

● Low elastic modulus reduces thermal stress

● Superior oxidation and arc erosion resistance

● Typical electrode consumption: ~0.8–1.1 kg/ton of steel

● Extended operational life with fewer replacements

Environmental & Energy Considerations

● Energy Consumption: Approx. 6000 kWh per metric ton of electrode

● Emission Control: Compliant with modern standards via dust/fume collection and gas treatment

● Sustainability: Reduced consumption helps minimize environmental impact

Conclusion

The 400mm RP graphite electrode offers a reliable and cost-effective solution for standard-power EAF operations. Through superior materials, advanced processing, and precision machining, it ensures high conductivity, long service life, and stable furnace performance in demanding steelmaking environments.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic