Products

450mm UHP Graphite Electrode Technical Overview

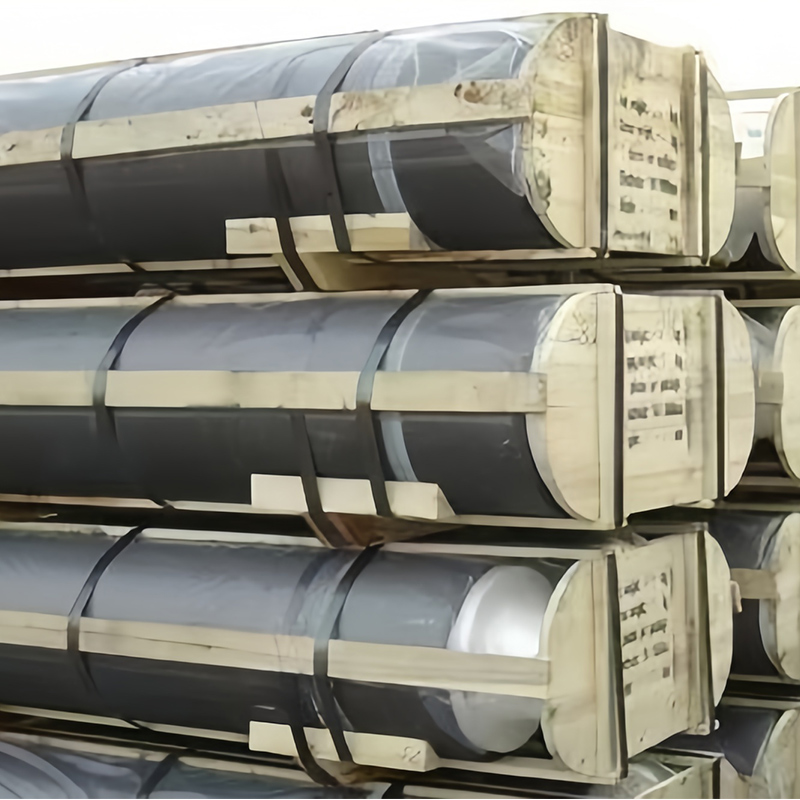

The 450mm Ultra High Power (UHP) graphite electrode is a critical consumable widely used in electric arc furnace (EAF) steelmaking, ladle refining, and non-ferrous metallurgy. It delivers excellent electrical conductivity, thermal shock resistance, and mechanical strength to optimize furnace performance and steel quality.

Description

marker

Basic Description

The 450mm Ultra High Power (UHP) Graphite Electrode is a critical consumable extensively used in electric arc furnace (EAF) steelmaking and other high-temperature metallurgical processes. Manufactured from premium-grade petroleum coke and needle coke, and processed through advanced baking, graphitization, and precision machining, this electrode offers exceptional electrical conductivity, thermal shock resistance, and mechanical strength.

Key Technical Specifications

| Parameter | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 4.5 ~ 5.6 | 3.4 ~ 3.8 |

| Bending Strength | MPa | ≥ 12.0 | ≥ 22.0 |

| Elastic Modulus | GPa | ≤ 13.0 | ≤ 18.0 |

| Bulk Density | g/cm³ | 1.68 ~ 1.72 | 1.78 ~ 1.84 |

| Thermal Expansion Coefficient | 10⁻⁶/°C | ≤ 1.2 | ≤ 1.0 |

| Ash Content | % | ≤ 0.2 | ≤ 0.2 |

| Allowable Current | A | — | 32000 ~ 45000 |

| Current Density | A/cm² | — | 19 ~ 27 |

| Actual Diameter | mm | Max: 460 Min: 454 | — |

| Actual Length (Customizable) | mm | 1800 – 2400 | — |

| Length Tolerance | mm | ±100 | — |

| Short Ruler Length | mm | -275 | — |

Manufacturing Process

● Raw Materials:Low-sulfur petroleum needle coke (<0.03%) to ensure high purity and conductivity.

● Forming:Isostatic pressing for uniform density and structural integrity.

● Baking:Multi-stage baking up to ~900°C to enhance strength and bonding.

● Graphitization:Treatment above 2800°C to produce high-quality graphite with superior conductivity and thermal stability.

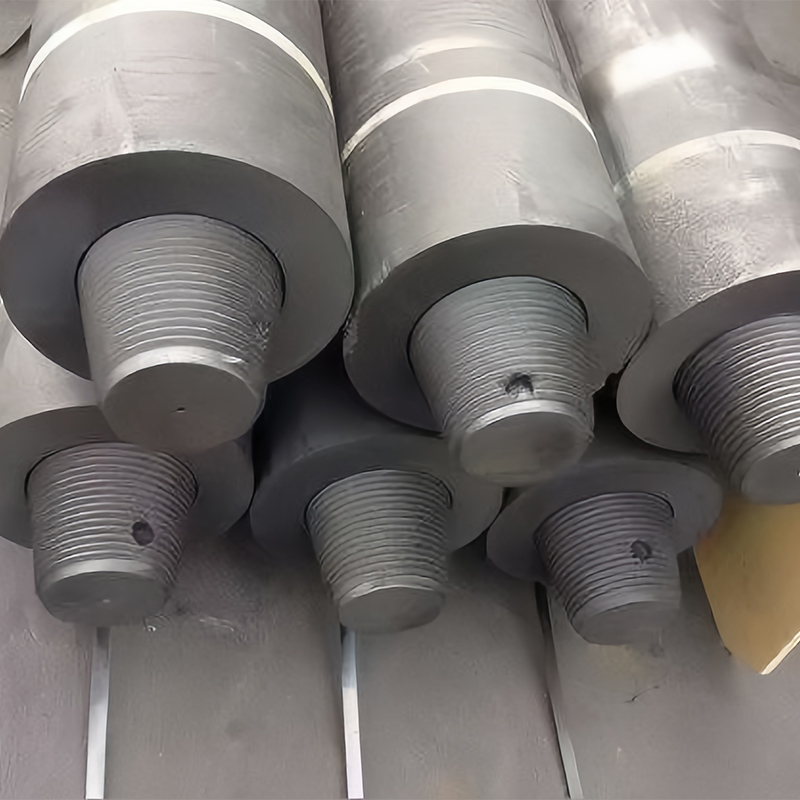

● Machining:Precision CNC machining of threads and dimensions ensures secure, low-resistance connections.

Applications

● Electric Arc Furnace (EAF):Primary electrodes for melting scrap and direct reduced iron (DRI), providing stable arcs and efficient energy transfer.

● Ladle Furnace (LF) and Argon Oxygen Decarburization (AOD) Furnaces:Electrodes for secondary refining and precise temperature control.

● Non-Ferrous Metallurgy:Melting and refining of copper, aluminum, nickel, and specialty alloys requiring high purity.

● Chemical Industry:Used in high-temperature reactors and in the production of silicon, calcium carbide, and other carbon-based chemicals.

Advantages

● High Electrical Conductivity:Minimizes power loss and reduces energy consumption.

● Excellent Thermal Shock Resistance:Prevents cracking, extending electrode service life.

● Robust Mechanical Properties:High bending strength and elastic modulus resist operational stresses.

● Low Impurity Content:Improves metal quality by minimizing contamination.

● Precisely CNC-Machined Nipples:Ensures tight, low-resistance electrical connections and stable arc performance.

Conclusion

The 450mm UHP graphite electrode and its precisely machined nipples conform to the highest standards of electrical, thermal, and mechanical performance. This makes it an indispensable component for efficient and stable operation in modern steelmaking and metallurgical processes.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic