Products

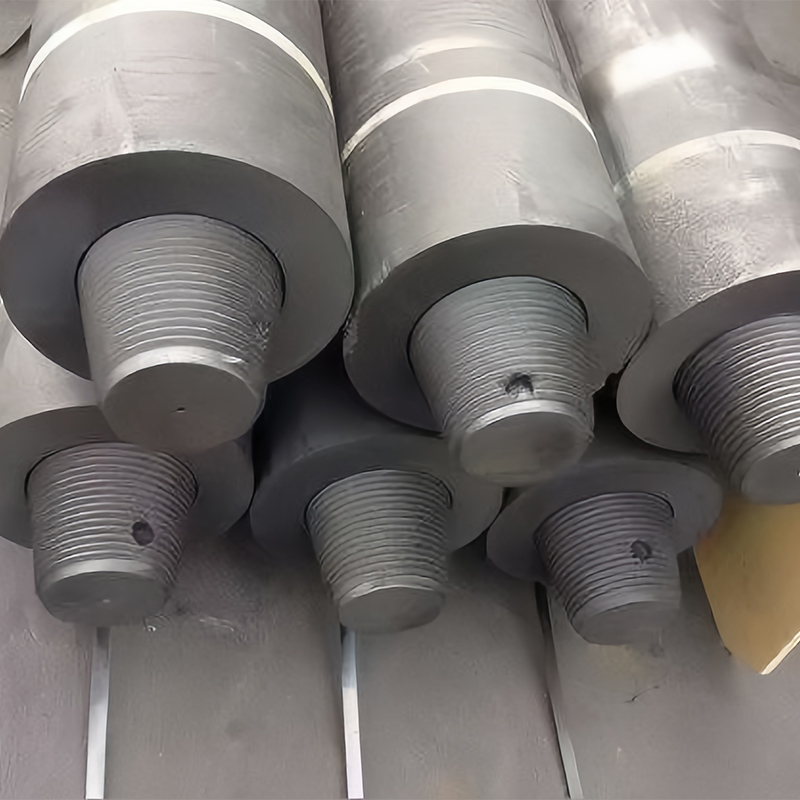

550mm High Power Graphite Electrode (HP) — Custom-Engineered for High-Load Applications

The 550mm high-power graphite electrode is a custom, non-standard product tailored for large-capacity submerged arc furnaces (SAF). It offers exceptional thermal stability, electrical conductivity, and mechanical strength, widely used in extreme smelting conditions such as manganese alloy production.

Description

marker

Product Description

This HP electrode is specially developed for high-load metallurgical operations, mainly for submerged arc furnaces in ferroalloy production under high-temperature, high-current density conditions.

HP Graphite Electrode Parameters — 550mm

| Item | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 5.2 ~ 6.5 | 3.5 ~ 4.5 |

| Bending Strength | MPa | ≥ 11.0 | ≥ 22.0 |

| Elastic Modulus | GPa | ≤ 12.0 | ≤ 15.0 |

| Bulk Density | g/cm³ | 1.68 ~ 1.73 | 1.78 ~ 1.83 |

| Thermal Expansion CTE | 10⁻⁶/℃ | ≤ 2.0 | ≤ 1.8 |

| Ash Content | % | ≤ 0.2 | ≤ 0.2 |

| Allowable Current | A | — | 34000–53000 |

| Current Density | A/cm² | — | 14–22 |

| Actual Diameter | mm | Max 562 Min 556 | — |

| Actual Length | mm | 1800 ~ 2400 customizable | — |

| Length Tolerance | mm | ±100 | — |

| Short Length | mm | — | — |

Raw Materials & Manufacturing

● Formula: 70% petroleum-based needle coke + 30% coal-based coke — balancing conductivity, thermal resistance, and cost.

● Forming: Non-equidistant spiral extrusion ensures directional conductivity and reduced anisotropy effects.

● Processing: Multiple vacuum impregnations + high-temperature baking + graphitization over 85 days in furnaces ≥1.8 m diameter ensure crystalline orientation and low resistivity.

Storage & Handling

● Avoid humidity fluctuations to prevent micro-cracking and oxidation.

● Recommended storage temperature: 25℃ ± 5℃

● Packaging: Reinforced anti-collision wooden crates with moisture-proof lining.

● Lifting: Only use non-metallic slings. No direct metal chain contact.

Applications & Export Markets

● Widely used in Southeast Asia and the Middle East

● Ideal for:

1.FeMn, SiMnsubmerged arc furnace operations

2.≥300-ton EAFs and ≥45 MVA SAFs

Key Performance Advantages

● Excellent thermal shock and oxidation resistance

● Lower consumption per ton (≈0.5 kg/ton reduction)

● Enhanced arc stability and joint conductivity

● Longer service life, even under extreme loads

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic