Products

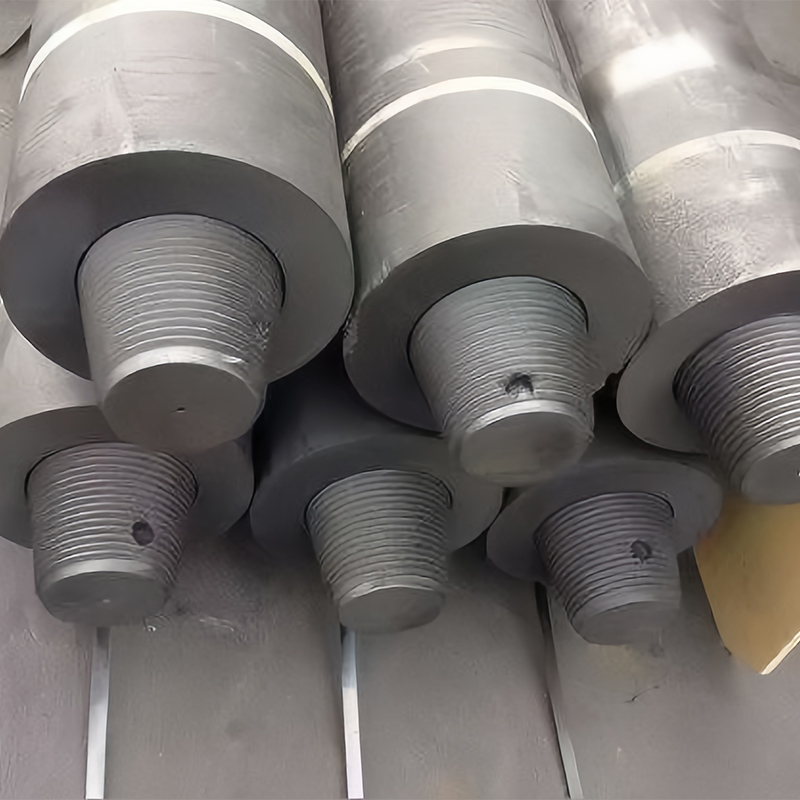

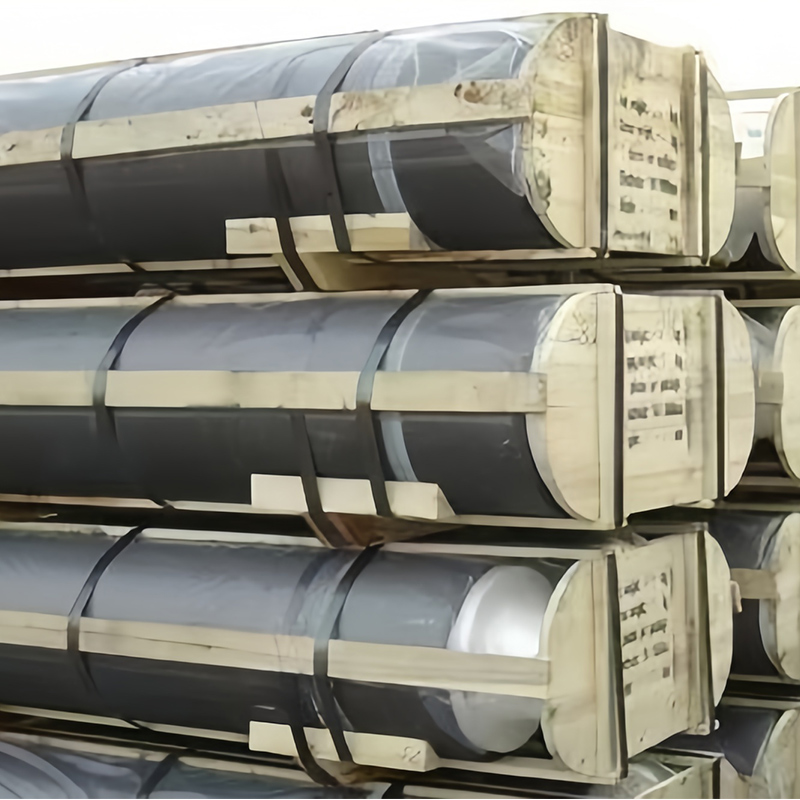

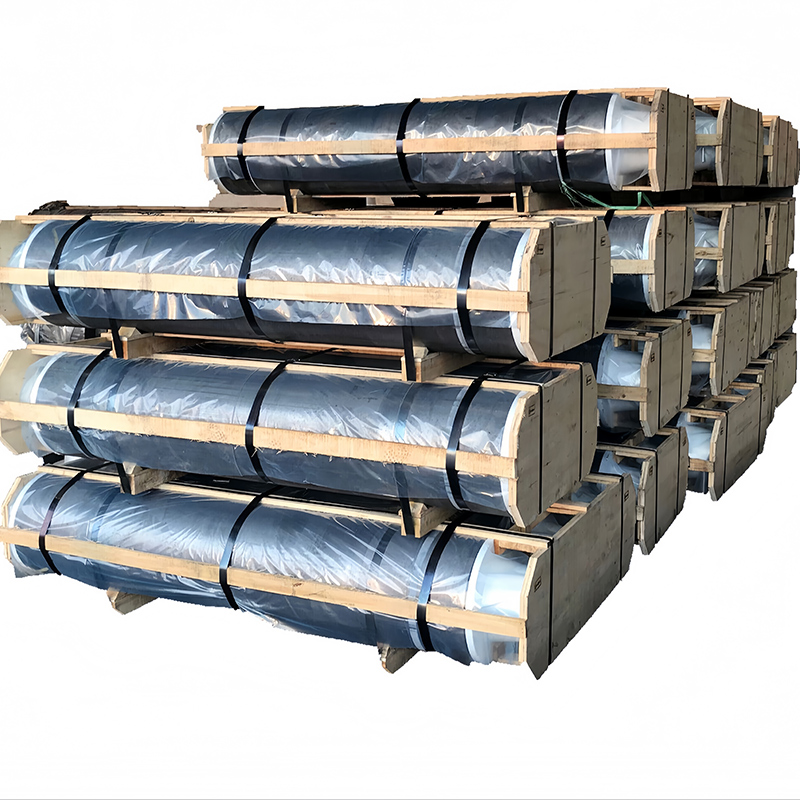

550mm UHP Graphite Electrode

The 550mm UHP graphite electrode, known for its excellent conductivity and thermal stability, is widely applied in electric arc furnaces (EAF) and ladle furnaces (LF). It supports efficient, stable melting and refining of steel and non-ferrous metals, significantly improving melting speed and energy efficiency while ensuring metal purity and product quality. It is a core consumable in modern metallurgical production, meeting the stringent demands of large-scale steel and non-ferrous metal plants.

Description

marker

Basic Description

The 550mm Ultra High Power (UHP) Graphite Electrode is a high-performance consumable extensively utilized in electric arc furnace (EAF) steelmaking and various high-temperature metallurgical operations. Manufactured from premium petroleum coke and needle coke using advanced baking, graphitization, and precision machining processes, this electrode exhibits exceptional electrical conductivity, outstanding thermal shock resistance, and superior mechanical strength, making it indispensable for modern steel production facilities.

Key Technical Specifications:

| Parameter | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 4.5 ~ 5.6 | 3.4 ~ 3.8 |

| Bending Strength | MPa | ≥ 12.0 | ≥ 22.0 |

| Elastic Modulus | GPa | ≤ 13.0 | ≤ 18.0 |

| Bulk Density | g/cm³ | 1.68 ~ 1.72 | 1.78 ~ 1.84 |

| Thermal Expansion Coefficient | 10⁻⁶/°C | ≤ 1.2 | ≤ 1.0 |

| Ash Content | % | ≤ 0.2 | ≤ 0.2 |

| Allowable Current | A | — | 45000 ~ 65000 |

| Current Density | A/cm² | — | 18 ~ 27 |

| Actual Diameter | mm | Max: 562 Min: 556 | — |

| Actual Length (Customizable) | mm | 1800 - 2400 | — |

| Length Tolerance | mm | ±100 | — |

| Short Ruler Length | mm | -275 | — |

Application Scenarios:

● In steelmaking, the 550mm UHP graphite electrode serves as the main conductor of electric current, generating intense arcs to efficiently melt scrap steel, minimizing power loss and ensuring stable furnace operation.

● It is also crucial in ladle furnace (LF) and argon oxygen decarburization (AOD) processes, where it enhances secondary refining, improving steel purity and precise alloy composition control.

● Beyond steel, it finds wide application in non-ferrous metallurgy for melting and refining copper, aluminum, nickel, and other metals requiring high purity and excellent electrical conductivity.

● Additionally, it is employed in the chemical industry within high-temperature reactors for producing silicon, calcium carbide, and other carbon-based chemical products.

Advantages of 550mm UHP Graphite Electrodes:

● Superior electrical conductivity reduces power consumption and enhances energy efficiency.

● Excellent thermal shock resistance prolongs electrode lifespan and minimizes downtime.

● High mechanical strength guarantees stability under heavy electrical loads and mechanical handling.

● Low impurity content ensures higher quality of molten metal by reducing contamination.

Summary

The 550mm UHP graphite electrode exemplifies the pinnacle of efficiency and durability in steelmaking and metallurgical industries. Its superior electrical and mechanical properties ensure efficient energy transfer, long service life, and minimal contamination, making it an essential component in electric arc furnaces and other high-temperature applications. Manufactured to rigorous quality standards with customizable dimensions, it meets the evolving demands of modern steel manufacturers seeking to optimize production efficiency and steel quality. Selecting premium 550mm UHP graphite electrodes directly contributes to operational cost savings and improved furnace productivity.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic