Products

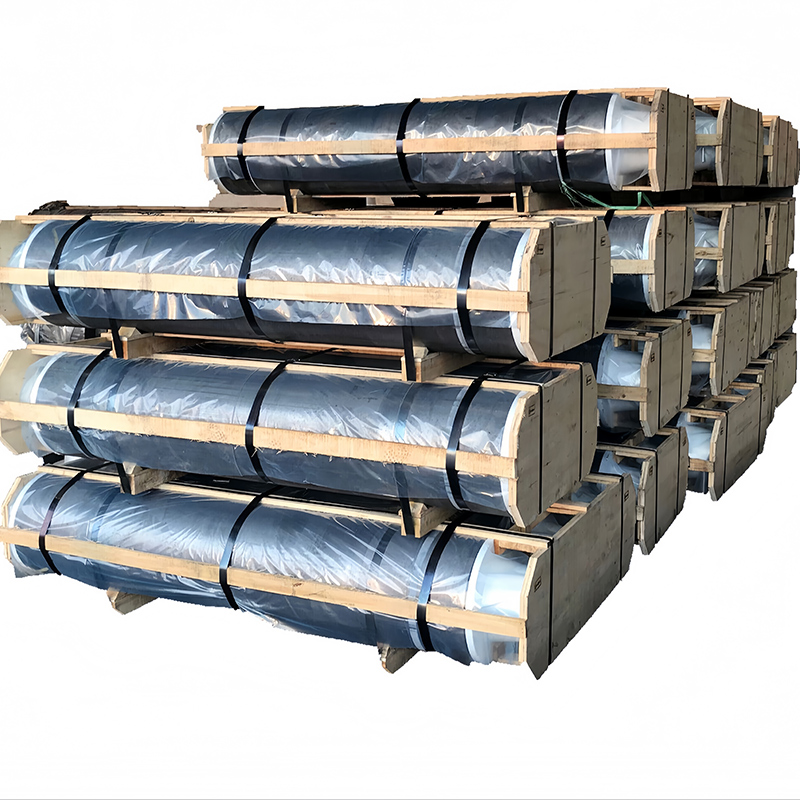

600mm UHP Graphite Electrode

The 600mm UHP graphite electrode is widely used in electric arc furnaces (EAF) and ladle furnaces (LF), suitable for high-temperature and high-load operations. With excellent electrical conductivity, thermal shock resistance, and low consumption, it is ideal for melting scrap, DRI, and non-ferrous metals, making it a preferred choice for advanced metallurgical applications.

Description

marker

Basic Description

The 600mm UHP (Ultra High Power) graphite electrode is a premium-grade consumable extensively used in electric arc furnaces (EAF) and ladle furnaces (LF) for large-scale steelmaking and non-ferrous metal refining. With its exceptional electrical conductivity, thermal resistance, and mechanical strength, this electrode guarantees optimal performance under extreme high-temperature and high-current conditions.

Key Technical Specifications:

| Parameter | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 4.5 ~ 5.4 | 3.0 ~ 3.6 |

| Bending Strength | MPa | ≥ 10.0 | ≥ 24.0 |

| Elastic Modulus | GPa | ≤ 13.0 | ≤ 20.0 |

| Bulk Density | g/cm³ | 1.68 ~ 1.72 | 1.80 ~ 1.86 |

| Thermal Expansion Coefficient | 10⁻⁶/°C | ≤ 1.2 | ≤ 1.0 |

| Ash Content | % | ≤ 0.2 | ≤ 0.2 |

| Allowable Current | A | — | 52000 ~ 78000 |

| Current Density | A/cm² | — | 18 ~ 27 |

| Actual Diameter | mm | 600 | — |

| Actual Length (Customizable) | mm | 2200 - 2700 | — |

| Length Tolerance | mm | ±100 | — |

| Short Ruler Length | mm | -300 | — |

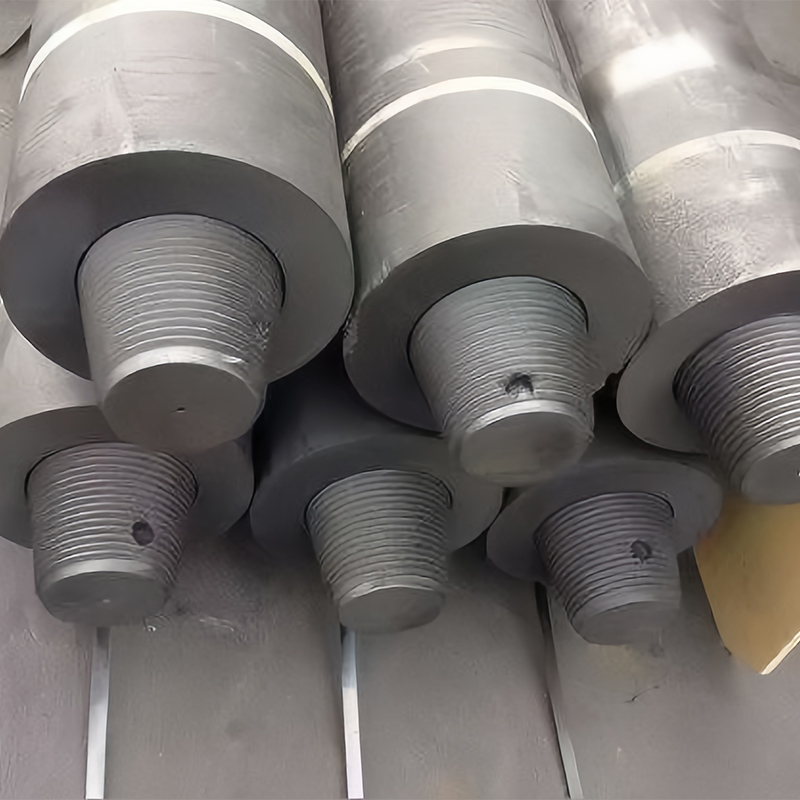

Manufacturing Process:

600mm UHP graphite electrodes are made from high-purity needle coke, processed through calcination, forming, baking, high-pressure impregnation, and graphitization at temperatures over 2800°C. The electrodes and nipple connectors are precision-machined to ensure tight junctions, low contact resistance, and high stability during arc operation.

Application Scenarios:

● Electric Arc Furnace (EAF) Steelmaking

In large steel plants, 600mm UHP electrodes are essential for melting scrap and DRI with ultra-high power input. They ensure faster melting cycles, lower electrode consumption, and higher energy efficiency.

● Ladle Furnace (LF) Secondary Metallurgy

Used for temperature compensation and final alloy adjustments, ensuring clean steel, precise composition, and improved metallurgical control.

● Non-Ferrous Metal Melting

Also used for melting aluminum, copper, and nickel alloys, where stable arc and low impurity levels are vital to end-product quality.

Core Advantages:

● Excellent Conductivity: Ensures efficient energy transfer with minimal losses

● Thermal Shock Resistance: Long lifespan in high-thermal-cycle operations

● High Structural Strength: Reduces risk of breakage during handling and arc loading

● Low Ash & Impurities: Minimizes contamination of molten metal

● Lower Cost per Ton: Longer service life and reduced consumption optimize lifecycle cost

Conclusion:

The 600mm UHP graphite electrode is an indispensable asset for modern steelmaking and advanced metallurgy. Combining state-of-the-art carbon materials, precision engineering, and industry-proven durability, it enhances furnace performance while reducing operational costs. Ideal for manufacturers focused on efficiency, consistency, and high-quality output, this electrode delivers exceptional value in demanding industrial environments.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic