Products

Calcined Petroleum Coke (CPC)

Calcined Petroleum Coke (CPC) is essential for producing graphite electrodes in electric arc furnaces, aluminum smelting anodes, recarburizers in iron casting, and as a reducing agent in TiO₂ chloride processes—making it a key raw material in high-temperature metallurgy and carbon-intensive applications.

Description

marker

Basic Description

High-Purity Carbon Material for Graphite Electrode and Metallurgical Applications

Calcined Petroleum Coke (CPC) is a high-carbon material produced by calcining green petroleum coke at temperatures between 1200°C and 1500°C. This thermal treatment removes moisture, volatile matter, and enhances the fixed carbon content and structural crystallinity. CPC plays a vital role in the graphite electrode industry—particularly in manufacturing RP (Regular Power), HP (High Power), and UHP (Ultra-High Power) electrodes used in Electric Arc Furnaces (EAF) and Ladle Furnaces (LF).

Technical Specifications (Typical Values)

| Property | Specification Range |

| Fixed Carbon (FC) | ≥ 98.5% – 99.5% |

| Sulfur (S) Content | ≤ 0.5% (can be customized to ≤ 0.3%) |

| Volatile Matter (VM) | ≤ 0.5% |

| Ash Content | ≤ 0.5% |

| Moisture | ≤ 0.3% |

| Real Density | 2.03 – 2.10 g/cm³ |

| Apparent Density | 0.96 – 1.10 g/cm³ |

| Particle Size Distribution | 0–1mm, 1–5mm, or tailor-made |

Low-sulfur, high-purity CPC is essential for UHP graphite electrode manufacturing, where strict impurity control is critical.

Key Advantages

● Ultra-High Carbon Purity:Supports low electrode consumption and stable arc performance.

● Excellent Electrical Conductivity:Ensures optimal current transmission during steel melting.

● Low Sulfur and Ash:Minimizes furnace contamination—ideal for high-grade steel production.

● Good Thermal Shock Resistance:Maintains structural integrity under rapid heating and cooling cycles.

● Customizable Particle Sizes:Suitable for baking, pressing, and vibrational molding in electrode production.

Core Applications

● Graphite Electrode Raw Material

CPC is a fundamental component in producing RP/HP/UHP graphite electrodes for steelmaking in EAFs and refining in LFs. For UHP electrodes, low-sulfur, easily graphitizable CPC grades are preferred.

● Recarburizer / Carbon Raiser

CPC is widely used in foundries as a recarburizer to increase carbon content in molten steel and ductile iron. High fixed carbon and low sulfur ensure clean additions.

● Aluminum Smelting Anodes

Low-sulfur CPC is used in anode blocks for aluminum electrolysis via the Hall–Héroult process due to its good thermal conductivity and oxidation resistance.

● Titanium Dioxide & Chemical Industry

As a carbon reductant, CPC is applied in TiO₂ production (chloride process) and other chemical syntheses requiring high-temperature carbon materials.

Why Choose Us?

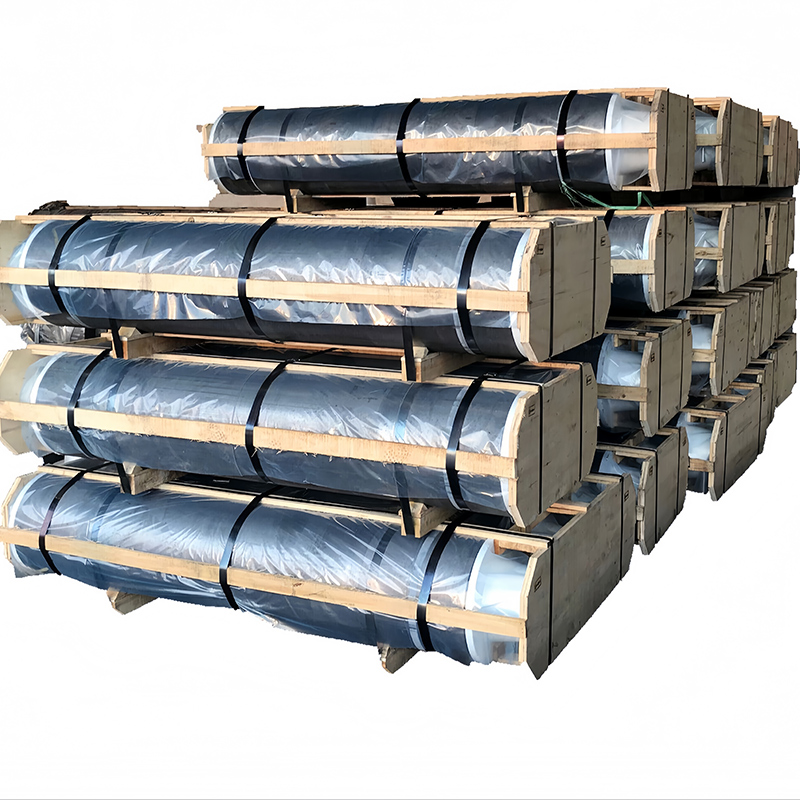

We specialize in producing high-quality CPC from low-sulfur green petroleum coke, tailored for graphite electrode applications. Our production line supports full-range particle sizing, sulfur customization, and SGS-inspected quality control. With high fixed carbon, excellent conductivity, and global shipping capability, we are a preferred CPC supplier for electrode producers, foundries, and aluminum plants worldwide.

Contact us today for technical data sheets, COA, and free samples.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic