Products

Custom Graphite Special-Shaped Parts Precision Machined Graphite Components

Graphite special-shaped parts are vital in metallurgy, casting, semiconductor, PV, and high-temp mold systems due to their excellent conductivity, thermal stability, and chemical resistance.

Description

marker

Product Specifications:

→ Fully Customizable

Scope of Supply:

Graphite plates, graphite rotors, graphite rods, graphite blocks, graphite electrode molds, high-density graphite stirring rods, and other custom-machined components.

Overview

Graphite special-shaped parts are high-performance, precision-engineered components made from premium-grade graphite materials.

These parts are tailored to meet the demands of high-temperature, high-strength, and chemically aggressive environments across industries such as:

● Metallurgy

● Foundry and casting

● Semiconductor and photovoltaic

● Glass mold manufacturing

● Chemical and thermal processing

Key Material Properties

● Extreme Thermal Resistance:Stable at temperatures up to 3000°C in inert or vacuum atmospheres

● Outstanding Electrical Conductivity:Ideal for graphite electrodes and EDM applications

● High Chemical Inertness:Excellent resistance to corrosive chemicals, acids, and alkalis

● Dimensional Stability:Low thermal expansion reduces structural deformation

● Self-Lubricating and Wear-Resistant:Enhances longevity in dynamic environments

Main Applications

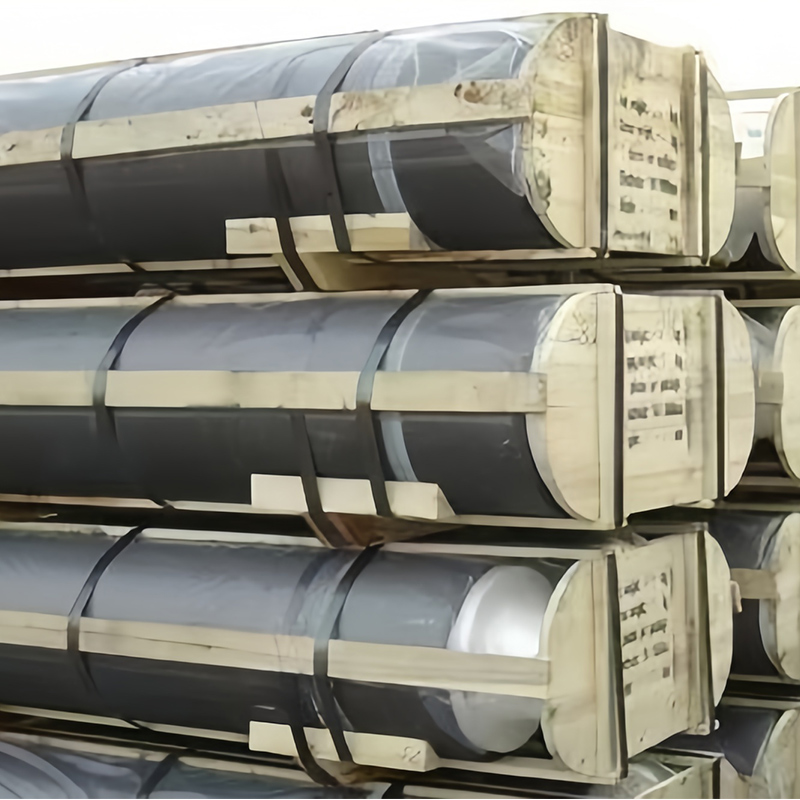

1. Graphite Electrodes & Molds

Used in Electric Arc Furnaces (EAF) and Ladle Furnaces (LF) for steel and alloy manufacturing. Custom molds ensure high dimensional accuracy and electrode durability.

2. Graphite Rotors for Aluminum Degassing

Essential for hydrogen removal and impurity reduction in molten aluminum, improving casting integrity and quality.

3. High-Density Graphite Stirring Rods

Perfect for mixing and homogenizing molten metals. Excellent thermal shock resistance ensures performance under extreme heat.

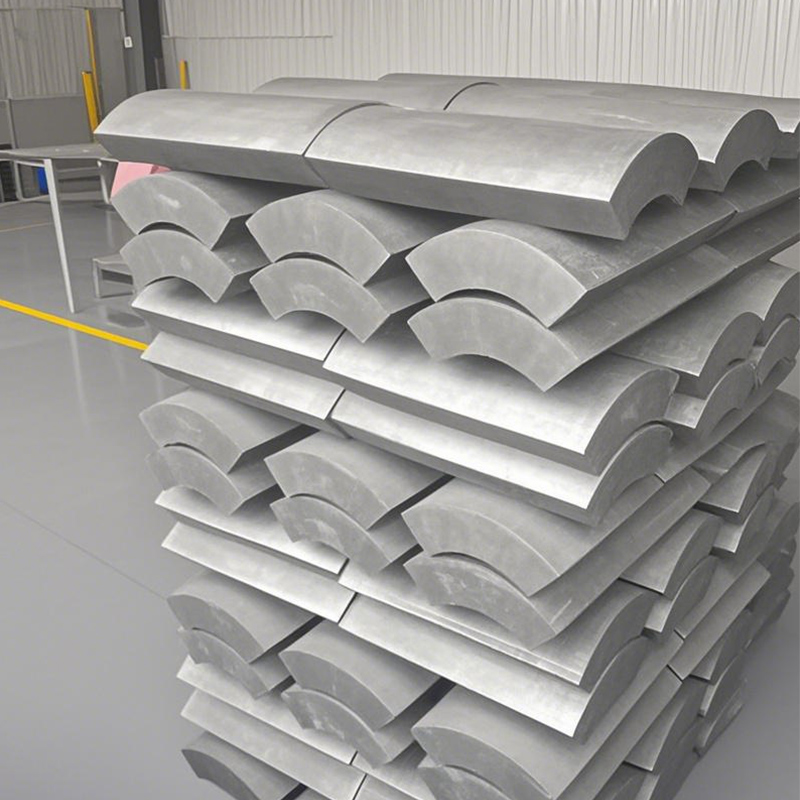

4. Graphite Crucibles & Casting Molds

Used for non-ferrous metals like aluminum, copper, gold, and silver. Provides high thermal conductivity and prevents cracking.

5. Graphite Plates & Insulation Blocks

Applied in high-temperature industrial furnaces and heat treatment lines, as support structures or insulation layers.

6. EDM Graphite Molds

Preferred in automotive and electronics mold-making for their machinability and reliable spark erosion behavior.

Technical Parameters

| Property | Value Range |

| Carbon Purity | ≥ 99% |

| Bulk Density | 1.72 – 1.90 g/cm³ |

| Compressive Strength | ≥ 60 MPa |

| Flexural Strength | ≥ 35 MPa |

| Electrical Resistivity | 8 – 13 μΩ·cm |

| Grain Size | Fine / Medium / Isostatic |

| Thermal Conductivity | 90 – 150 W/m·K |

Material options include: - Isostatically Pressed Graphite

Vibration Molded Graphite

Extruded Graphite

Why Choose Us?

We provide end-to-end solutions based on over 10 years of expertise in graphite electrode production and custom machining. From raw material selection to precision CNC fabrication, our processes are optimized for quality, reliability, and fast delivery.

Whether you’re developing components for high-temperature metallurgy or precision mold manufacturing, we guarantee:

● Tight tolerance machining

● Rapid prototyping

● Scalable production

● International quality standards

Contact us today for customized graphite solutions tailored to your industry’s specifications.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic