Products

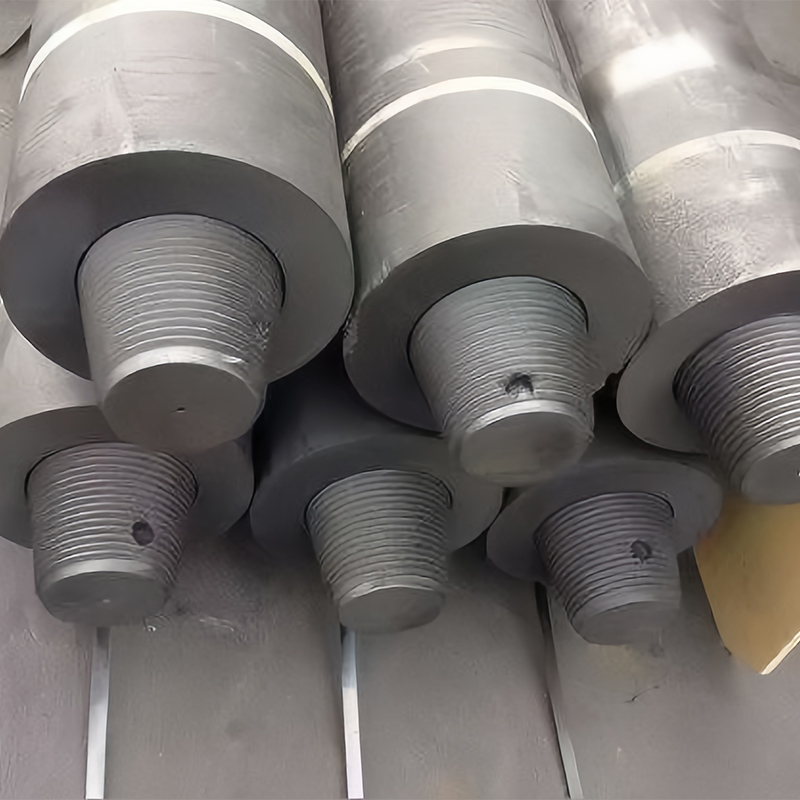

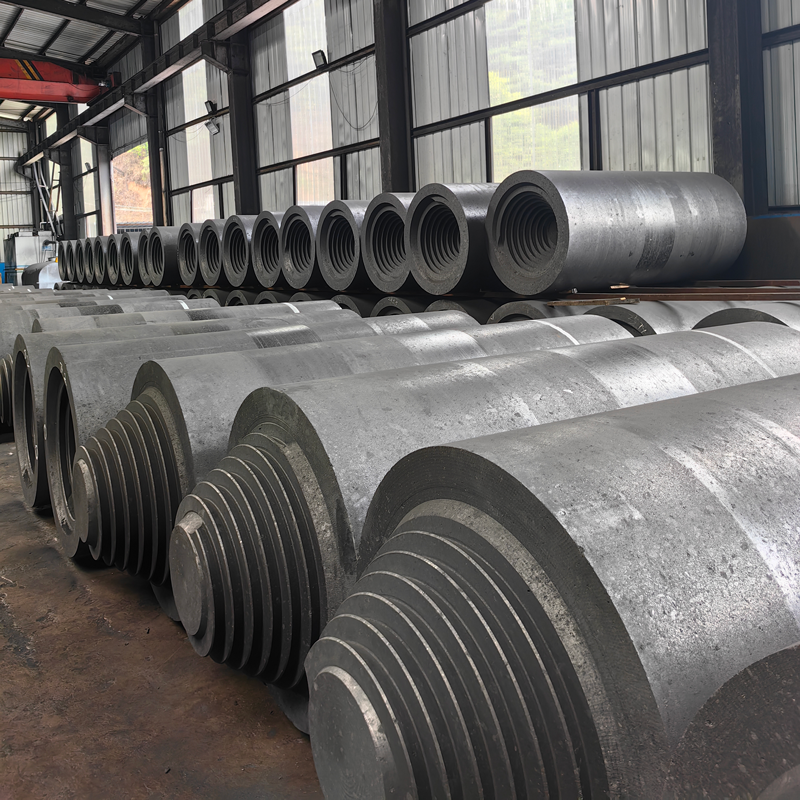

Carbon Electrodes: Professional Overview and Applications

Carbon electrode, it is a product suitable for resistance electric arc furnace. It is suitable for the production of silicon iron, etc. It is an energy-saving updated product for metal smelting. Choosing Carbon electrodes can bring you more economic benefits.

Description

marker

Main Description

Carbon electrodes (graphite electrodes) are essential consumables widely used in metallurgical and industrial processes, primarily serving as conductors in electric arc furnaces (EAF), ladle furnaces (LF), and other high-temperature melting equipment. Manufactured from high-quality petroleum coke and needle coke, these electrodes undergo calcination, molding, baking, vacuum impregnation with binder pitch, and high-temperature graphitization to ensure optimal electrical conductivity, mechanical strength, and thermal stability.

Key Technical Specifications

| Item | Φ500 - Φ700 | Φ750 - Φ950 | Φ1020 - Φ1400 | |||

| Grade | Superior | First Grade | Superior | First Grade | Superior | First Grade |

| Resistivity μΩ·m | ≤40 | ≤45 | ≤40 | ≤45 | ≤40 | ≤45 |

| Bulk Density g/cm³ | 1.52 - 1.62 | 1.52 - 1.62 | 1.52 - 1.62 | |||

| Compressive Strength MPa | 4.0 - 7.5 | 4.0 - 7.5 | 3.5 - 7.0 | |||

| Bending Strength MPa | ≥18.0 | ≥18.0 | ≥18.0 | |||

| CTE 10⁻⁶/°C (20-1000°C) | 3.8 - 5.0 | 3.6 - 4.8 | 3.6 - 4.8 | |||

| Ash Content % | 1.0 - 2.5 | 1.0 - 2.5 | 1.0 - 2.5 | |||

Allowable Current Density

| Nominal Diameter mm | Allowable Current A | Current Density A/cm² |

| Φ700 - Φ780 | 44000 - 50000 | 5.7 - 6.5 |

| Φ800 - Φ920 | 50000 - 56000 | 5.5 - 6.3 |

| Φ960 - Φ1020 | 53000 - 61000 | 5.0 - 6.1 |

| Φ1250 | 63000 - 70000 | 5.0 - 5.7 |

Manufacturing Process

Carbon electrodes are produced through a rigorous multi-step process involving:

● Raw Material Selection:Use of high-purity petroleum and needle coke to ensure low impurity and ash content.

● Calcination:Removal of volatile substances to enhance carbon purity.

● Forming and Baking:Compression molding followed by baking at high temperatures to develop structural integrity.

● Vacuum Impregnation:Use of binder pitch under vacuum to increase density and reduce porosity.

● Graphitization:Graphitized at temperatures exceeding 2800°C in specialized furnaces to convert carbon into graphite, significantly improving electrical and thermal properties.

Applications

● Electric Arc Furnace Steelmaking (EAF):Carbon electrodes serve as the conductive medium generating electric arcs to efficiently melt scrap steel with minimal energy loss.

● Ladle Furnace Refining (LF):Provides precise temperature control and refining during secondary steelmaking.

● Non-Ferrous Metal Smelting:Widely used in aluminum, copper, and other metal melting processes requiring stable electrical performance.

● Chemical Industry:Applied in electrolysis, electrochemical synthesis, and battery manufacturing processes.

Advantages

● High Electrical Conductivity:Minimizes resistive losses and enhances furnace efficiency.

● Thermal Shock Resistance:Maintains structural integrity under rapid temperature fluctuations.

● Mechanical Strength:Reduces breakage risk during handling and operation.

● Low Ash Content:Prevents contamination and maintains metal purity.

● Long Service Life:Improves cost-effectiveness and reduces downtime.

Summary

Carbon electrodes, particularly graphite electrodes, are indispensable components in modern metallurgical operations, offering superior electrical, mechanical, and thermal performance under demanding conditions. Their optimized manufacturing process and stringent quality control ensure consistent reliability, energy efficiency, and improved metal quality, making them fundamental for steel and non-ferrous metal production worldwide.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic