Products

Graphite Rods – Engineered for High-Temperature and Electrode Applications

Graphite rods are widely applied in electric arc furnace (EAF) steelmaking, EDM machining, vacuum and resistance furnace heating, high-temperature alloy casting, electrolytic and plating processes, solar photovoltaic, lithium battery, and hydrogen energy systems. With excellent electrical conductivity, thermal resistance, and chemical stability, they are ideal materials for advanced industrial applications requiring high-temperature endurance and precision conductivity.

Description

marker

Product Overview

Our high-purity graphite rods are manufactured from premium petroleum coke and needle coke, processed through precision extrusion, baking, and high-temperature graphitization under controlled conditions. These graphite rods deliver excellent thermal conductivity, electrical performance, chemical resistance, and mechanical strength, making them ideal for a wide range of industrial applications.

Graphite Rod Specification (Industry Standard)

| Item | Unit | Range/Specification |

| Density | g/cm³ | 1.70 ~ 1.85 |

| Compressive Strength | MPa | ≥ 35 |

| Bending Strength | MPa | ≥ 15 |

| Electrical Resistivity | μΩ·m | 8 ~ 13 |

| Thermal Conductivity | W/m·K | 80 ~ 120 |

| Operating Temperature | ℃ | ≤ 3000 (in inert atmosphere) |

| Ash Content | % | ≤ 0.1 |

| Thermal Expansion Coefficient | 10⁻⁶/°C | ≤ 4.5 |

| Grain Size | μm | 10 ~ 30 |

| Diameter Range | mm | Φ50 ~ Φ500 |

| Length Range | mm | 100 ~ 2000 (customizable) |

All products comply with ISO 9001 quality standards and can be manufactured to meet GB/T 1429 or customer-specific requirements.

Industrial Applications:

●Electric Arc Furnaces (EAF): Graphite rods are commonly machined into electrodes for steel and ferroalloy production.

●Vacuum and Resistance Furnaces: Used as heating elements or structural parts due to high thermal stability.

●Chemical Processing: Electrodes in electrolysis, electroplating, and acid-alkali environments.

●EDM (Electrical Discharge Machining): Widely used in toolmaking, molds, and precision part fabrication.

●Non-ferrous Metal Casting: Used for sintering molds, die-casting cores, and casting crucibles.

●R&D and Lab Equipment: Ideal for crucibles, reaction tubes, and thermal insulation parts.

●Emerging Applications: Growing usage in photovoltaic production, lithium-ion battery anodes, and hydrogen energy systems.

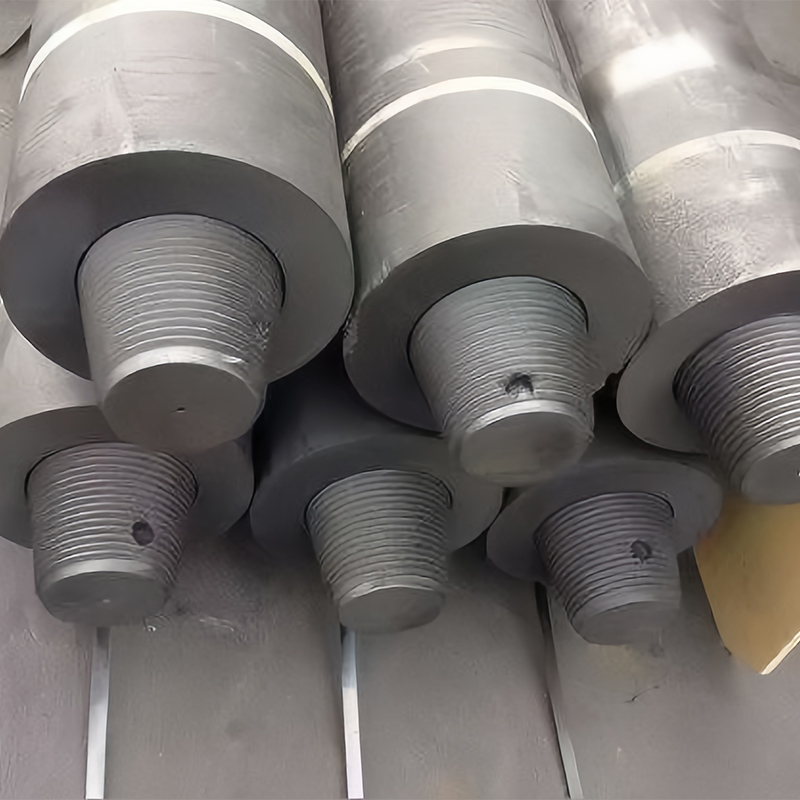

Distinction: Graphite Rod vs Graphite Electrode

While both are manufactured from synthetic graphite, graphite rods are typically semi-finished or raw forms, used as structural or conductive elements. Graphite electrodes, on the other hand, are precision-machined rods with threaded nipples designed specifically for use in EAF and ladle furnaces. Our graphite rods can be further machined into electrodes or customized parts based on client application needs.

Summary

Our high-density graphite rods are trusted across metallurgy, precision machining, chemical processing, and emerging clean energy industries. With customizable sizes, consistent conductivity, and exceptional thermal stability, they represent the optimal solution for demanding industrial environments.

Feel free to contact our engineering team for detailed technical consultation, sample support, or a tailored quotation. We offer OEM manufacturing, global logistics, and full technical support.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic