Products

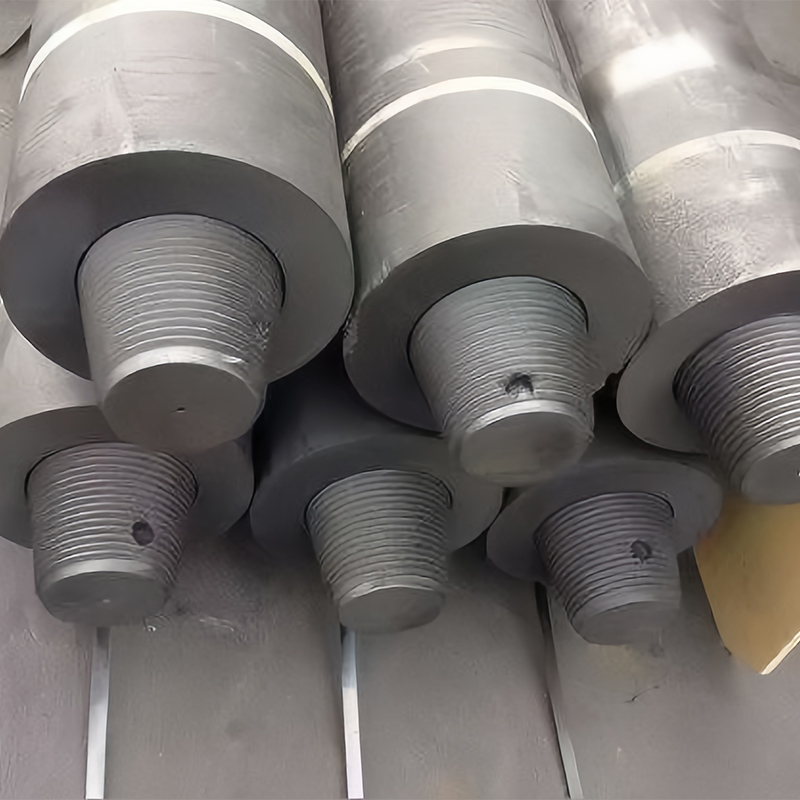

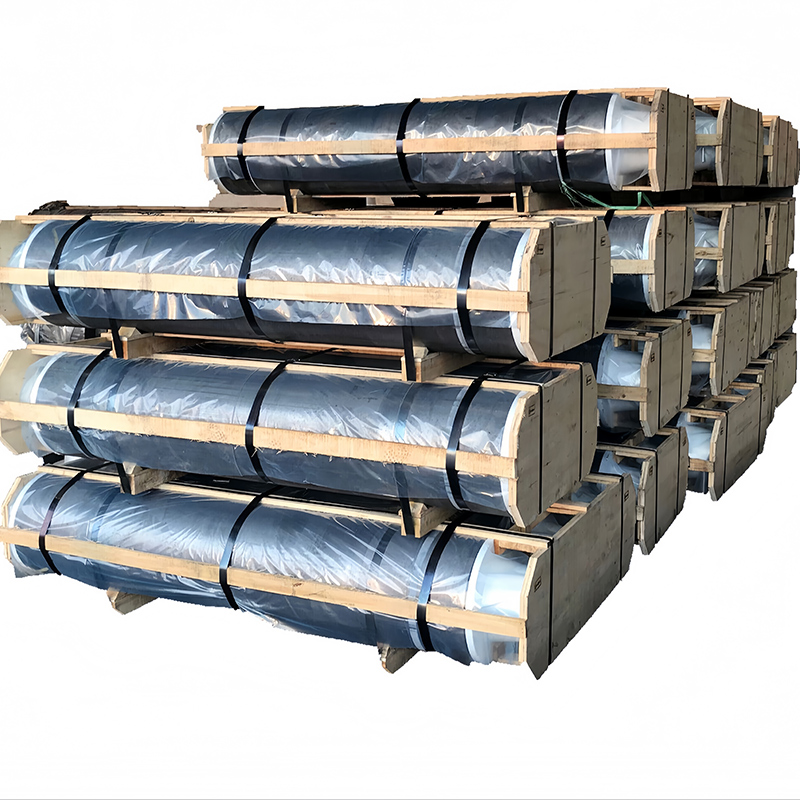

Graphite Scrap Product Specifications – High-Purity Carbon Material for Graphite Electrodes

High-purity graphite scrap is widely used in electric arc furnace and ladle furnace electrode manufacturing, enhancing electrode conductivity and thermal resistance for efficient smelting and sustainable recycling.

Description

marker

Product Overview

Our graphite scrap is a premium-grade raw material specifically designed for the production and recycling of graphite electrodes used in electric arc furnaces (EAF), ladle furnaces, and other high-temperature metallurgical applications. Featuring high carbon content and tightly controlled impurity levels, this graphite scrap delivers excellent electrical conductivity, thermal stability, and mechanical strength, making it an ideal feedstock for electrode manufacturing and related carbon-based applications.

Technical Specifications

| Parameter | Target Value | Available Particle Sizes | Packaging Options |

| Carbon Content (C) | ≥ 98.5% | 0–1 mm / 0–2 mm / 1–8 mm / 2–8 mm | Ton bags / bulk packaging / customized packaging |

| Sulfur Content (S) | ≤ 0.5% | ||

| Moisture Content | ≤ 0.2% | ||

| Volatile Matter | ≤ 0.5% | ||

| Ash Content | ≤ 0.8% (customizable) | ||

| Electrical Resistivity | ≤ 120 μΩ·m |

Product Description and Applications

Our graphite scrap contains ultra-high carbon purity (≥98.5%) with minimal impurities such as sulfur and ash, which are critical for ensuring superior electrical and thermal performance in graphite electrodes. The low moisture and volatile matter content further enhance the material’s stability under high-temperature operating conditions.

The graphite scrap is available in multiple particle size ranges—from fine powders (0–1 mm) to coarse granules (2–8 mm)—to meet diverse processing requirements such as baking paste preparation, briquetting, or direct electrode manufacturing.

Key Applications:

Electric Arc Furnace (EAF) Electrodes: Used as a key raw material for producing electrodes with excellent electrical conductivity and resistance to thermal cycling.

Ladle Furnace Electrodes: Suitable for electrodes applied in ladle refining, where stability under variable electrical loads is essential.

Graphitized Carbon Products: Used in the manufacture of carbon brushes, refractory materials, and other carbon-based industrial components requiring high purity graphite.

Graphite Recycling: Ideal for reclaiming and reprocessing graphite electrodes, promoting sustainable manufacturing and cost efficiency.

Professional Highlights and SEO Keywords

Our graphite scrap excels in electrical conductivity, thermal shock resistance, and chemical inertness—all vital properties for graphite electrodes in steelmaking and other metallurgical sectors.

Customizable ash content and particle size distribution ensure compliance with stringent industrial standards and enhance the performance of finished electrodes. The low sulfur content reduces the risk of corrosion and contamination during electrode operation.

Why Choose Our Graphite Scrap?

● Consistent Quality Control:Rigorous testing ensures compliance with industry standards, optimizing electrode performance and lifespan.

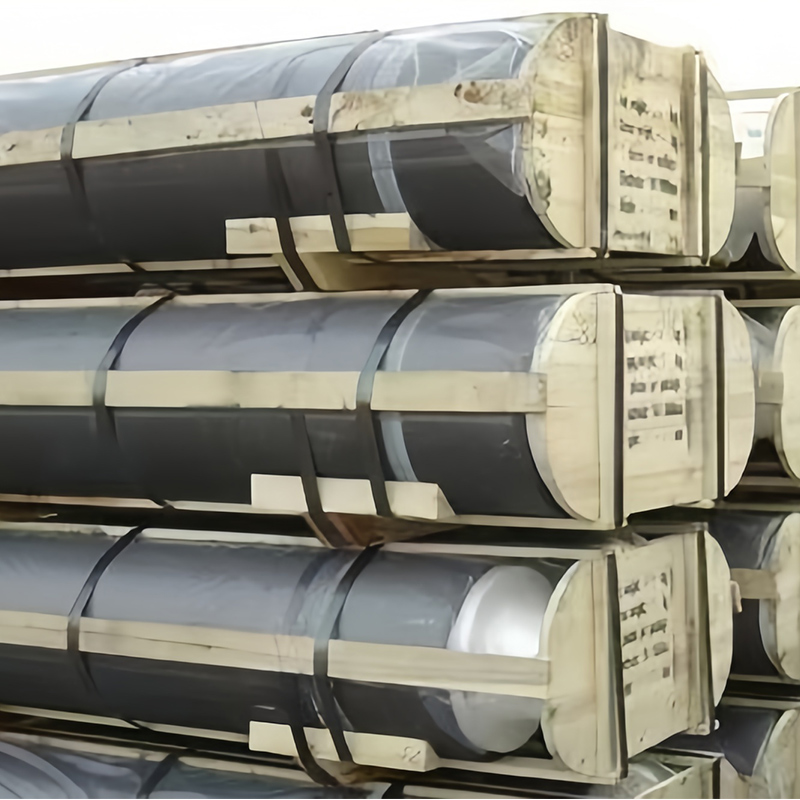

● Versatile Packaging:Flexible packaging options—from bulk ton bags to customized sizes—streamline logistics and inventory management.

● Sustainability Focus:Supports circular economy practices through efficient graphite recycling and raw material conservation.

● Technical Support:Our expert team offers consultation on material selection and processing parameters tailored to your production needs.

For inquiries regarding graphite scrap tailored for graphite electrode manufacturing or to request samples and technical datasheets, please contact our sales team. We are dedicated to providing premium carbon materials that empower your metallurgical processes with efficiency and reliability.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic