Products

Graphitized Petroleum Coke (GPC)

GPC is essential in UHP graphite electrode production, steel recarburizing, battery anodes, and aluminum cathodes, offering ultra-low sulfur, high purity, excellent conductivity, and thermal stability for advanced metallurgical and energy industries.

Description

marker

Basic Description

High-Purity Carbon Additive for Graphite Electrode and Metallurgical Applications

Graphitized Petroleum Coke (GPC) is a high-quality carbon material produced by graphitizing Calcined Petroleum Coke (CPC) at temperatures above 2800°C. The process significantly improves carbon crystallinity, reduces sulfur and nitrogen content, and enhances electrical conductivity and thermal shock resistance. GPC is an essential raw material for ultra-high power (UHP) graphite electrode production and serves as a clean carbon source in various high-temperature metallurgical processes.

Key Technical Parameters

| Property | Typical Values |

| Fixed Carbon | ≥ 98.5% – 99.9% |

| Sulfur Content | ≤ 0.05% (Ultra-low sulfur available) |

| Nitrogen Content | ≤ 300 ppm |

| Volatile Matter | ≤ 0.3% |

| Ash Content | ≤ 0.2% |

| True Density | 2.18 – 2.26 g/cm³ |

| Electrical Resistivity | ≤ 20 μΩ·m |

| Particle Size | 0–1mm, 1–5mm, or customized |

Ultra-low sulfur GPC enhances the performance and service life of UHP graphite electrodes by minimizing electrical resistance and preventing impurity contamination.

Key Benefits

● High Carbon Yield

Boosts carburization efficiency with minimal slag formation.

● Ultra-Low Sulfur & Nitrogen

Critical for producing clean steels, special alloys, and reducing environmental burden.

● Superior Conductivity & Purity

Ideal for graphite electrode production, improving conductivity and thermal resistance.

● Graphite-Like Crystalline Structure

Delivers high temperature resistance and dimensional stability.

● Custom Particle Size Distribution

Enables targeted use in electrodes, foundries, aluminum smelting, and battery materials.

Applications

1.Graphite Electrode Manufacturing

GPC is the primary feedstock for UHP graphite electrodes used in electric arc furnaces (EAF) and ladle furnaces (LF). Its low ash content and superior conductivity ensure stable arc performance and prolonged electrode life.

2.Steel & Iron Industry as Recarburizer

Used in foundries and steel mills for carbon adjustment in molten metal. Especially effective in ductile iron and low-sulfur steel grades.

3.Battery and Conductive Materials

Serves as precursor for synthetic graphite in lithium-ion battery anodes and conductive carbon additives.

4.Cathodes & Carbon Blocks

Key ingredient in aluminum electrolysis cathodes and carbon block products requiring high purity.

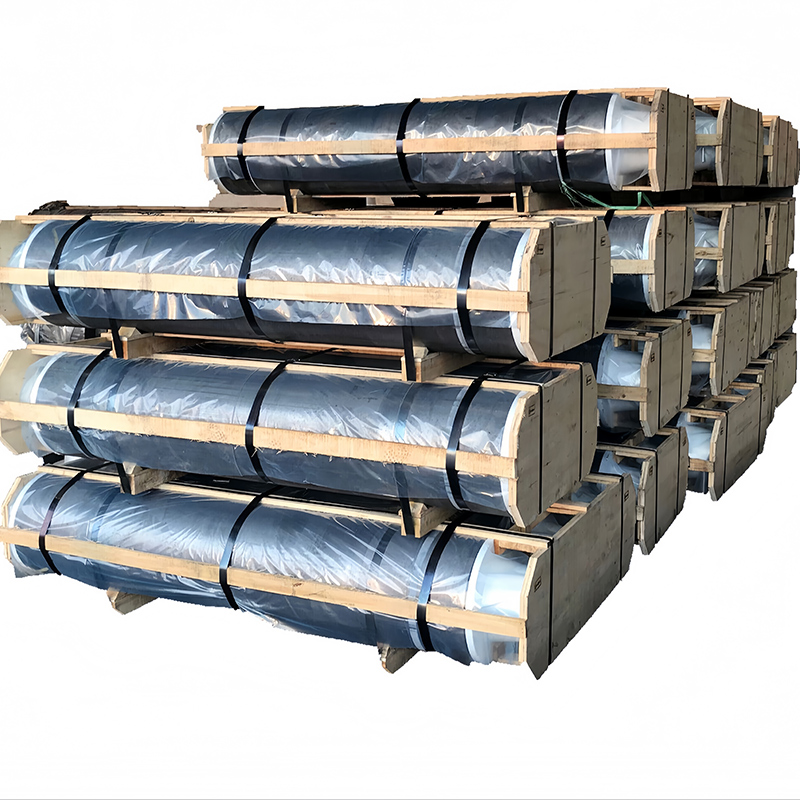

Packaging & Logistics

● Packaging: 25kg PE bags, 1000kg jumbo bags, or as per request

● Lead Time: 7–15 days based on quantity

● Export Markets: EU, MENA, Southeast Asia, USA, South Korea

Why Choose Our GPC?

Our GPC features stable quality, low sulfur (<0.03%), high carbon content, and consistent particle sizing. It meets ISO and SGS standards, trusted by global users in the steel, electrode, aluminum, and energy storage industries

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic