Products

High-Purity Graphite Blocks — Precision Carbon Materials for Electrode, Metallurgy, and Thermal Processing Industries

High-purity graphite blocks are essential in UHP electrode manufacturing, EDM machining, vacuum furnace components, and monocrystalline silicon thermal systems—ideal for demanding high-temperature, conductive industrial environments.

Description

marker

Basic Description

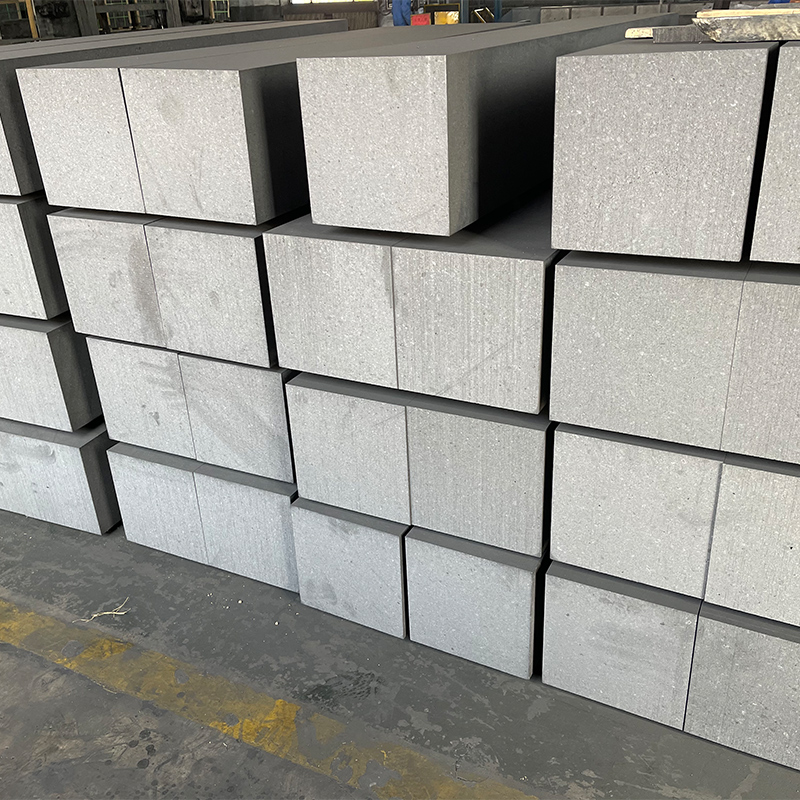

Graphite blocks—also referred to as graphite billets or blanks—are essential materials extensively used in high-temperature, high-conductivity, and chemically intensive industrial applications. Manufactured from premium raw materials such as petroleum coke, needle coke, and coal tar pitch, these blocks undergo calcination, molding, and high-temperature graphitization processes to achieve optimal performance.

Key Material Characteristics

Graphite blocks are engineered to meet demanding requirements involving thermal resistance, electrical conductivity, mechanical integrity, and chemical inertness.

Based on usage, they are categorized by forming method:

● Isostatic graphite blocks: Fine grain (<15μm), homogeneous density, ideal for high-precision machining.

● Molded graphite blocks: Medium grain, cost-effective, commonly used in general refractory and electrode applications.

● Vibration molded graphite blocks: Large-size format, excellent strength, suited for furnace linings and heavy-duty thermal components.

Technical Parameters (Typical Values)

| Property | Typical Range |

| Apparent Density | 1.75 – 1.91 g/cm³ |

| Compressive Strength | ≥40 MPa |

| Flexural Strength | ≥25 MPa |

| Electrical Resistivity | 6 – 12 μΩ·m |

| Thermal Conductivity | 90 – 170 W/m·K |

| Ash Content (Purity) | ≤0.1% (Ultra-pure: <50 ppm) |

| Max Operating Temperature | Up to 3000°C (in inert/vacuum atmospheres) |

| Grain Size | Ultra-fine (<10μm) to coarse (>0.8mm) |

Note: Custom specifications available upon request.

Real-World Industrial Applications

1. Graphite Electrode Manufacturing

Graphite blocks serve as blanks for machining specialized shapes in UHP graphite electrodes and large-diameter electrodes for electric arc furnaces (EAF) and ladle furnaces (LF).

2. EDM & CNC Machining

Fine-grain isostatic graphite blocks are widely used in Electrical Discharge Machining (EDM) applications across mold-making, aerospace, and automotive sectors, offering excellent machinability and wear resistance.

3. Furnace Construction & Components

Large molded or vibration-molded graphite blocks are applied as structural parts, hearth blocks, insulation elements, and crucible supports in high-temperature vacuum furnaces and sintering kilns.

4. Semiconductor & Photovoltaics

Ultra-pure graphite blocks play a crucial role in monocrystalline silicon production, wafer thermal processing, and cleanroom furnace environments where ultra-low impurity levels are critical.

5. Non-Ferrous Metal Casting

Used as casting molds, dies, and contact elements for aluminum, copper, zinc, and rare-earth alloys, graphite blocks improve thermal efficiency and anti-corrosion performance.

Custom Machining & Engineering Support

Our graphite blocks can be custom-manufactured with: - Tailored dimensions: According to client drawings - Precision CNC machining: Tolerances down to ±0.02 mm - Surface enhancements: Anti-oxidation coatings, resin impregnation - Engineering assistance: 2D/3D modeling and technical consulting

Our production lines support both bulk industrial orders and precision-finished parts for niche markets.

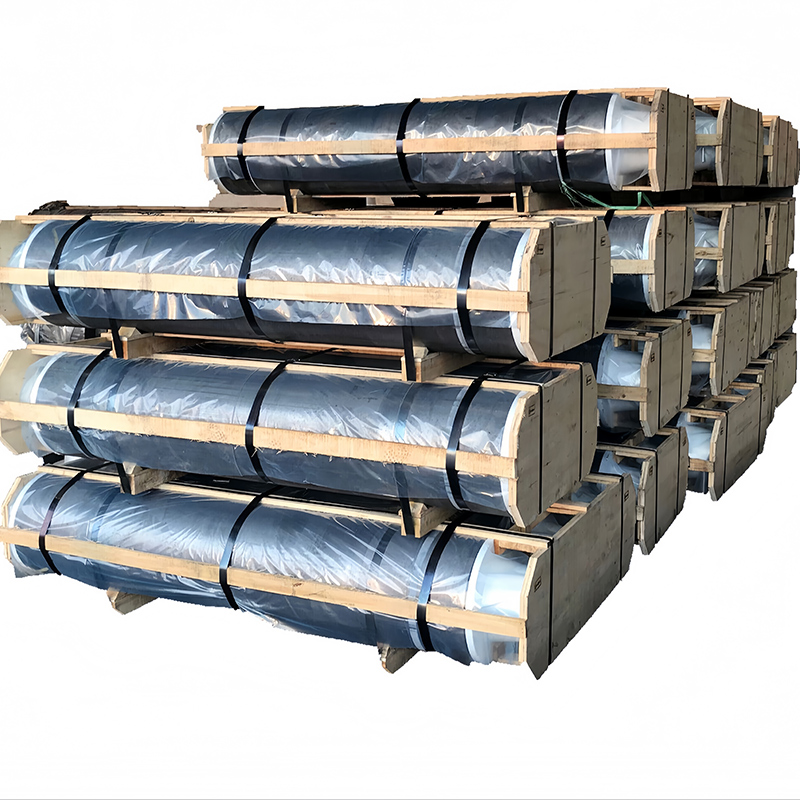

Global Delivery & Industrial Integration

We supply graphite blocks globally to industries including: - Steel & metallurgy - Semiconductor & solar energy - Aerospace & defense - Laboratory and thermal R&D

Summary

Graphite blocks represent a vital extension of carbon materials derived from electrode-grade technology. Combining thermal endurance, mechanical stability, and customizability, they enable high-performance solutions across industrial and high-tech applications. We deliver consistent quality, engineering support, and global service.

Contact us today for material samples, data sheets, or technical consultation tailored to your application.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic