Products

High-Purity Graphite Crucibles for Industrial Melting and Electrode Applications

Graphite crucibles are ideal for high-temperature melting of aluminum, copper, gold, and silver. Suitable for vacuum and induction furnaces, they offer thermal stability and strong chemical resistance.

Description

marker

Basic Description

Graphite crucibles, engineered using high-purity synthetic graphite, are essential components in high-temperature industries such as metallurgy, non-ferrous metal casting, induction heating systems, and laboratory analysis. Closely related to the production of graphite electrodes, these crucibles leverage similar base materials—high-density carbon and fine-grain graphite—to offer exceptional performance under extreme thermal conditions.

Material Composition and Manufacturing Process

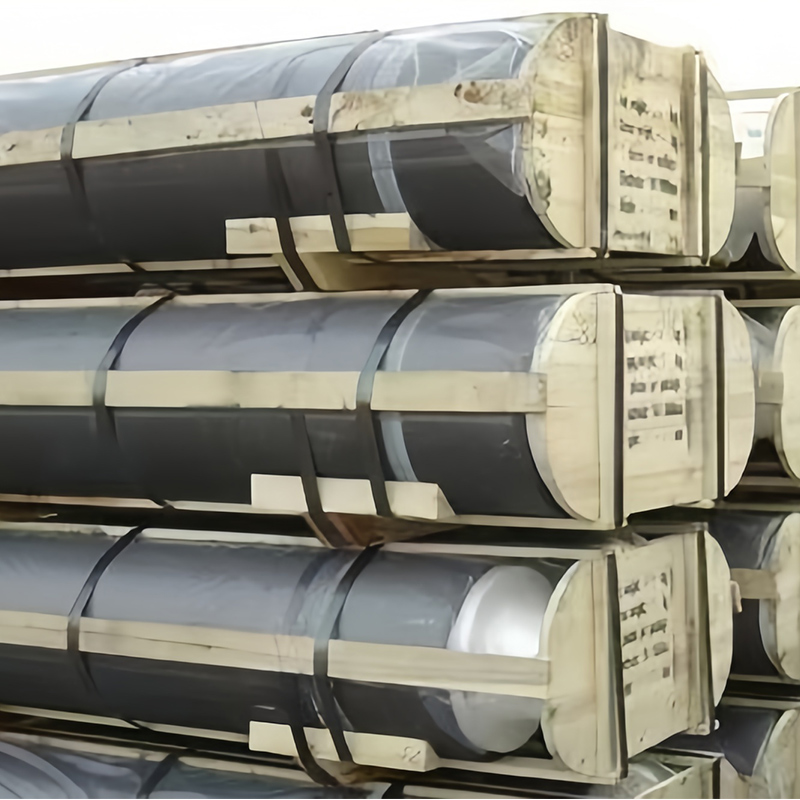

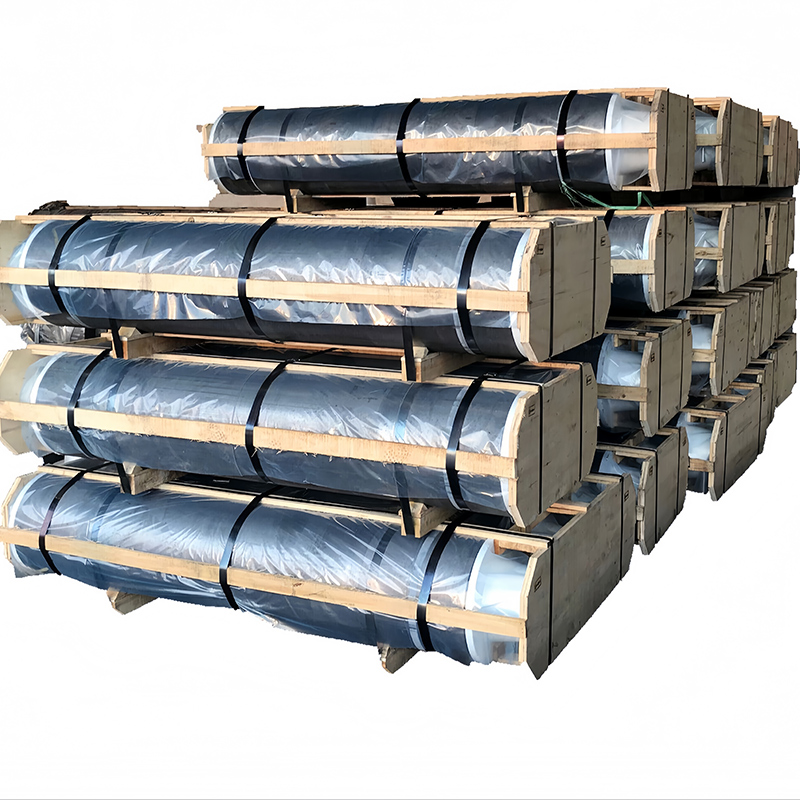

Graphite crucibles are primarily produced using isostatically pressed graphite, vibration-molded graphite, or extruded graphite, each selected based on specific end-use requirements. These materials often overlap with the raw materials used in graphite electrode production, though crucibles are further treated for enhanced oxidation resistance and purity.

Key Properties:

● High Thermal Shock Resistance– Withstands rapid temperature changes without structural failure.

● Excellent Thermal Conductivity– Enables uniform heating and efficient energy transfer.

● Chemical Stability– Resists corrosive attack from molten metals and slags.

● Low Coefficient of Thermal Expansion– Maintains dimensional stability up to 3000°C (in inert or vacuum conditions).

● Low Ash Content– Typically ≤0.1%, with ultra-high purity variants <50 ppm for semiconductor and solar applications.

Technical Specifications (Typical Range)

| Parameter | Value Range |

| Bulk Density | 1.75 – 1.85 g/cm³ |

| Porosity | ≤12% |

| Flexural Strength | ≥20 MPa |

| Compressive Strength | ≥40 MPa |

| Thermal Conductivity | 100 – 160 W/m·K |

| Maximum Operating Temp | Up to 3000°C (inert/vacuum) |

| Grain Size Options | Fine (<10 μm) to Coarse (>0.8 mm) |

Industrial Applications

1. Metal Melting & Casting

Used for smelting non-ferrous metals such as aluminum, copper, gold, silver, and brass in both induction furnaces and resistance heating furnaces.

2. Vacuum and Induction Furnaces

Preferred in vacuum sintering and medium to high frequency induction melting applications, due to low outgassing and high purity.

3. Analytical and Lab Testing

Essential for chemical analysis, ash testing, and material purity validation where contamination must be minimized.

4. Solar and Semiconductor Industries

Ultra-high purity crucibles are used in Czochralski (CZ) crystal pulling for silicon ingots and in semiconductor wafer production.

5. Graphite Electrode Support

In large-scale electric arc furnaces (EAFs), graphite crucibles are often paired with graphite electrodes in bottom-pour or specialty melting setups for enhanced conductivity and structural support.

Customization & CNC Machining

As a professional manufacturer of graphite electrodes and crucibles, we offer: - Custom OD/ID sizes, wall thickness, and height - CNC machining with precision tolerances up to ±0.02 mm - Anti-oxidation coating for prolonged crucible life - Graphite crucibles with threaded or flanged ends for specialized furnace integration

We serve global clients in metallurgy, aerospace, chemical engineering, battery, and photovoltaic sectors.

Summary

Graphite crucibles are engineered for demanding thermal applications where durability, conductivity, and purity are paramount. By leveraging similar materials and processes as graphite electrode production, these crucibles ensure performance stability in critical melting, casting, and refining environments. Our company provides complete customization, rapid production, and technical support for clients worldwide.

Contact us today for specifications, samples, or OEM/ODM inquiries. Worldwide delivery available.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic