Products

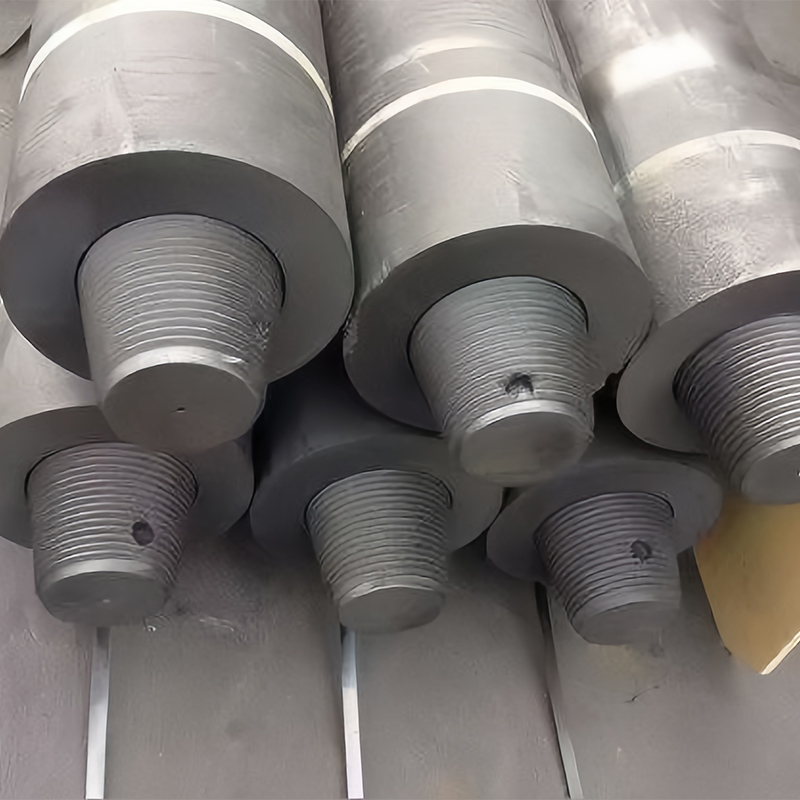

Graphite Electrode Nipples

Graphite electrode nipples are critical components used to connect sections of electrode columns, widely applied in high-temperature industrial equipment such as Electric Arc Furnaces (EAF), Ladle Furnaces (LF), and Submerged Arc Furnaces (SAF).

Graphite Electrode

Company Overview Our company mainly produces Ø200mm to Ø1400mm graphite electrodes in Regular Pow...

Ultra High Power (UHP) Graphite Electrodes

UHP graphite electrodes are widely used in electric arc furnace steelmaking, offering high conductivity, excellent heat resistance, and mechanical strength, significantly improving smelting efficiency and product quality, making them essential in modern steel production.

650mm / 700mm UHP Graphite Electrode

The 650mm and 700mm UHP graphite electrodes are essential for large-scale EAF and LF operations, enabling efficient scrap melting and precise steel refining. Their superior electrical conductivity, thermal resistance, and mechanical strength ensure reliable performance under extreme industrial conditions, making them critical for improving output and steel quality in modern metallurgy.

600mm UHP Graphite Electrode

The 600mm UHP graphite electrode is widely used in electric arc furnaces (EAF) and ladle furnaces (LF), suitable for high-temperature and high-load operations. With excellent electrical conductivity, thermal shock resistance, and low consumption, it is ideal for melting scrap, DRI, and non-ferrous metals, making it a preferred choice for advanced metallurgical applications.

550mm UHP Graphite Electrode

The 550mm UHP graphite electrode, known for its excellent conductivity and thermal stability, is widely applied in electric arc furnaces (EAF) and ladle furnaces (LF). It supports efficient, stable melting and refining of steel and non-ferrous metals, significantly improving melting speed and energy efficiency while ensuring metal purity and product quality. It is a core consumable in modern metallurgical production, meeting the stringent demands of large-scale steel and non-ferrous metal plants.

500mm UHP Graphite Electrode

The 500mm Ultra High Power (UHP) graphite electrode is a key consumable widely used in electric arc furnace (EAF) steelmaking and high-temperature metallurgy. Its excellent electrical conductivity and thermal shock resistance enable efficient melting and secondary refining, improving production efficiency and steel quality.

450mm UHP Graphite Electrode Technical Overview

The 450mm Ultra High Power (UHP) graphite electrode is a critical consumable widely used in electric arc furnace (EAF) steelmaking, ladle refining, and non-ferrous metallurgy. It delivers excellent electrical conductivity, thermal shock resistance, and mechanical strength to optimize furnace performance and steel quality.

400mm UHP Graphite Electrode – Advanced Ultra High Power Solution for Metallurgical Furnaces

The 400mm UHP graphite electrode is engineered for heavy-duty Electric Arc Furnaces (EAF), Ladle Furnaces (LF), and Submerged Arc Furnaces (SAF). It offers superior conductivity and thermal shock resistance, enabling rapid melting, reduced electrode consumption, and enhanced steel quality in advanced steel and alloy production.

Graphite Electrodes

Hebei Ruitong Carbon Co., Ltd, was founded in July 1985. We offer a range of carbon production from raw materials to finished products. We mainly produce various types of carbon products, such as RP graphite electrodes, HP graphite electrodes, UHP graphite electrodes, graphite crucibles, graphite scrap, carbon additive among others.We use premium quality raw materials and rigorous quality testing equipment to ensure the high level of production standards.

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic