Products

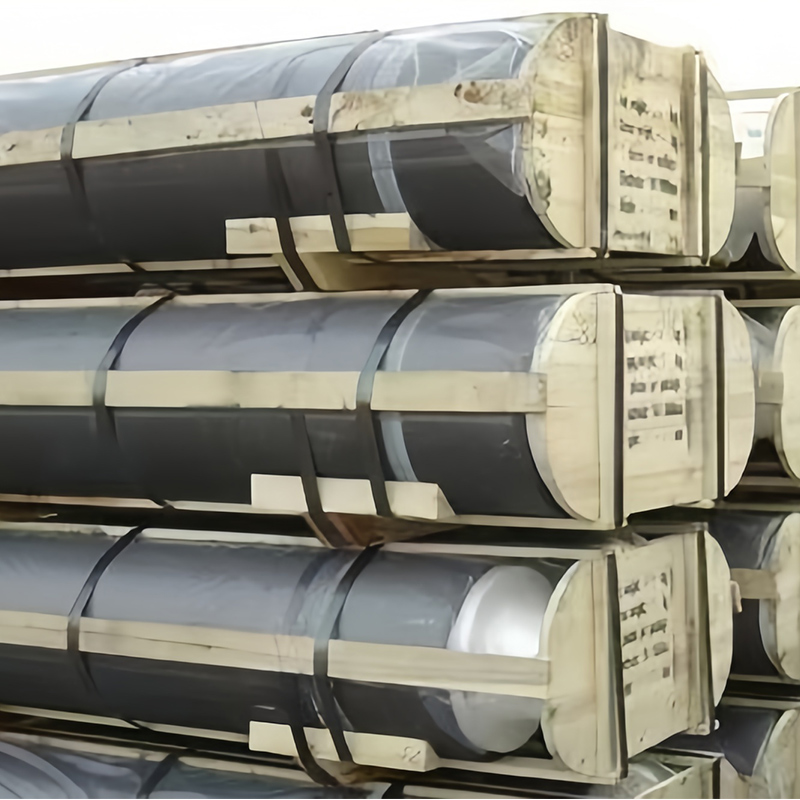

550mm RP Graphite Electrode — High-Performance Solution for Large-Capacity Electric Arc Furnaces

Ideal for large-capacity electric arc furnaces (EAF), ladle furnaces (LF), and submerged arc furnaces (SAF). Widely used in high-output steel plants and ferroalloy production, especially for facilities exceeding 700,000 tons annually aiming to reduce electrode consumption and improve process stability.

500mm RP Graphite Electrode — Advanced Performance for Large-Scale Electric Arc Furnaces

The 500mm RP graphite electrode is designed for large-capacity EAFs, offering superior conductivity, mechanical strength, and thermal stability. Advanced manufacturing ensures low resistivity and high thermal resistance, reducing electrode consumption and boosting steelmaking efficiency—a cost-effective solution.

450mm RP Graphite Electrode — Optimized Conductivity and Cost-Effective Performance for Large Electric Arc Furnaces

The 450mm RP graphite electrode is engineered for large electric arc furnaces, offering high conductivity, excellent oxidation resistance, and thermal stability. Advanced manufacturing ensures low resistivity and strong mechanical strength, reducing electrode consumption per ton and boosting production efficiency—an ideal choice for cost-effective steelmaking.

400mm RP Graphite Electrode-Engineered for Stable Conductivity and Mechanical Integrity in High-Volume EAF Steelmaking

The 400mm RP (Regular Power) graphite electrode is engineered for electric arc furnaces (EAF) operating under standard power conditions. It offers reliable current conductivity, arc stability, and mechanical integrity, making it well-suited for carbon and alloy steel production facilities with annual outputs exceeding 500,000 metric tons.

350mm Regular Power (RP) Graphite Electrode — Enhanced Efficiency for Medium-Capacity Electric Arc Furnaces

The 350mm RP graphite electrode offers a strong balance of conductivity, thermal stability, and cost-efficiency. Designed for medium-capacity EAFs, it performs reliably in continuous steelmaking and ferroalloy production. A smart choice for reducing energy use and improving operational stability.

300mm Regular Power (RP) Graphite Electrode — Reliable Solution for Small to Medium Electric Arc Furnaces

The 300mm RP graphite electrode offers a cost-effective and stable solution for small to medium-sized EAFs, delivering reliable conductivity and excellent oxidation resistance for the production of carbon steel, silicon, and phosphorus.

HP Graphite Electrodes

HP graphite electrodes are widely used in electric arc furnace steelmaking, metallurgical processes, and high-temperature electrolysis. Their excellent conductivity and heat resistance significantly improve smelting efficiency and product quality, making them essential in modern metallurgy.

600mm High Power (HP) Graphite Electrode — Engineered for Ultra-Heavy-Duty Furnace Applications

The 600 mm high-power graphite electrode is engineered specifically for large-scale electric arc furnaces (EAF) and submerged arc furnaces (SAF). It delivers outstanding electrical conductivity, oxidation resistance, and thermal stability, making it a reliable and efficient choice for extreme high-temperature metallurgy.

550mm High Power Graphite Electrode (HP) — Custom-Engineered for High-Load Applications

The 550mm high-power graphite electrode is a custom, non-standard product tailored for large-capacity submerged arc furnaces (SAF). It offers exceptional thermal stability, electrical conductivity, and mechanical strength, widely used in extreme smelting conditions such as manganese alloy production.

Products

Hebei Ruitong Carbon Co., Ltd, was founded in July 1985. We offer a range of carbon production from raw materials to finished products. We mainly produce various types of carbon products, such as RP graphite electrodes, HP graphite electrodes, UHP graphite electrodes, graphite crucibles, graphite scrap, carbon additive among others.We use premium quality raw materials and rigorous quality testing equipment to ensure the high level of production standards.

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic