Products

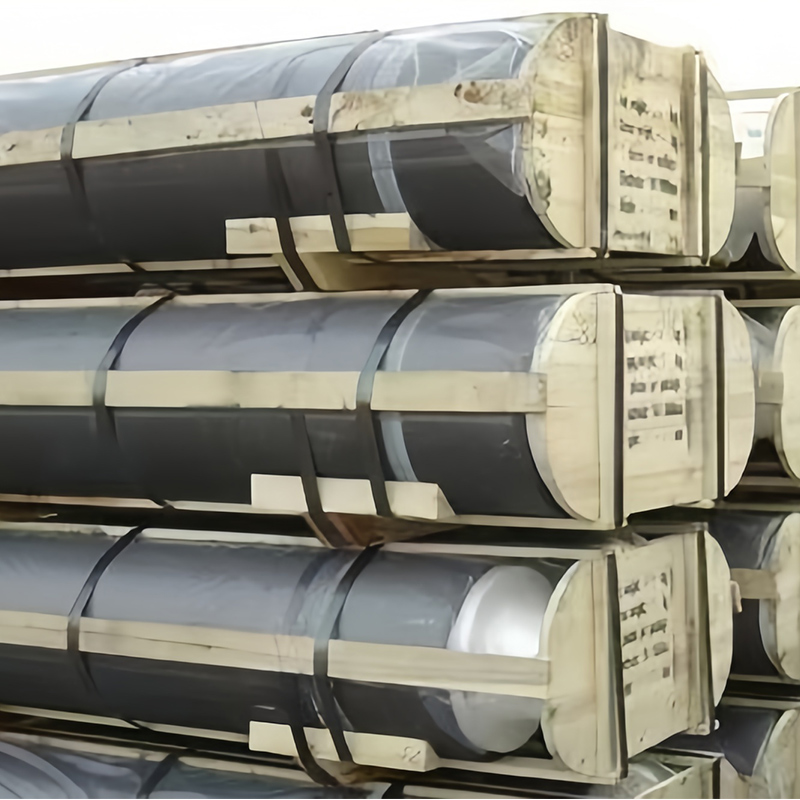

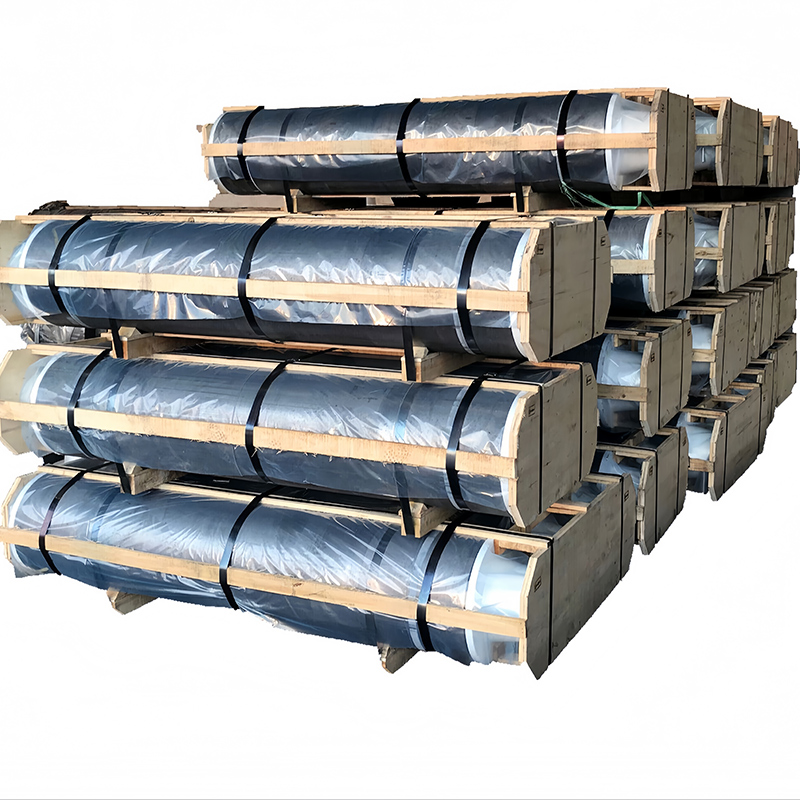

Semi-Graphitized Petroleum Coke (SGPC)

SGPC is widely used in EAF steelmaking, foundries, and electrode production as a cost-effective carburizer, enhancing melt quality and fitting RP electrode manufacturing and low conductivity applications.

Description

marker

Basic Description

Cost-Effective Carbon Additive for Graphite Electrodes and Metallurgical Applications

Semi-Graphitized Petroleum Coke (SGPC) is a cost-effective carbon material derived from low-sulfur petroleum coke through high-temperature calcination and partial graphitization. It typically features a fixed carbon content ≥98.5%, volatile matter ≤0.6%, and sulfur content ≤0.5%, making it an ideal recarburizer and conductive additive.

In the graphite electrode industry, SGPC serves as a key raw material or performance-cost balancing agent. It is especially used in the production of Regular Power (RP) graphite electrodes, where ultra-high conductivity is not critical. SGPC enhances the overall carbon content and contributes to the structural integrity of the green electrode during baking and final graphitization.

Key Technical Parameters

| Parameter | Typical Value |

| Fixed Carbon (FC) | ≥98.5% |

| Sulfur (S) | ≤0.5% |

| Volatile Matter | ≤0.6% |

| Moisture | ≤0.5% |

| Ash Content | ≤1.0% |

| Real Density | 2.03–2.10 g/cm³ |

| Particle Size | 0–1mm / 1–5mm / Custom |

Note: Specifications can be customized based on user requirements.

Advantages in Graphite Electrode Manufacturing

● Cost Reduction: Compared to fully graphitized petroleum coke (GPC), SGPC offers significant savings while maintaining sufficient conductivity for RP electrodes.

● Moderate Electrical Conductivity: Adequate for low- to medium-power EAF/LF applications, supporting stable arc performance.

● Improved Thermal Resistance: Partial graphitization improves thermal shock resistance and oxidation behavior during electrode operation.

● Good Processability: Excellent blending properties with needle coke and pitch ensure uniformity in extrusion and forming.

Industrial Applications

● Graphite Electrodes: Used in RP-grade electrode paste formulations to reduce cost and control resistivity.

● Recarburizer in Steelmaking: Common in induction furnaces and ladle metallurgy for efficient carbon recovery.

● Foundry Cast Iron Production: Offers low-sulfur, high-purity carbon for gray and ductile iron castings.

● Aluminum Smelting: Occasionally used in cathode and anode blocks due to its partial graphitized structure.

Why SGPC is Gaining Global Attention

With increasing pressure on raw material costs in the steel and non-ferrous metal industries, SGPC has emerged as a strategic alternative to high-cost needle coke and fully graphitized products. Its balanced performance and affordability make it especially attractive for manufacturers using Electric Arc Furnaces (EAF) and Submerged Arc Furnaces (SAF), where bulk carbon input and cost control are crucial.

Contact us now for detailed TDS, COA, pricing, or SGPC sample evaluation tailored to your graphite electrode or recarburizer application.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic