Zvigadzirwa

350m Uhp Graphite Electrode - Premium Ultra High Simba Simba mhinduro yeEAF Stbeelmakaking

Iyo 350mm UHP Graphite Electrode yakanakira esimbi-eaf Steelmaking, inogonesa kunyungudika kwekuputika uye kudhirowa nekusagadzikana ikozvino uye kuderera. Izvo zvakare zvakakodzera kuti unyore kunatswa uye yakakwirira-tembiricha ferroalloy uye isina-ferus mesimbi yekunyudza, kuvandudza chigadzirwa uye simbi kuchena.

Tsananguro

Marker

Chigadzirwa kuongorora

Iyo 350mm Ultra Yakakwirira Simba (UHP) Elefiti Electrode yakagadzirirwa yakanyanya Electrical Mamiriro Electric uye EAFS), Lad DAD FLARDS Yakagadzirwa kubva 100% premium petirleum-sindano coke uye ultra-low sulfur yekunyora (itstrouse yekudzvanywa), multrocuses yekudzvanywa), multrocuses bhiza, uye Ultra-yakakwira grapitization pamusoro pe800 ° C.

Precision Cnc michina inovimbisa zvakakwana tambo mapepa, uye yakakwana nipple yakakodzera, uye yakaderera yekudzvinyirira, inokonzerwa nekusagadzikana arc kuita, kudanana kwakakura, uye kushoma elektrode kushandiswa.

Technical Converations - 350mm Uhp electrode

| Paramende | Unit | Electrode | Nipple |

| Kuramba | μom · · | 4.8 ~ 5.8 | 3.4 ~ 4.0 |

| Kukotama Simba | MPA | ≥.0 | ≥ 22.0 |

| Elastic Modulus | GPA | ≤ 13.0 | ≤.0.0 |

| Bulk density | g / cm³ | 1.68 ~ 1.73 | 1.78 ~ 1.84 |

| Inowedzera yekuwedzera inoenderana | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| ASH Zvemukati | % | ≤ 0.2 | ≤ 0.2 |

| Inotenderwa ikozvino | A | - | 20000 ~ 30000 |

| Zvazvino | A / cm² | - | 20 ~ 30 |

| Chaiyo dhayamita | mm | Max: 358 min: 352 | - |

| Kureba chaiko (kunobatsira) | mm | 1600 - 2400 | - |

| Kureba kutsungirira | mm | ± 100 | - |

| Mutongi mupfupi urefu | mm | -275 | - |

Core maitiro ekufunga

●Ultra-yakakwira magetsi maitiro

Inotsigira nekukurumidza arc kutanga uye yakagadzikana zvazvino kuyerera munzvimbo dzakakwirira-dzinogona.

●Yakanakisa Thermal kuvhundutsa kupokana

Kuwedzera kwekunze kwekuwedzera kunoderedza kupaza panguva yekukurumidza tembiricha.

●Robugs Mechan Simba

Anosimudzira mashandisirwo ekushushikana panguva yekushanda, achiraira, uye kurira.

●Yakareba Zvemukati Zvinyorwa

Akaderedza ASH, Sarufa, uye kushamisika kunodzora kuumbwa uye nekuvandudza kwesimbi.

●Precision-Machine Nipples

CNC-Machineed tambo dzinove nechokwadi cheElectrode-nipple yakakodzera, kudzikisa kubatana kwekunyika uye kugadzirisa kunhuwirira.

Chiitiko Chekushandisa

●EAFARD EAF Steelmakaking

Yakanakisa yekunyungudutsa ichinyungudika uye yakaoma mune yakakura-kugona eafs, inopa nekukurumidza inonyungudika melcle uye yakakwira simba rekubudirira.

●Lale flath (lf) sekondari kunatswa

Inochengetedza tembiricha yekuzvishingisa uye inogumisa rexidation panguva yekufadzwa uye kusuwa.

●Ferroalloy kugadzirwa muSafs

Kupedza kuenderera mberi kwakanyanya-kupisa-tembiricha muSilicon-Manganese, Ferrochrome, uye Calcium Carbide Smollting.

●Yakanyanya-Pollity isiri-ferus Metallurgy

Inoshandiswa mukunyungudika aluminium, mhangura, uye titanium alloys uko kusvibiswa kwakaderera kwakakosha.

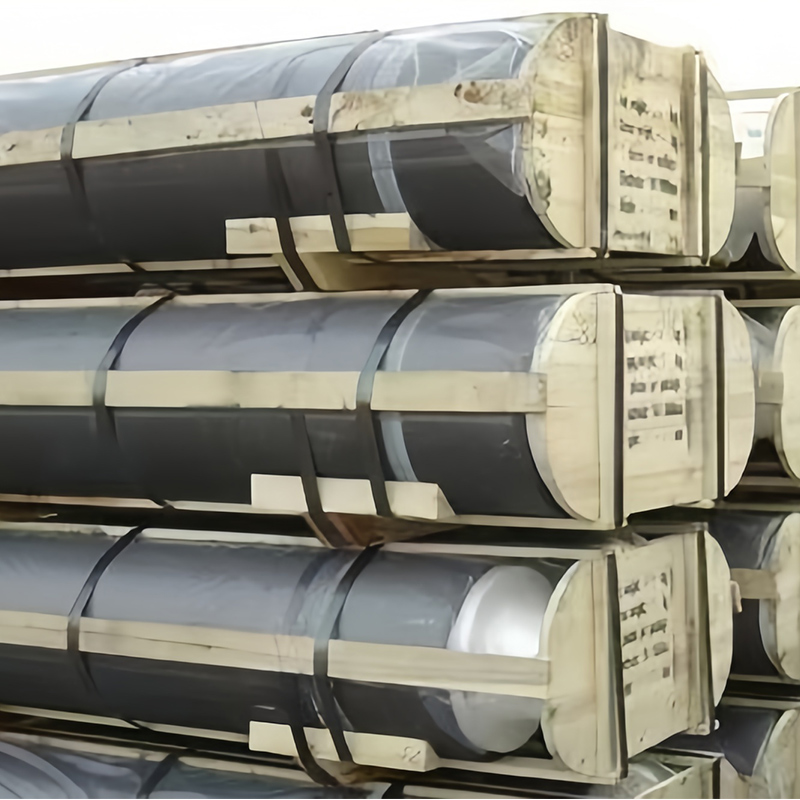

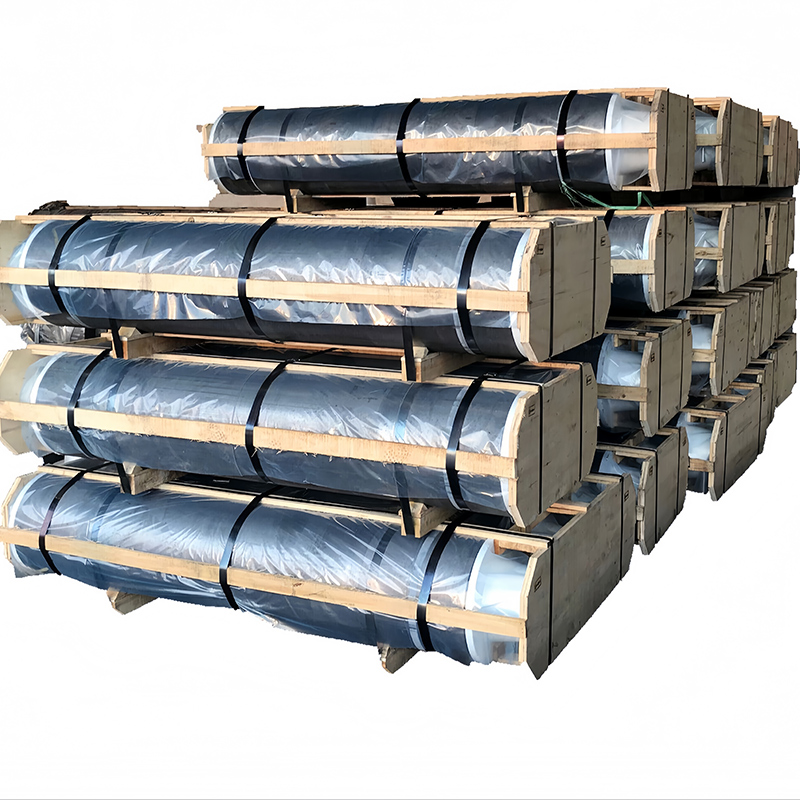

Kugadzira & Hwakasimbiswa Chivimbo

● Zvishandiso zvakawandisa:Premium sindano coke ine sarufa ± 0.03%, yakaderera ASH, uye yakaderera.

● Kugadzira & kubheka:Isoostatic / Extrussion kuumbwa, ichiteverwa neye akawanda-nhanho-nhanho inokwira kusvika ku900 ° C for ° Comedsional kugadzikana.

● Graphifization:Yakagadziriswa pa ≥ 28 ° C yeClemsally Crystalline alignment uye unitivity.

● CNC chaiyo yekunyora:Electrodes uye nipples yakakwirisa kune tight sholerces yekunyepedzera kushoma.

● Kuongorora zviyero:Kuenderana neASTM C1234, IEC 60239, GB / T 20067, uye pasi pekupedzisira, kuramba, uye nekuedzwa.

Kupera-Mushandisi Kubatsira

● Yakaderedzwa Electrode Installption Rate (ecr)

Yakakura density uye yakaderera porosity inoguma nekupfeka kushoma uye vashoma kutsiva.

● Yakavandudzwa kushanda nesimba

Kudzikira kudzikisa kupokana kunoita kuti nekukurumidza kunyungudutsa uye kuderedza simba (kWh / t) kushandiswa.

●Yakakwirira Steel Kuchena

Kusvibiswa kwakaderera kunoita kuti vazive zvidiki zvekusaderera uye vashoma vasingamoni masimbi.

●Hupenyu hweBasa Rakakura

Nguva refu inoshanda clecle uye yakaderedzwa nguva yekufamba kuburikidza neye mechanical durability.

Mhedziso

Iyo 350mm UHP graphite electrode electrode inopa chiyero chakakwana chekuita kwemagetsi, kutendeka kwemuchina, uye kusimba kwekuwedzera. Injiniya yekubudirira nekuvimbika, inoderedza mari yekushanda, uye inowedzera mhando yemukati, ichiita kuti ive sarudzo yazvino yeaaf uye lf mashandiro ezasi masimbi uye alloy zvigadzirwa zvivakwa.