Zvigadzirwa

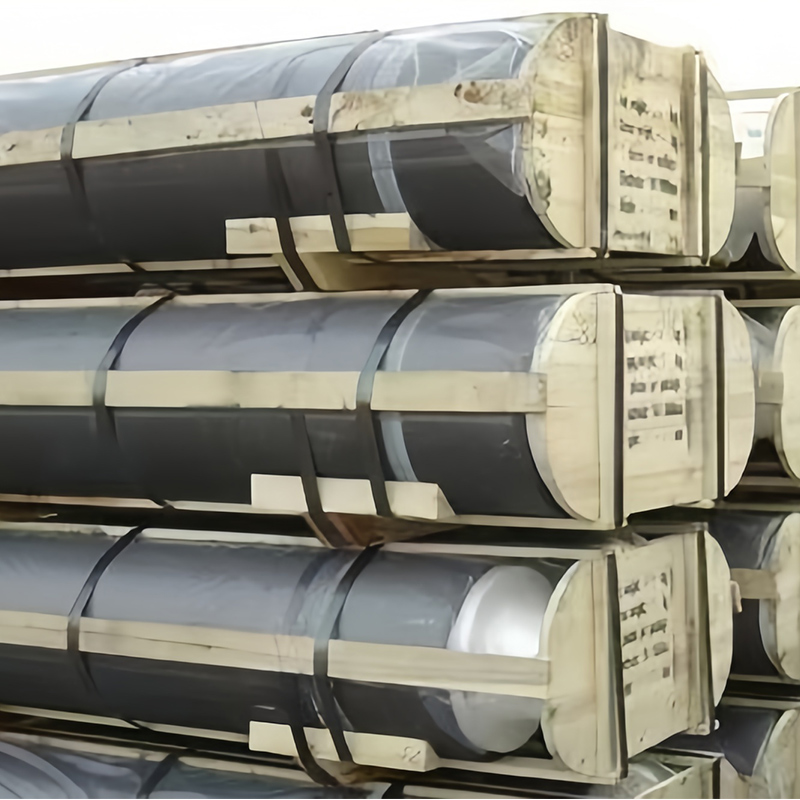

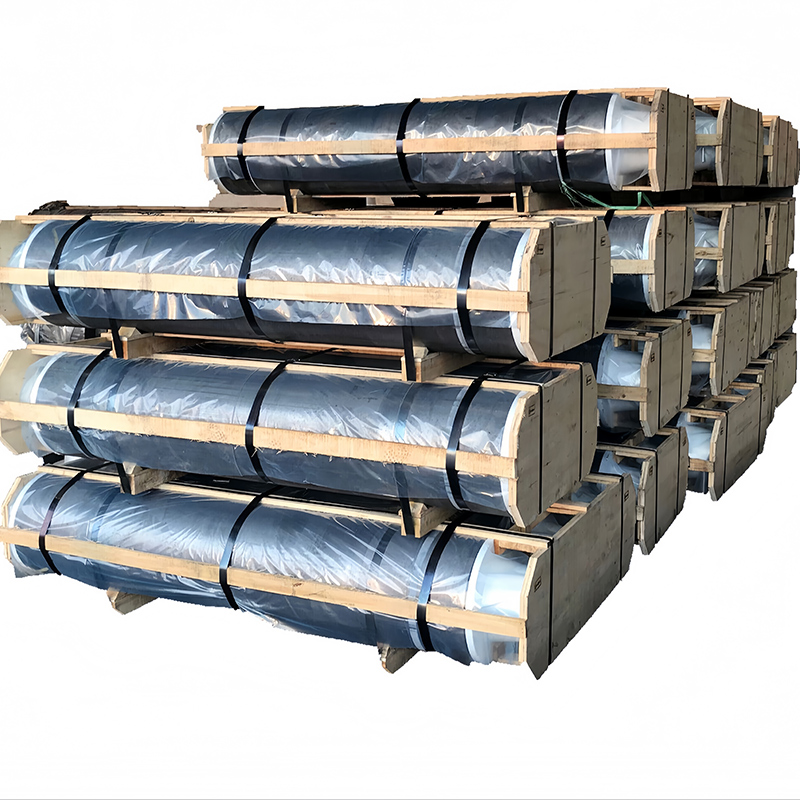

650 mm / 700 mm rp-giredhi grapite electrodes

Yakakwana yeiyo yakakura-eaf steelmaking, ladle inonatsa, uye ferroaly kugadzirwa. Inochengetedza Superior DeChion, Kugadzikana Kwekudzivirira, uye Simba reMuchina pasi peRound Formal Shock uye mutoro unorema.

Tsananguro

Marker

Tsananguro huru

RP (nguva dzose simba) giredhi reMagetsi eMajmita e650 mm uye 700 mm mainjiniya ekunyora magetsi arc Yakagadzirwa kubva premium tsono-coke Feedstock uye yakakwirira-mhando yemarata tarch, aya ma electrodes anopa chiyero chakakwana cheMagetsi, simba, uye kugadzikana kwekunyora. Kuburikidza nekunyora kwemakwikwi uye kwakasimba kudzora

Rp graphite electrode parameter - 650m & 700mm

| Chinhu | Unit | Electrode | Nipple |

| Kuramba | μom · · | 7.5 ~ 8.5 | 5.8 ~ 6.5 |

| Kukotama Simba | MPA | ≥ 8.5 | ≥ 16.0 |

| Elastic Modulus | GPA | ≤ 9.3 | ≤ 13.0 |

| Bulk density | g / cm³ | 1.55 ~ 1.63 | ≥ 1.74 |

| Inowedzera kuwedzera cte | 10⁻⁶ / ℃ | ≤ 2.4 | ≤ 2.0 |

| ASH Zvemukati | % | ≤ 0.3 | ≤ 0.3 |

| Inotenderwa ikozvino | A | - | 650mm: 34000-42000 700mm: 36000-46000 |

| Zvazvino | A / cm² | - | 650m: 12-14 700m: 11-13 |

| Chaiyo dhayamita | mm | 650: Max 663 min 659 700: Max 714 min 710 | - |

| Chaipo chaihwo | mm | 650: 2400 inobatsira 700: 2700 inobatsira | - |

| Kureba kutsungirira | mm | ± 100 | - |

| Pfupi pfupi | mm | 650: -300 | - |

Ongorora: Kukoshesa kunogona kusiyana zvishoma zvichienderana neiyo yekugadzira process uye dzimba dzekunyora.

Key maficha & mabhenefiti

●Magetsi akakwirira magetsi:

RP Electrodes inoratidzira yakaderera simba remagetsi basa, kuwedzera zvazvino kuendesa hunyanzvi uye yakagadzikana arc kuchengetedza panguva yeaf clecle.

●Simba repamusoro resimba:

Optimized Spural uye Inomanikidza Simba Rinoderedza njodzi pakubata, Welding, uye muchoto inoshanda, inowedzera yakazara electrode shandisa.

●Yunifomu yezviyo zvinhu:

Yepamberi Graphification process inoburitsa homogeneouscenture micrownure

●Yakareba yakareba kusvika mazinga:

Kudzora kwakasimba kweAsh, phosphorus, Sarufa, uye zvemukati zvemukati zvinoona kusvibiswa kwakadzikira, kuumbwa kwakadzika, uye kwakavandudzwa simbi / funroalloy mhando.

●Yakavandudzwa Inogadziriswa Kugadzikana:

Kuderera kwehuwandu hwekuwedzera kwekuwedzera kudzora madgegates kupaza pasi pekukurumidza tembiricha tembiricha, kuwedzera hupenyu hwebasa uye kuderedza kuputsa.

Zvishandiso

●Magetsi arc machira (EAF):

Epturary Electrodes ye Scap-yakavakirwa simbi uye Ferroaly Production.

●Ladle Firama (LF):

Inokodzera maitiro ekunatsa anoda high yekudzora.

●Yakanyudzwa Arc Zvivakwa (Saf):

Inogona kugadziriswa kune mamwe mashandiro eSilicon muSilicon, phosphorous, uye mamwe maindasitiri ezvematanda, kunyangwe kazhinji maindasitiri eRP anofarirwa eaf.

●Faces & Isiri-Ferrousy inonyungudutsa:

Inoshandiswa mumanyoreredzo ekunyungudika uko inoenderana arc kugadzikana uye kuderera kwekusachena kwekutenderera kwakanyanya.

Hunhu hwekusimbisa & maitiro ekugadzira

●Raw zvinyorwa zvinosarudzwa:

Yakakwira-giredhi sindano coke ine mashoma madiki exlatile nyaya pazasi 0,6% yakasarudzwa kuti ideredze porosity.

●Briquetting & Baking:

Yunifomu inosanganisa neyekutanga marasha emarata tarch tarch binder, ichiteverwa neiyo isoostatic kupikwa, kunoita kuti dent. Inodzorwa kubheka muTunnel inofutira kuma 800-900 ° CRours Volates zvishoma nezvishoma.

●Graphifization:

Yakakwira-tembiricha yakakura

●ChaCecision mechining:

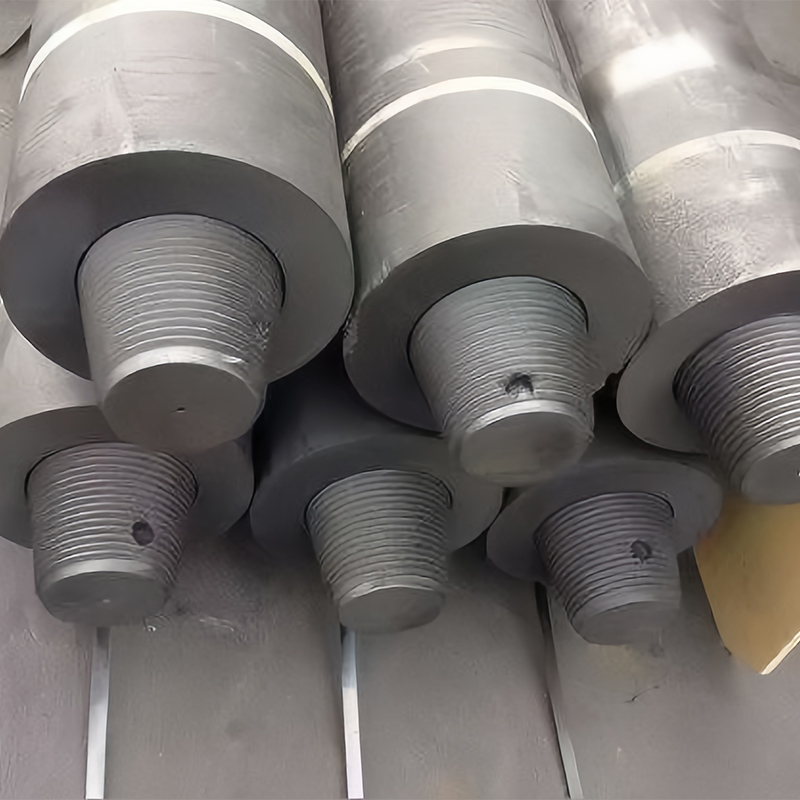

CNC Lathes inowana yakasimba diameter tolerances (± 2 mm) uye tambo dzakatarwa kuti dzivimbise hwakakwana hwakakwana uye hushoma remagetsi kurwisa majoini.

●Kuongorora & Kuedzwa:

Imwe neimwe yemagetsi iri mupeperts ultrasika

Chaizvoizvo Mutengi Anobatsira

●Lower electrode yekushandisa chiyero (ecr):

Optimigizekisikopedza simba uye density kuderedza mabheti ekupenga, kuchengetedza mari yekutsiva electrodes.

●Yakaderedzwa yemagetsi simba rekushandisa:

Yakavandudzwa Discover uye Arc Kugadzikana kududzira kuShure Kwh pa toni yesimbi.

●Hupenyu hwekuwedzera Webasa:

Yakavandudzwa mechaniki uye inopisa zvivakwa zvinodzikira kuputswa uye nguva.

●Inowirirana Chigadzirwa mhando:

Yakareba isina kusvibiswa mazinga anoona yakanyanya-yekuchenesa simbi uye alloy kubuda, musangano unomarara metallurgical yakatarwa.

Yakawedzerwa Technical Conitial

RP-giredhi magetsi anozivikanwa zvakanyanya kune yavo-performance yekuita muEAF EAF Oisting. Kuenzaniswa neHP (Simba rakakwirira) mamakisi, rp electrodes kazhinji inoratidzika zvishoma kupokana kwepamusoro uye kuderedza density; Nekudaro, ivo vanoramba vari sarudzo dzehupfumi zvakanyanya kune dzakajairwa maitiro ekunyungudika. Chimiro chavo chezviyo-chinoratidzwa neyekwende, chemagralline graphite madhiri-inoderedza huwandu hwemiganhu yezviyo, nekuvandudza magetsi maitiro.

Muzvikamu zvikuru zveSimbi, Electrode Diameter Sarudzo (650 mm vs. Mm) Hinges pane Chira Shandura Shandura Simba, uye inoda simba rekunyungudza, uye kupera-kwehupenyu-yehupenyu tsvimbo kureba kwekufungidzira. Nekutsvagisa iyo r-kukosha (kudzivisa / density ratio) kusvika ≥ 0,92, idzi rp electrodes dzinoratidza mukana wekuparadza kuwanda kwekushambadzira panguva yechiravira.

Iyo yakaderera ASH Zvinyorwa uye yakadzorerwa isina kukodzera svutugadzike kuti zvinhu zvinyungudutswa zvakachengetedzwa kusvika kune mhedziso simbi (i.ege, Ultra-yakaderera phosphorus, sulfu, uye oksijeni). Munguva yeTalding yeThe Electrode Rods uye nipples, iyo yekuchina yekuchina yetambo yakakosha kuchengetedza yunifomu kuyerera kwazvino kuyerera.

Kubata kwakakodzera protocol-sekuratidzira muchoto uye nekudzora kutonhora-kubatsirwa kudzivirira kuparara kwemaza. Mazhinji emazuva ano kupisa-kupesana giredhi eafs anosanganisira zvakare kutonhora uye mune-cheve-cheve electrode chinzvimbo manejimendi kuti uwedzere kushandisa tsvimbo.

Mhedziso

650 mm uye 700 mm RP-Giredhiti graphite electrodes inopa mhinduro ine mwero kune steelmakers kutsvaga mutengo-kushanda, zvakavimbika kuita. Nesimba remagetsi emagetsi uye nemuchina, aya electrodes inotsigira yakagadzikana arc maitiro, yakadzika simba rekushandisa, uye kusvibiswa kushoma kwesimbi yakanyungudutswa. Nekutamisa maitiro emhando yepamusoro uye nekupa zviyero zvekugadzirisa, ivo vanosangana zvakasiyana-siyana mashandiro ekushandisa-kubva kune imwe chete-shefer eafs kusvika kune yakakura-chiyero mitezo mizhinji-tap. Kunyangwe kushomeka kwemagetsi idzva idzva