Zvigadzirwa

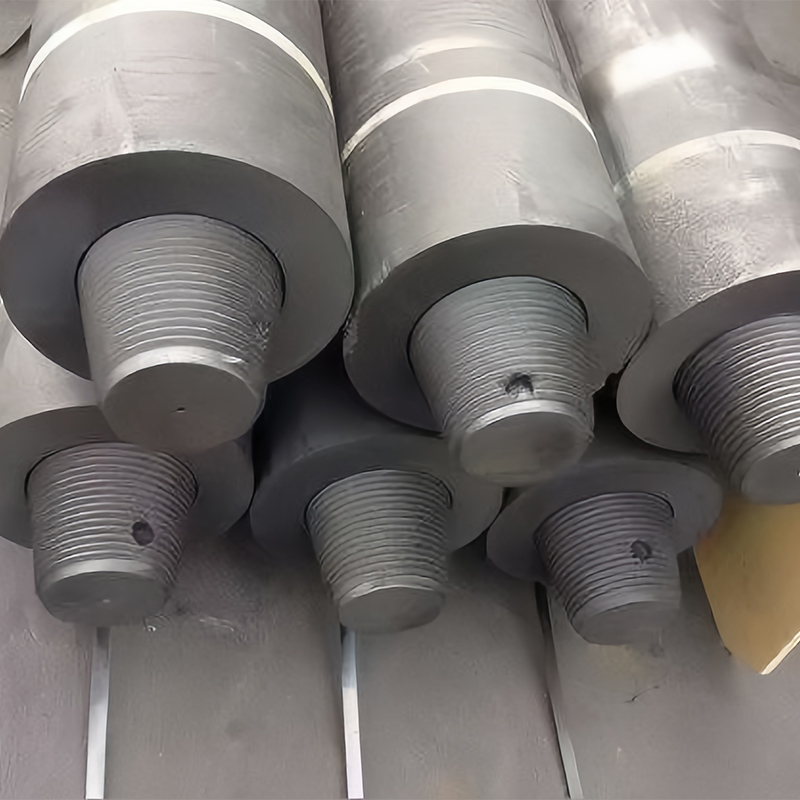

Kuiswa kwezvinhu zvegirisheni kune electrodes uye yakakwira-tembiricha application

Zvigadzirwa zveGraphite zvinoshandiswa zvakanyanya muSemiconductor Minda, Aerospace Nozzles, Arc Fursentile Electrodes, uye magetsi emakemikari. Inoratidzira Ultra-Yakanyanya Kuchena, kupokana kwakanyanya, uye kupokana kwakaderera kwemagetsi, vanoshanda sezvinhu zvakakosha muindasitiri vekare uye maindasitiri emagetsi ekugadzira.

Tsananguro

Marker

Chigadzirwa kuongorora

Graphite zvigadzirwa zvakakamurwa zvakavakirwa pane nzira dzekugadzira, saizi yeGira, yakachena huwandu, uye density. Mhando nhanhatu dzemapururu emifananidzo inoratidzwa pazasi inoshandiswa zvakanyanya muGraphite Electrode kugadzirwa, Edm (Semiconductor Ferming Minda, uye yakakwira metallurgy, kusangana neyunivhesiti yekuita maindasitiri.

1. Isoostatic graphite

Yakagadzirwa kuburikidza neyunifomu isosticum inotsvina, iyi graphite inopa isotropic chimiro ne:

● Yakakura yakawanda density uye compact micranture

● Kuderera kwemagetsi kupokana uye kunhuhwirira kwakanaka

● Yakanyanya kufambidzana

● Kunze kweLealidation Kudzikisira uye inodzivirira kupokana

Chaizvoizvo Zvikumbiro:Edm Electrodes, Croctibles yeSolar Indasitiri, Semiconductor Kupisa Zvinhu, Kupisa Kunodzvanywa Kuumbwa kweVanyori veAerospace.

2. Yakanyanya kuchenesa yakaumbwa graphite

Iine Ultra-yakaderera ASH Zvinyorwa (<50 PPM) uye carbon kuchena ≥99.99%, yakanakira:

● Ultra-yakachena vacuum kana inert gasi nharaunda

● Semiconductor uye Appavoc application inotsvaga kusvibiswa kwesimbi

● Yakakwira-tembiricha inotsikidzo uye yakachenesa yekurayira michina

3. Zvakanaka zviyo zvakakwirira simba graph

Neavhareji yezasi saizi ≤10 μm μm, izvi zvinopa zvinhu:

● Zvakanakisa zvinoshanduka uye zvine simba simba

● Yakanyanya kuchikorochechechechechechekeresa uye kupedzisa pamusoro

● Kugona kufambisa zvikamu zvakaoma-zvakavezwa

Zvishandiso:Edm electrodes, magetsi maumbi, kunyatsogadzira zvishandiso.

4. General-chinangwa chakaumbwa graphite

Mutengo-unobudirira uye wakasimba mukuita kwepanyama:

● Pakati pesimba uye inobata

● Zviri nyore muchina

● Wide Rwiyo rwekushanda kwemaindasitiri

Zvishandiso:Ruvhuru dzemoto, zvikamu zvemunda zvemunda, kabhoni mashanga, graphite liners.

5. Pakati-coarse zviyo graph

Nesike yeGrough inotanga kubva pa0,8-1.5 mm, inopa:

● Kuramba kwakasimba kusimba kwekushamisika

● Dimensional kugadzikana panguva yekudziya tembiricha

Zvishandiso:Electrode zvigadziko, zvemaindasitiri chemuchoto chengetedza zvivakwa, metallurgical molds.

6. Great zviyo graphite graphite

Size inoonekwa

● Kukurumidza kupisa kunoitwa uye kwakanaka thermal kugadzikana

● Yakanakira kune HERSH ANOGONESA ZVINONYANYA uye Zvinorema-Basa Zvikumbiro

Zvishandiso:Simbi yekukanda Mold

Chaizvoizvo technical parameter

| Paramende | Kukosha Range |

| Bulk density | 1.60-1.85 G / CM³ |

| Simba rekumanikidza | 40-90 MPA |

| Basa remagetsi | 8-15 μω · |

| Inobata | 80-160 w / m · k |

| ASH Zvemukati | ≤0.1% (yakanyanya kuchena <50 ppm) |

| Avhareji yeiyo size | ≤10 μM to> 2 mm |

| Max anoshanda temp | ≤3000 ° C (muInert Mhepo) |

Zvese paramita maitiro akajairwa, akaedzwa paASTM / ISO zviyero.

Pfupiso

Kubva pane zvakanaka-zviyo zviso zveSoostatic graph kune coarse-zviyo zvinokanda zvidhinha, giredhi rega rega reMafiriti inoshandisa maindasitiri chaiwo uye einjiniya zvinodiwa. Isu tinopa tsika yemachina masevhisi zvichienderana nemutengi wemutengi, ine sarudzo dzinochinja-chinja saizi, kuchena, uye density. Zvishandiso zvedu graph kushandiswa zvinoshandiswa zvakanyanya muEdm Electrode fani, Semiconductor Thermal Systems, Solar inotadza kuronga, uye metalurical yekugadzirisa michina, ichisimbisa kugadzikana kwenguva refu uye kuita.

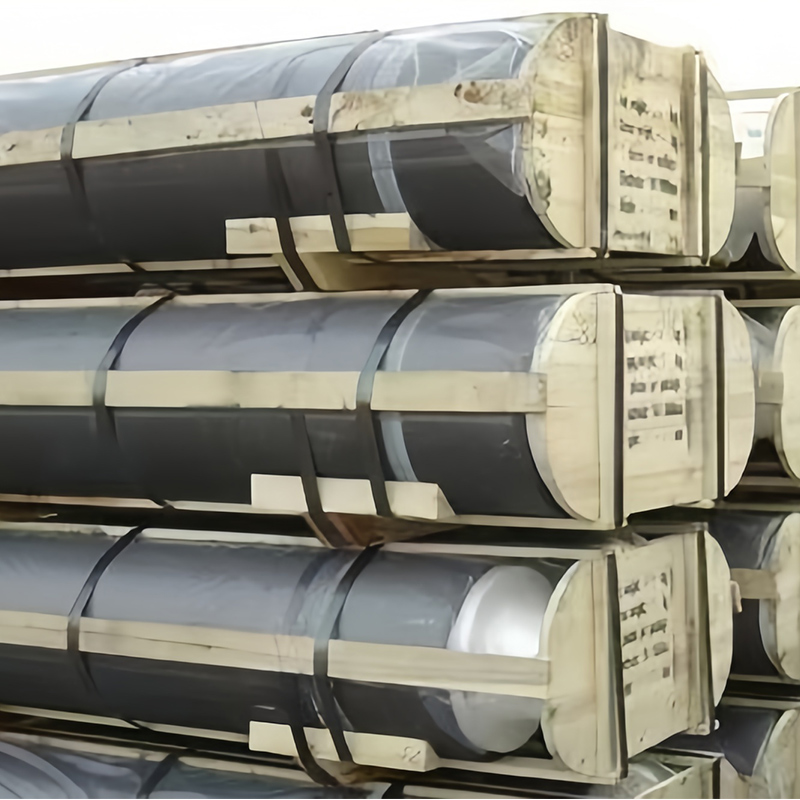

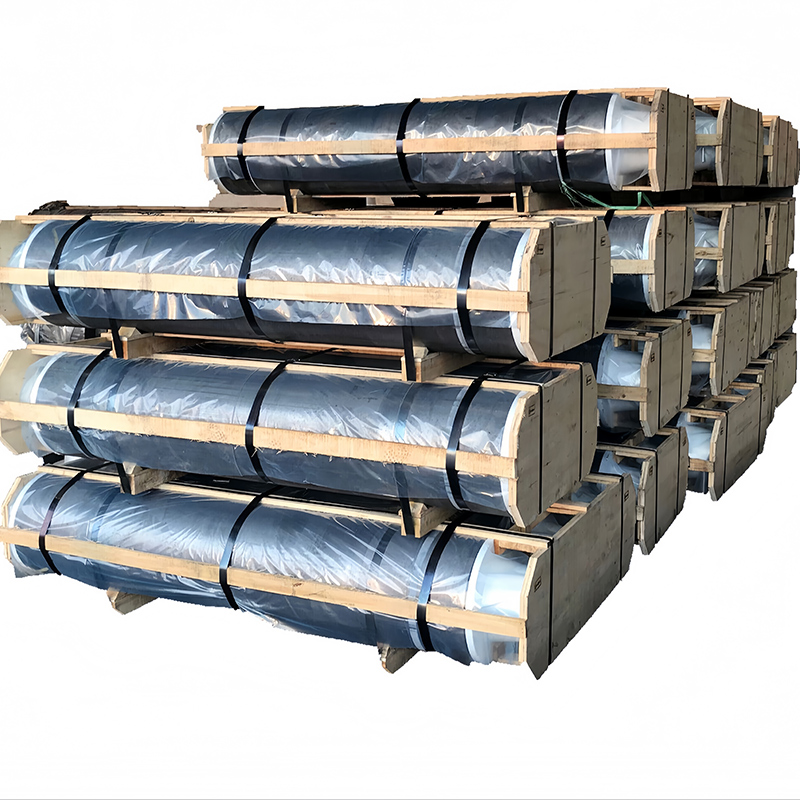

Tsika graphite mahwendefa uye zvinhu zvakanyatsowanikwa pane kukumbira. Cnc machining uye yakanyanya-yekuchena kurapwa inotsigirwa. Inokodzera nzvimbo dzose dzakanyanyisa-tembiricha.