Lihlahisoa

400MM UHP Graphite Electtrode - E tsoetseng pele ea tharollo ea matla a tšepe

Sesebelisoa sa 400mm UHP sa graphite se enjene ea li-gulight tse boima (LF), li-turnaces tse boima E fana ka pherekano e phahameng le ho tsitsipana ho qhibilihang, ho fokolisa tšebeliso e potlakileng ea elektrode, mme e ile ea ntlafatsa boleng ba tšepe e ntlafalitsoeng le tlhahiso ea lihlahisoa tse tsoetseng pele le ea anyesang.

Tlhaloso

lerker

Tlhatlhobo ea sehlahisoa

Li-400m tsa UHMP (Ultra e phahame haholo) E entsoe ho sebelisa sekholopane sa marang-rang sa Premium Sole Precination Mechini ea Cnc e netefatsa ho nepahala ha sebopeho le khoele e ntlafalitsoeng, e netefatsoang e tsoileng matsoho e phahameng le khanyetso e fokolang ea morao.

E etselitsoe ho mamella manonyeletso a hona joale, 400mm UHP e tlatlapa motlakase o motle oa motlakase, o phahameng ka holimo ho hamafatso e phahameng haholo, le matla a maholo a matla. Sekhahla sa eona se fokolang le ts'ebetso e sa fetoheng e etsa hore ho be bonolo hore e be ea bohlokoa hore e sebetse hantle bakeng sa matla a matla a matla a matla a tšepe a tšepe.

Litlhaloso tsa bohlokoa tsa theknoloji (400mm UHP elertrode)

| Paramente | Yuniti | Electrode | Nipple |

| TLHOKOMELISO | μω μ | 4.8 ~ 5.8 | 3.4 ~ 4.0 |

| Matla a hoba | Mpa | ≥ 12.0 | ≥ 22.0 |

| Elastic Modulus | GPA | ≤ 13.0 | ≤ 18.0 |

| Bolulo bo bongata | g / cm³ | 1.68 ~ 1.73 | 1.78 ~ 1.84 |

| Foreha | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Likahare tsa molora | % | ≤ 0.2 | ≤ 0.2 |

| E lumelle ea hajoale | A | - | 25000 ~ 40000 |

| Bonolo ba hona joale | A / cm² | - | 7 ~ 24 |

| Bophara ba 'nete | mm | Max: 409 mets: 403 | - |

| Bolelele ba 'nete (boakana) | mm | 1800 - 2400 | - |

| Ho mamella ho mamella | mm | 100 100 | - |

| Bolelele ba 'musi ba bokhutšoanyane | mm | -275 | - |

Melemo ea Ts'ebetso

● Ho putlama ha boitšoaro ba motlakase bo phahameng ba matla 'mele bo nolofalletsang ho fetisoa, ho fokotsa ts'ebeliso ea matla nakong ea ho qhibiliha.

● Har'a ho makala ha molumo, ho fokotsa ho hlakisa le ho holisa bophelo ba motlakase tlas'a khatello ea mocheso khafetsa.

● Ke matla a ka ho fetelletseng ka ho tšoarella ho matlafatsang nakong ea ts'ebetso le sebopeho sa mollo.

● Metheong e tlase ea ho se hloeke ka tlase, sebabole, sebabole, le taba e sa tsotelleng ho ntlafatsa bohloeki ba tšepe bo foufalitsoeng mme ba fokotsa sebopeho sa spag.

● Methapo ea cnc e nepahetseng e netefatsa khokahano e tiileng ea motlakase ea motlakase e matla bakeng sa botsitso ba ho tsitsipana.

Maemo a Kopo

●Motlatso oa motlakase oa Arc (oaf) Steelmaking:E ntlafalitsoe bakeng sa crac ea matla a phahameng le ka kotloloho ea tšepe (DRIP) e qhibilihang, e ts'ehetsa likokoana-hloko tsa hona joale tsa ho qhibiliha ha hona joale.

●Ladle tubnace (lf) ea bobeli e ntlafatse:E fana ka taolo ea mocheso o nepahetseng mme e fokotsa botsitso nakong ea lits'ebetso tsa bobeli tsa metalgary bakeng sa ho onyesa le tlhahiso e se nang letsoai.

●Phello e kenelletseng ea ArcE loketseng tlhoko e phahameng ea mafura e phahameng joalo ka Ferrochrome, silicon manganese, le calcium carbide e tsitsitseng.

●Metsotso e sa foleng ea tšepe:E loketseng koporo, aluminium, titanium le a mang a ikhethang a khethollang taolo le taolo ea litšila le bohloeki li mpefatsa.

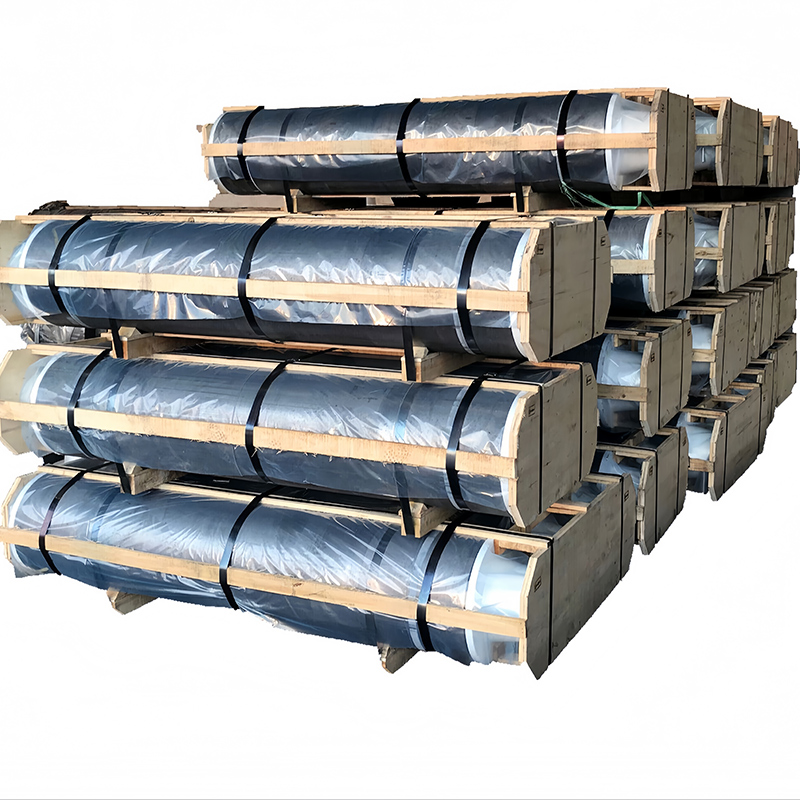

TLHOKOMELISO EA HO FIHLA

● E entsoe u sebelisa Coke ea Nale ea Nale ea Nale ea Nale ea Nale ea Nale ea Nale ea Sulfur Civisher

● Lits'oants'o tse kholo tsa khatello ea maikutlo le khatello ea khatello ea maikutlo le mela e mengata e qala ho fihlela ho 900 ° C bakeng sa letsoalo le nepahetseng le bohato bo boholo.

● Ho etsa litšoantšo tse phahameng tsa ultra - ho hlahisa setšoantšo sa li-crys

● Mechini e u thusang (3tpi / 4tpi / m72) e tiisa pele ho elektrose-nipple ho hanyetsa.

● Teko e thata le ho latela ASTM C1234, litekanyetso tsa GB / TT 20067 Liteko tsa Matla a Khopo.

Melemo ea mosebelisi ea FEELA

● Sebopeho se botenya, sebopeho se tlase se fokotsa ts'ebeliso ea motlakase ebe litšenyehelo tsa ts'ebetso li sebetsa haholo.

● Moetlo oa motlakase o moholo oa ho qhibiliha, o fokotsa ts'ebeliso ea matla ho ton ea tšepe e hlahisoang.

● Maiteko a tlase a ho tlisa ho kenya letsoho ho hloekisang seqhetsoana se hlahang se nang le likhakanyo tse fokolang le boleng bo ntlafalitsoeng ba alloy.

● Ho hloka kutloano ho phahameng le mochinichini o kenya bophelo ba motlakase, ho fokotsa boea ba boea ba boea le khafetsa.

Sephetho

Tlhatlhobo ea 400mm UHP e emela pictade e emela ntho e matla ea boloi ba graphicha e kholo libakeng tse thata haholo tsa metaltgical. Melemo ea eona e ikhethang, e futhumatsang le ea mecha e netefatsa ts'ebetso e nepahetseng, e fokotsoang hape, e e etsa lijalo tse tsoetseng pele le limela tsa tlhahiso.