Lihlahisoa

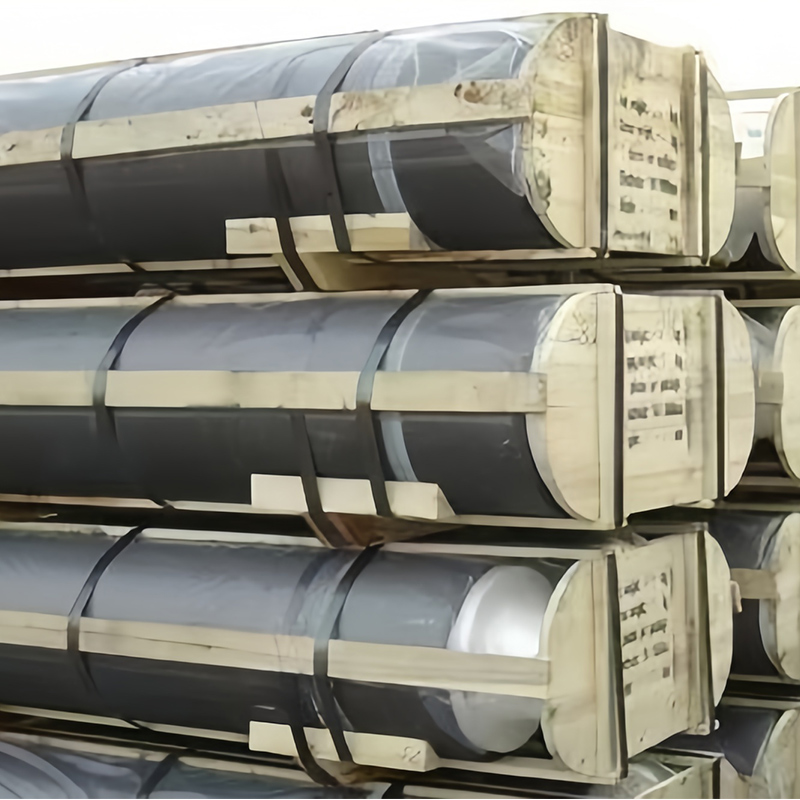

450mm UHP Graphite Electrode Threesview

450mm ultra matla a phahameng (uhp) graphite electrode e sebelisoa haholo ho elekse e kholo, le ladalligy. E theola boitšoaro bo botle ba motlakase, ho hana ho senya meno le matla a ho ntlafatsa tšebetso ea boruti le boleng ba tšepe.

Tlhaloso

lerker

Tlhaloso ea mantlha

Li-450m ultra matla a phahameng (uhp) graphite electrode e sebelisoa haholo ho eleksente ea motlakase ea motlakase le tse ling tsa mocheso o phahameng. E entsoe ho tsoa ho Coke ea Petimium ea Petimium ea Peke ea Petimium In Beke

Litlhaloso tsa bohlokoa tsa theknoloji

| Paramente | Yuniti | Electrode | Nipple |

| TLHOKOMELISO | μω μ | 4.5 ~ 5.6 | 3.4 ~ 3.8 |

| Matla a hoba | Mpa | ≥ 12.0 | ≥ 22.0 |

| Elastic Modulus | GPA | ≤ 13.0 | ≤ 18.0 |

| Bolulo bo bongata | g / cm³ | 1.68 ~ 1.72 | 1.78 ~ 1.84 |

| Foreha | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Likahare tsa molora | % | ≤ 0.2 | ≤ 0.2 |

| E lumelle ea hajoale | A | - | 32000 ~ 45000 |

| Bonolo ba hona joale | A / cm² | - | 19 ~ 27 27 |

| Bophara ba 'nete | mm | Max: 460 min: 454 | - |

| Bolelele ba 'nete (boakana) | mm | 1800 - 2400 | - |

| Ho mamella ho mamella | mm | 100 100 | - |

| Bolelele ba 'musi ba bokhutšoanyane | mm | -275 | - |

Ts'ebetso ea Tlhahiso

●Lisebelisoa tse so fetoloe:Coke ea Nale ea Nale ea Nale ea Nale ea Nale ea Nale ea Nale (<0.03%) ho netefatsa bohloeki bo phahameng le boitšoaro bo phahameng.

●Ho theha:Isostatic ha a hatelloa ke letsoalo le tšoanang le botšepehi bo tšepahalang.

●Ho baka:Karolo e mengata ea ho baka ho fihlela ~ 900 à C ho ntlafatsa matla le ho tlama.

●Tšoara:Phekolo e kaholimo ho 2800 ° C ho hlahisa setšoantšo sa boleng bo phahameng ka boitšoaro bo phahameng le bokooa ba futhumatsang.

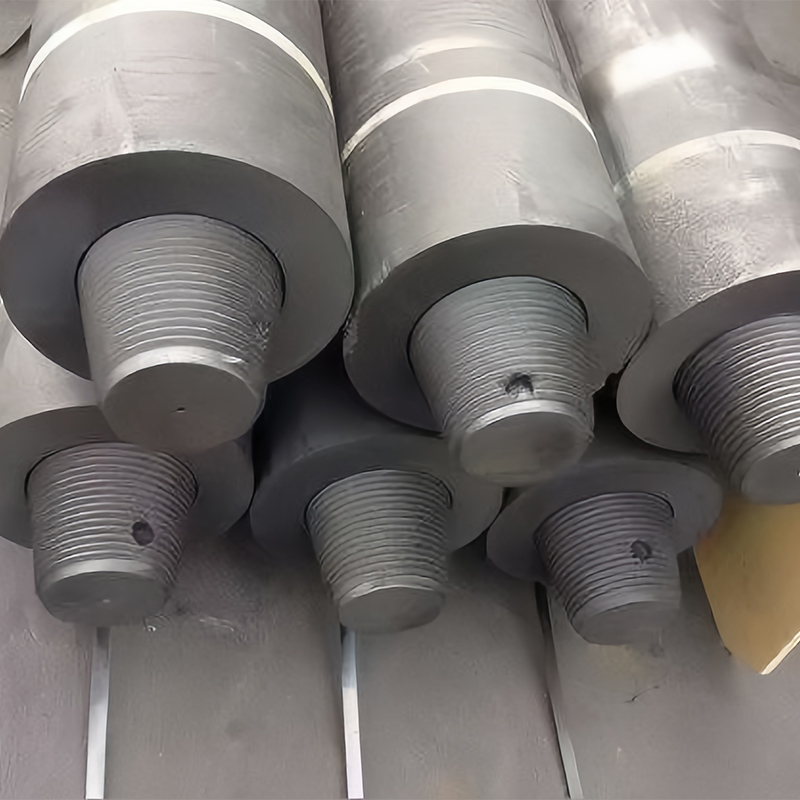

●Ho na le mochini:Sepheo sa Con ho na le masholu le likhakanyo tse matla tse tlatsang khokahano e sireletsehileng.

Likopo

●Setei sa motlakase sa Arc (EAF):Lillo tsa mantlha tsa ho qhibiliha ho qhibiliha le tšepe e fokotsehileng (DUGED), e fanang ka li-arcs tse tsitsitseng le tsa matla a matla.

●Ladle tubnace (lf) le akgn oksijene oksijene ea okgon oksijene (aod) li fifala:Li-electrode bakeng sa taolo ea mocheso le e nepahetseng e nepahetseng.

●Metal Rightlurgy:Melting and refining of copper, aluminum, nickel, and specialty alloys requiring high purity.

●Indiana sa lik'hemik'hale:E sebelisoa ka matla a mocheso o phahameng le tlhahisong ea silicon, calcium carbide le lik'hemik'hale tse ling tse thehiloeng ho Carbon.

Melemo

●Boitšoaro bo phahameng ba motlakase:Fokotsa tahlehelo ea matla le ho fokotsa tšebeliso ea matla.

●Khanyetso e Ntle ea Formal Shock:E thibela ho bola, ho holisa bophelo ba ts'ebeletso ea motlakase.

●Thepa ea Mechajinity:Matla a mangata a maholo le mafura a elatulus ha a nke khatello ea maikutlo.

●Litaba tse tlase tse tlase:E ntlafatsa boleng ba tšepe ka ho fokotsa litšila.

●Li-nipples tsa cnc tse nang le li-cncHo etsa hore likhokahano tsa motlakase li tiile, tse tlase tsa motlakase le ts'ebetso e tsitsitseng ea Arc.

Sephetho

Li-450m tsa uhm tsa uptrode tsa motlakase li lumellana le maemo a eona a nang le mochine ka mokhoa o nepahetseng oa motlakase oa motlakase, a futhumatsang le tšebetso. Sena se etsa hore e be karolo ea bohlokoa ea ts'ebetso e sebetsang le e tsitsitseng ka tšebetso ea kajeno ea ho kena-kenana le lits'ebetso tsa tšepe.