Lihlahisoa

Khethollo ea lisebelisoa tsa graphite bakeng sa li-electrodes le lits'ebetso tsa mocheso o phahameng

Lihlahisoa tsa Graphing li sebelisoa haholo masimong a tšoelesa ea semiconductor. Eba ea nang le bohloeki bo phahameng, ho hanyetsa khanyetso e khaphatsehang, le ho sebelisa lisebelisoa tse tlase tsa motlakase, ba sebetsa e le lisebelisoa tsa mantlha tsa tlhophisong tsa matla le matla.

Tlhaloso

lerker

Tlhatlhobo ea sehlahisoa

Lisebelisoa tsa Graphie li arotsoe ho latela mekhoa ea ho theha, boholo ba lijo-thollo, maemo a iqapetiki le letsoalo. Mefuta e tšeletseng ea lithibelo tse tsamaeang e bontšitsoeng ka tlase e sebelisoa haholo tlhahisong ea motlakase, edm (e sebelisa mekhoa ea motlakase, e leng sericouctor estics.

1.

Hlahisoa ka ho hatelloa ha unifond ho hatella, graphite ena e fana ka sebopeho sa isole ka:

● Bongata bo phahameng ba bongata le likokoana-hloko tse kopanetsoeng

● Ho hana ka motlakase le boitšoaro bo botle

● Ho kenella ho phahameng haholo

● Ho hanyetsa khetho e ntle le oxidation le ho tsitsipana le bothata

Litšitiso tse tloaelehileng:Metsoako ea Edm Elekberters, e hatellang indasteri ea letsatsi, semicondctor Heating, hlobo e chesang ea linonyana tsa Aerospace.

2. Boitšoaro bo phahameng bo phahameng bo qapiloeng

Ka li-conte ea ultra-e tlase ea molora (<50 ppm) le carbon purity ≥99.99, e loketse:

● Ho utsoa libaka tse sa lokelang kapa tse hloekileng

● Semiconductor le likopo tsa PhotoVoltaic li nahanne ka litlolo tsa tšepe tsa tšepe

● Ho tšenyo ea mocheso le sesepa se phahameng le seripi se seholo

3. Grain Grand graphite e matla

Ka boholo ba karolelano ea karolelano ≤10 μm, lintho tsena li fana ka maikutlo:

● Matla a matle a teteaneng le a hatellang

● Ho ikoetlisa ho phahama ha ho sebetsa le ho qeta

● Matla a ho etsa likarolo tse rarahaneng ka thata

Likopo:Edm Electrodes, hlobo ea elektroniki, preecuis e theha lisebelisoa.

4. Kakaretso ea graph e bopehileng

E theko e boima le e tsitsitseng ka ts'ebetso ea 'mele:

● Litsi tsa bo-boholo bo bohareng le boits'oaro bo futhumetseng

● Ho bonolo ho mochine

● Ho hlophisa lintho tse ngata tsa indasteri

Likopo:Li-linece line, likarolo tse futhumetseng tsa masimo, khabone ea khabone, linera tse khabisitsoeng.

5. Grain ea grani ea mahareng e bohareng

Ka boholo ba lijo-thollo bo tloha ho inging ho tloha ho 0.8-1,5 mm, e fana ka eona:

● Ho hanyetsa matla ho makala a futhumatsang

● Ho tsitsipana ka mokhoa o tsitsitseng nakong ea mocheso o matla

Likopo:Metheo ea electrode, Fubnace ea Boitsebiso ba Liindasteri, hlobo ea metaltargcal hlobo.

6. Grand graphite e kholo

Boholo ba lijo-thollo tse bonahalang> 2 mm, e loketseng mojaro o tukang o tukang le likopo tse phefumolohang:

● Khoeli ea mocheso e potlakileng le ho tsitsa hantle ha futhumatsang

● E loketseng libaka tse thata tsa ho hema le likopo tse boima

Likopo:Tšepe ea tšepe ea lahlela hlobo, bottoms baleform, litlolo tsa litheko tsa Converter

Li-paramente tse tloaelehileng tsa tekheniki

| Paramente | Boleng ba boleng |

| Bolulo bo bongata | 1.60-1.85 g / cm³ |

| Matla a hatellang | 40-90 MPA |

| TLHOKOMELISO E MOLEMO | 8-15 μω μ. |

| Ho Sebelisana le Pherekano | 80-160 w / m · h |

| Likahare tsa molora | ≤0.1% (bohloeki bo phahameng <50 ppm) |

| Boholo ba lijo-thollo | ≤10 μm ho> 2 mm |

| Sekhahla sa ho sebetsa | ≤3000 ° C (ka sepakapaka se maemong a leholimo) |

Lirapa tsohle ke litekanyetso tse tloaelehileng, e lekiloeng ka melao ea ASTM / ISO.

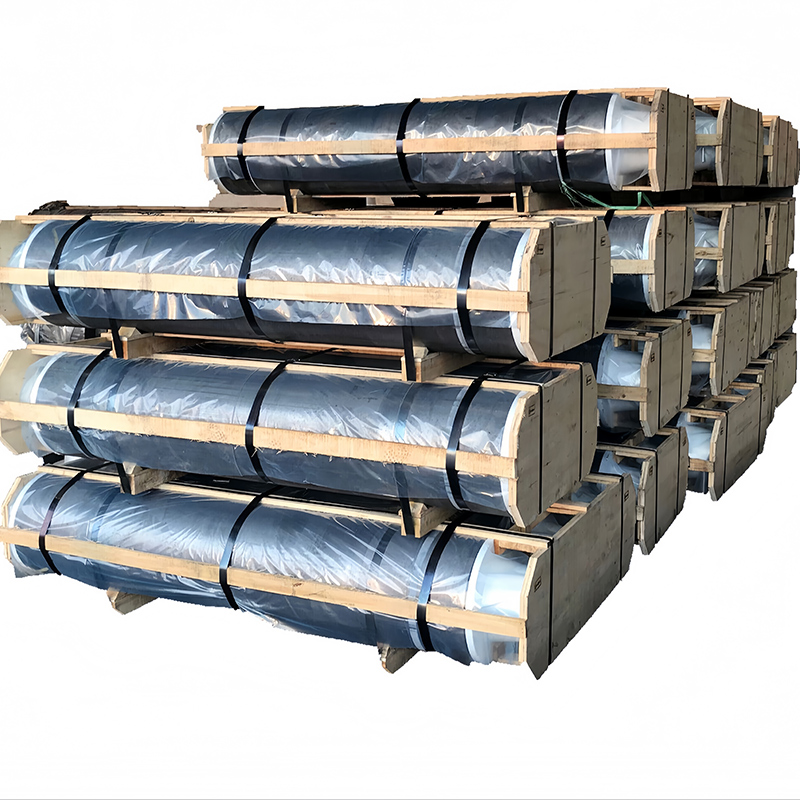

Kakaretso

Ho tloha ho Gran Isostatic Graphite ho li-block tsa li-course-lijo-thollo tse ling le litlhoko tsa graphite le litlhoko tsa boenjiniere. Re fana ka lits'ebeletso tsa mochini tse moetlo tse thehiloeng ho litšoantšo tsa bareki, ka mekhoa e feto-fetohang bakeng sa boholo, bohloeki le letsoalo. Lisebelisoa tsa rona tsa graphing li sebelisoa haholo ho Edm Electrode litsamaiso tsa bobolu, li silafatsa lihlomo tsa 'mala, li netefatsa tsitsipano ea methapo le ts'ebetso ea nako e telele.

Lits'oants'o tsa sebopeho sa setšoantšo le likarolo tsa ka pele li fumaneha ka kopo. CNC ho na le kalafo ea likhopolo tse phahameng. E loketse libaka tsohle tse boima.