Products

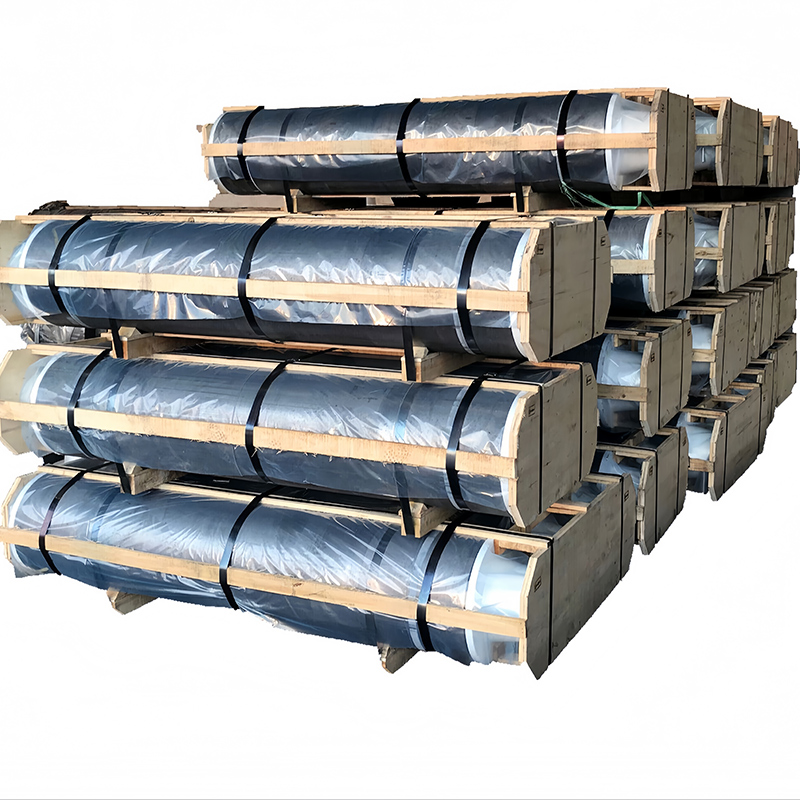

Ultra High Power (UHP) Graphite Electrodes

UHP graphite electrodes are widely used in electric arc furnace steelmaking, offering high conductivity, excellent heat resistance, and mechanical strength, significantly improving smelting efficiency and product quality, making them essential in modern steel production.

Description

marker

Basic Description

The main raw material for manufacturing the body of ultra high power graphite electrodes is imported oil-based needle coke. The production process includes crushing, screening, dosing, mixing, forming, baking, high-pressure impregnation, secondary baking, graphitization, and machining. Nipples are made from imported oil-based needle coke using a process of triple impregnation and quadruple baking.

Technical Specifications of UHP Graphite Electrodes

| Parameter | Unit | Nominal Diameter (mm) | 250~400 | 450~550 | 600~700 |

| Resistivity | μΩ·m | Electrode | 4.8 ~ 5.8 | 4.5 ~ 5.6 | 4.5 ~ 5.4 |

| Nipple | 3.4 ~ 4.0 | 3.4 ~ 3.8 | 3.0 ~ 3.6 | ||

| Bending Strength | MPa | Electrode | ≥ 12.0 | ≥ 12.0 | ≥ 10.0 |

| Nipple | ≥ 22.0 | ≥ 22.0 | ≥ 24.0 | ||

| Elastic Modulus | GPa | Electrode | ≤ 13.0 | ≤ 13.0 | ≤ 13.0 |

| Nipple | ≤ 18.0 | ≤ 18.0 | ≤ 20.0 | ||

| Bulk Density | g/cm³ | Electrode | 1.68 ~ 1.73 | 1.68 ~ 1.72 | 1.68 ~ 1.72 |

| Nipple | 1.78 ~ 1.84 | 1.78 ~ 1.84 | 1.80 ~ 1.86 | ||

| Coefficient of Thermal Expansion (CTE) | 10⁻⁶/°C | Electrode | ≤ 1.2 | ≤ 1.2 | ≤ 1.2 |

| Nipple | ≤ 1.0 | ≤ 1.0 | ≤ 1.0 | ||

| Ash Content | % | ≤ 0.2 | ≤ 0.2 | ≤ 0.2 |

Technical Specifications of UHP Graphite Electrode Nipples

| Nominal Diameter (mm) | Allowable Current (A) | Current Density (A/cm²) |

| 250 | 9000 ~ 14000 | 18 ~ 25 |

| 300 | 15000 ~ 22000 | 20 ~ 30 |

| 350 | 20000 ~ 30000 | 20 ~ 30 |

| 400 | 25000 ~ 40000 | 16 ~ 24 |

| 450 | 32000 ~ 45000 | 19 ~ 27 |

| 500 | 38000 ~ 55000 | 18 ~ 27 |

| 550 | 45000 ~ 65000 | 18 ~ 27 |

| 600 | 52000 ~ 78000 | 18 ~ 27 |

| 650 | 70000 ~ 86000 | 21 ~ 25 |

| 700 | 73000 ~ 96000 | 18 ~ 24 |

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic