Products

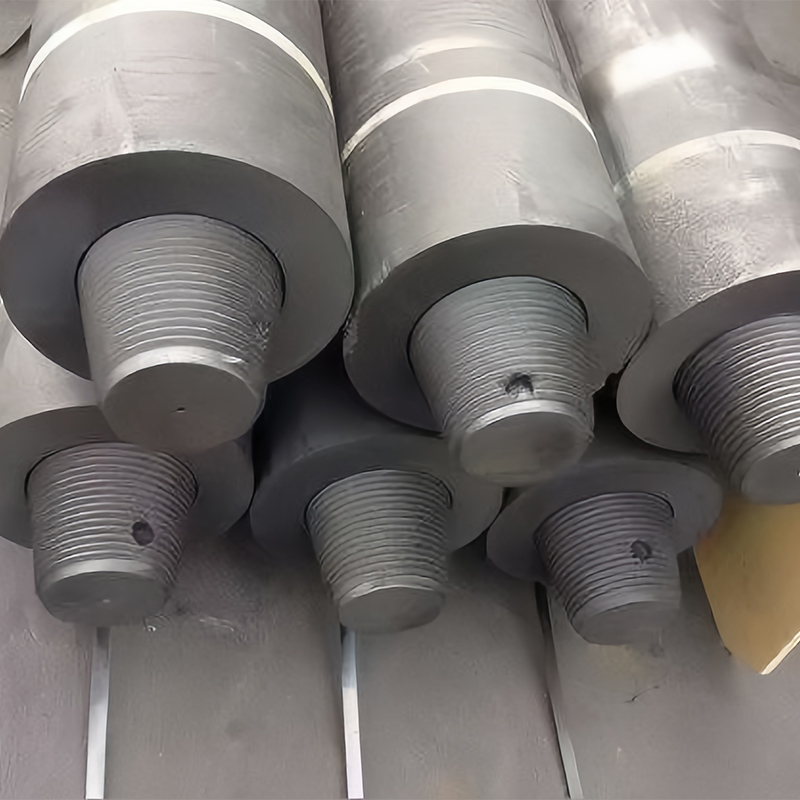

450mm High Power (HP) Graphite Electrode – Optimized for Yellow Phosphorus and Stainless Steel Smelting

The 450mm HP graphite electrode is optimized for yellow phosphorus and stainless steel smelting, delivering superior conductivity, thermal shock resistance, and oxidation durability in high-load operations.

Description

marker

Basic Description

The 450mm High Power (HP) graphite electrode is specifically engineered for high-temperature electric smelting operations, including yellow phosphorus production in submerged arc furnaces (SAFs) and stainless steel refining in electric arc furnaces (EAFs). With a current density range of 15-24 A/cm², this electrode ensures consistent electrical performance and structural integrity under high thermal and mechanical loads.

HP Graphite Electrode Parameters — 450mm

| Item | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 5.2 ~ 6.5 | 3.5 ~ 4.5 |

| Bending Strength | MPa | ≥ 11.0 | ≥ 22.0 |

| Elastic Modulus | GPa | ≤ 12.0 | ≤ 15.0 |

| Bulk Density | g/cm³ | 1.68 ~ 1.73 | 1.78 ~ 1.83 |

| Thermal Expansion CTE | 10⁻⁶/℃ | ≤ 2.0 | ≤ 1.8 |

| Ash Content | % | ≤ 0.2 | ≤ 0.2 |

| Allowable Current | A | — | 25000–40000 |

| Current Density | A/cm² | — | 15–24 |

| Actual Diameter | mm | Max 460 Min 454 | — |

| Actual Length | mm | 1800 ~ 2400 customizable | — |

| Length Tolerance | mm | ±100 | — |

| Short Length | mm | — | — |

Raw Materials & Production Process

The electrode is produced from a raw material blend comprising 60% premium needle coke (sourced from Japan and South Korea) and 5% pitch coke to enhance thermal shock resistance and mechanical strength. A modified coal tar pitch is used as the binder to ensure deep pitch impregnation and optimal carbon bonding.

Forming is performed using a hybrid technique that integrates vibration compaction and isostatic pressing. This advanced process ensures uniform density distribution, reduced internal micro-defects, and improved isotropy.

Graphitization is carried out at peak temperatures approaching 3000°C to enhance crystalline alignment, resulting in lower electrical resistivity and improved thermal conductivity. The electrodes are then subjected to a secondary impregnation process to minimize porosity and further enhance oxidation resistance.

Application Scope

● Submerged arc furnaces (SAFs) for yellow phosphorus (P₄) smelting

● Electric arc furnaces (EAFs) for stainless steel production

● Medium- to high-load ferroalloy and non-ferrous metal smelting

Operational & Environmental Considerations

● Handling & Transport:Use collision-resistant forklifts; electrodes must be stored in single-layer horizontal configurations to prevent mechanical stress or thread damage.

● Installation:Thread surfaces should be cleaned with dry compressed air before connection. Avoid using metal brushes or abrasive tools.

● Energy Consumption:Approximate manufacturing energy usage is 7,500 kWh per ton.

● Environmental Compliance:Flue gas treatment systems, including desulfurization and dust collection units, are required to meet environmental emission standards.

Performance Summary

The 450mm HP graphite electrode offers superior thermal conductivity, mechanical strength, and oxidation resistance. Its precision manufacturing and high-purity raw materials ensure extended service life, reduced electrode consumption per ton of metal, and reliable performance in energy-intensive electric furnace operations.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic