Products

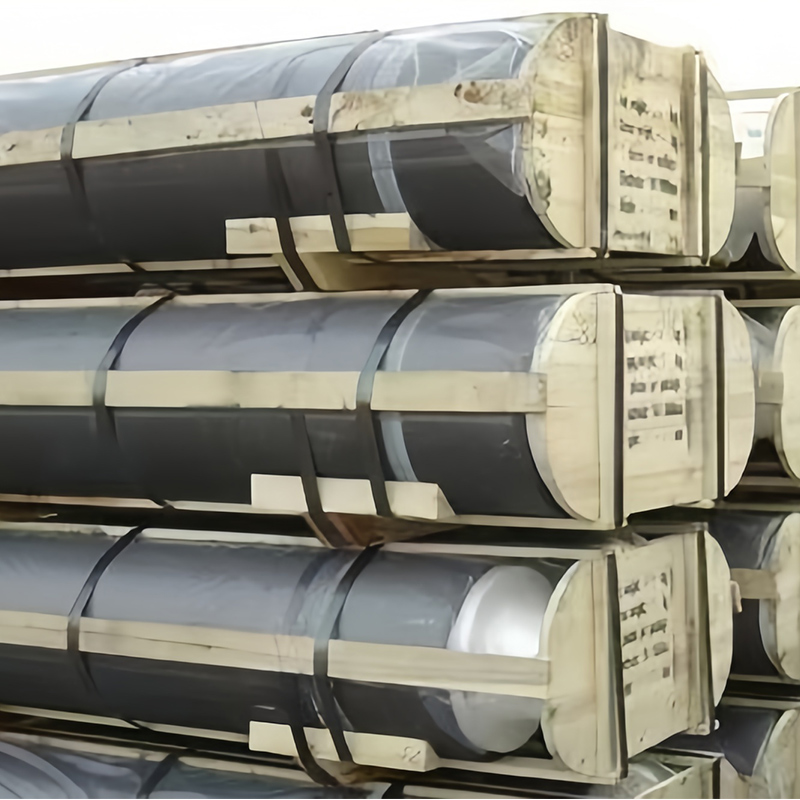

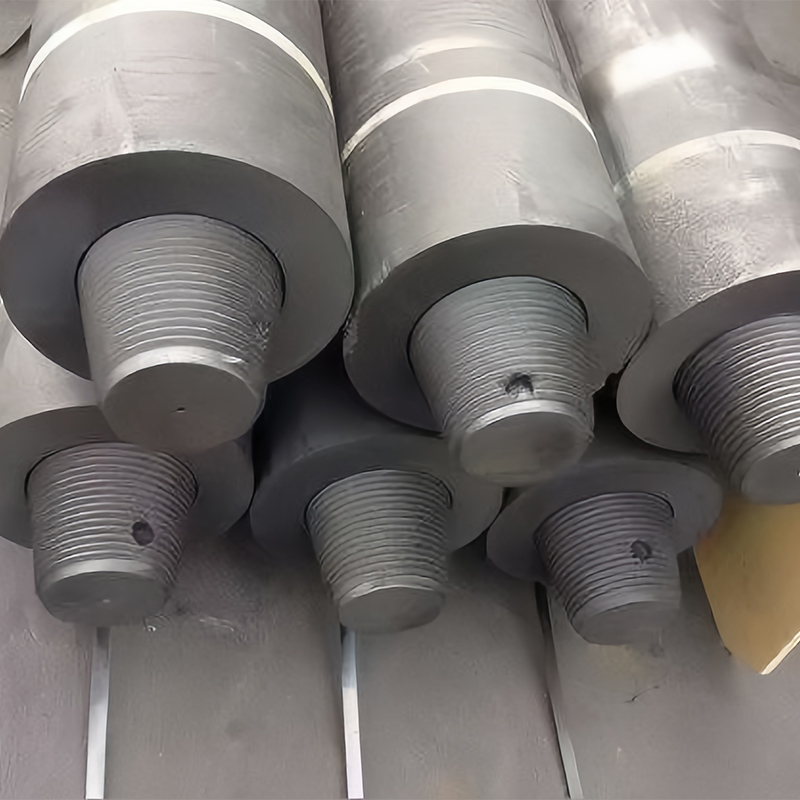

500mm RP Graphite Electrode — Advanced Performance for Large-Scale Electric Arc Furnaces

The 500mm RP graphite electrode is designed for large-capacity EAFs, offering superior conductivity, mechanical strength, and thermal stability. Advanced manufacturing ensures low resistivity and high thermal resistance, reducing electrode consumption and boosting steelmaking efficiency—a cost-effective solution.

Description

marker

Main Description

The 500mm Regular Power (RP) graphite electrode is expertly engineered for large-capacity electric arc furnaces (EAFs), providing exceptional electrical conductivity, mechanical strength, and thermal stability. Designed for standard power applications to ensure an optimal balance between cost-effectiveness and durability, it is ideal for high-volume carbon steel and ferroalloy production.

RP Graphite Electrodes Parameters — 500mm

| Parameter | Unit | Electrode | Nipple |

| Resistivity | μΩ·m | 7.5 ~ 8.5 | 5.8 ~ 6.5 |

| Bending Strength | MPa | ≥ 8.5 | ≥ 16.0 |

| Elastic Modulus | GPa | ≤ 9.3 | ≤ 13.0 |

| Bulk Density | g/cm³ | 1.55 ~ 1.63 | ≥ 1.74 |

| Thermal Expansion Coefficient (CTE) | 10⁻⁶/°C | ≤ 2.4 | ≤ 2.0 |

| Ash Content | % | ≤ 0.3 | ≤ 0.3 |

| Allowable Current | A | — | 25000 ~ 32000 |

| Current Density | A/cm² | — | 13 ~ 16 |

| Actual Diameter | mm | Max: 511 Min: 505 | — |

| Actual Length | mm | 1800 ~ 2400(Customizable) | — |

| Length Tolerance | mm | ±100 | — |

| Short Ruler Length | mm | -275 | — |

Raw Materials & Manufacturing Process:

The 500mm RP electrodes are manufactured using premium-grade petroleum coke blended with a controlled proportion of needle coke to enhance conductivity and mechanical strength. The production process includes:

● High-temperature thermal calcination (up to 1350 °C) to reduce volatile content and improve carbon purity

● Precise mixing with modified coal tar pitch for uniform filler distribution

● High-pressure extrusion and molding to achieve uniform density and minimize structural defects

● Initial baking at 800–900 °C to establish strong carbon bonding

● Vacuum impregnation with pitch followed by secondary baking to reduce porosity and improve oxidation resistance

● High-temperature graphitization at 2800–3000 °C to ensure excellent crystalline structure and minimal electrical resistivity

This process yields electrodes with superior thermal shock resistance, low resistivity, and consistent quality—ideal for continuous, demanding steelmaking operations.

Primary Application Areas:

● Large electric arc furnaces (EAFs) operating under high current and thermal loads

● Ladle furnaces (LFs) for secondary refining and alloy adjustments

● Submerged arc furnaces (SAFs) used in ferroalloy production (e.g., ferrosilicon, ferromanganese)

● Steel plants with annual output exceeding 600,000 tons aiming to reduce electrode consumption and improve cost efficiency

Operational Considerations:

This RP electrode is not suited for Ultra High Power (UHP) furnaces. Strict adherence to current and arc control, alongside routine joint inspection and maintenance, is essential to prevent thermal cracking and maximize electrode life.

Performance Benefits:

● High current capacity for large-scale melt cycles

● Excellent oxidation resistance and thermal shock durability

● Electrode consumption reduction up to 1.0 kg per ton of steel

● Enhanced mechanical strength to minimize cracking and extend service life

● Cost-effective alternative to UHP electrodes in appropriate applications

Conclusion

The 500mm RP graphite electrode is a reliable and efficient solution for large-scale electric arc furnaces. Its advanced structure, low resistivity, and high durability ensure outstanding performance in demanding steelmaking environments. Offering a practical balance between quality and cost, this electrode is ideal for high-volume producers aiming to optimize operational costs without compromising process stability.

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic