Products

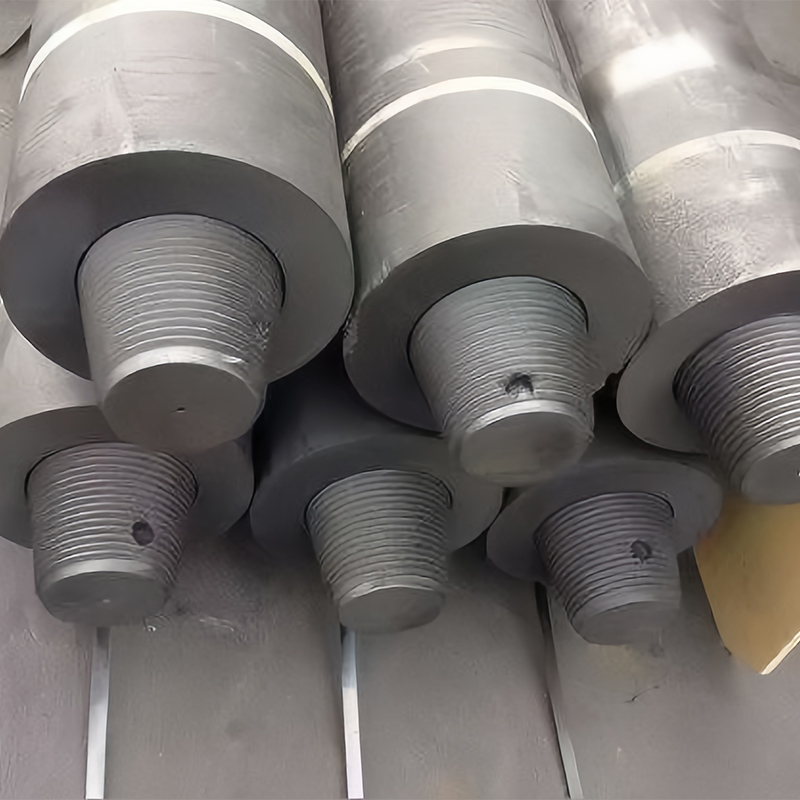

Graphite Electrode Nipples

Graphite electrode nipples are critical components used to connect sections of electrode columns, widely applied in high-temperature industrial equipment such as Electric Arc Furnaces (EAF), Ladle Furnaces (LF), and Submerged Arc Furnaces (SAF).

Description

marker

Basic Description

Precision-Engineered Connectors for High-Temperature Electrode Applications

Graphite electrode nipples are critical components used to join individual electrode columns in high-temperature industrial furnaces, including Electric Arc Furnaces (EAF), Ladle Furnaces (LF), and Submerged Arc Furnaces (SAF). Manufactured from high-density, fine-grain graphite, these nipples are designed to ensure superior electrical conductivity, thermal compatibility, and mechanical integrity. Tapered threads—machined to ISO 8005, DIN 439, or ANSI standards—enable tight, reliable connections between electrode segments.

Key Features

● Exceptional Electrical Conductivity

Optimized structure results in contact resistance ≤ 0.5 μΩ·m², ensuring efficient current transfer with minimal energy loss.

● Thermal Expansion Compatibility

A thermal expansion coefficient (CTE) of 1.5–2.5 × 10⁻⁶/°C, closely matched to electrode bodies, reduces the risk of joint cracking under thermal cycling.

● High Torsional Strength

Engineered to resist torque up to 1000–3000 N·m, providing secure connections during furnace charging and operation.

● Oxidation-Resistant Coatings (Optional)

Aluminum or ceramic coatings are available to enhance service life by 2–3 times, particularly in oxidative or open-arc environments.

Technical Specifications

● Thread Types: 3TPI, 4TPI, 4TPIL (Long Taper Thread)

● Diameter Range: 75 mm to 700 mm

● Electrode Grades: RP (Regular Power), HP (High Power), UHP (Ultra High Power)

● Material: High-density molded or isostatic graphite

● Machining Tolerance: Within ±0.02 mm for critical dimensions

● Standard Compliance: ISO 8005, DIN 439, UHP-5, ANSI/ASME thread profiles

Typical Applications

● EAF Steelmaking

● Ladle Refining Furnaces

● Industrial Silicon and Ferroalloy Production

● Calcium Carbide Furnaces

● Vacuum and Inert-Atmosphere High-Temperature Systems

Graphite nipples are indispensable for modern metallurgical operations requiring durable and electrically efficient electrode assemblies.

Sample Dimensions

| Electrode Diameter | Nipples mm | Nipples Hole Dimensions mm | Thread Pitch | ||||||

| D | d2 | L | I | d1 | H | ||||

| Deviation | ≤ | Deviation | |||||||

| Thread Type | Metric | Inch | (-0.50~0) | (-5~0) | (-1~0) | 10 | (0~0.50) | (0~7) | 8.47 |

| 3TPI | 225 | 9” | 139.70 | 91.22 | 203.20 | 141.22 | 107.60 | ||

| 250 | 10” | 155.57 | 104.20 | 220.00 | 157.09 | 116.00 | |||

| 300 | 12” | 177.16 | 117.39 | 270.90 | 168.73 | 141.50 | |||

| 350 | 14” | 215.90 | 150.00 | 304.80 | 207.47 | 158.40 | |||

| 400 | 16” | 215.90 | 150.00 | 304.80 | 207.47 | 158.40 | |||

| 400 | 16” | 241.30 | 169.80 | 338.70 | 232.87 | 175.30 | |||

| 450 | 18” | 241.30 | 169.80 | 338.70 | 232.87 | 175.30 | |||

| 450 | 18” | 273.05 | 198.70 | 335.60 | 264.62 | 183.80 | |||

| 500 | 20” | 273.05 | 198.70 | 335.60 | 264.62 | 183.80 | |||

| 500 | 20” | 298.45 | 221.30 | 372.60 | 290.02 | 192.20 | |||

| 550 | 22” | 298.45 | 221.30 | 372.60 | 290.02 | 192.20 | |||

| 600 | 24” | 336.55 | 245.73 | 457.30 | 338.07 | 234.60 | |||

| 4TPI | 200 | 8” | 122.24 | 81.48 | 177.80 | 7 | 115.92 | 94.90 | 6.35 |

| 225 | 9” | 139.70 | 98.94 | 177.80 | 133.38 | 94.90 | |||

| 250 | 10” | 152.40 | 109.52 | 190.50 | 146.08 | 101.30 | |||

| 300 | 12” | 177.80 | 129.20 | 215.90 | 171.48 | 114.00 | |||

| 350 | 14” | 203.20 | 148.20 | 254.00 | 196.88 | 133.00 | |||

| 400 | 16” | 222.25 | 158.80 | 304.80 | 215.93 | 158.40 | |||

| 450 | 18” | 241.30 | 177.90 | 304.80 | 234.98 | 158.40 | |||

| 500 | 20” | 269.88 | 198.00 | 355.60 | 263.56 | 183.80 | |||

| 550 | 22” | 298.45 | 226.58 | 355.60 | 292.13 | 183.80 | |||

| 600 | 24” | 317.50 | 245.63 | 355.60 | 311.18 | 183.80 | |||

| 650 | 26” | 355.60 | 266.79 | 457.20 | 349.28 | 234.60 | |||

| 700 | 28” | 374.65 | 285.84 | 457.20 | 368.33 | 234.60 | |||

| 4TPIL | 300 | 12” | 177.80 | 124.34 | 254.00 | 171.48 | 133.00 | ||

| 350 | 14” | 203.20 | 141.27 | 304.80 | 196.88 | 158.40 | |||

| 400 | 16” | 222.25 | 150.00 | 355.60 | 215.93 | 183.80 | |||

| 450 | 18” | 241.30 | 169.42 | 355.60 | 234.98 | 183.80 | |||

| 500 | 20” | 269.88 | 181.08 | 457.20 | 263.56 | 234.60 | |||

| 550 | 22” | 298.45 | 209.65 | 457.20 | 292.13 | 234.60 | |||

| 600 | 24” | 317.50 | 228.70 | 457.20 | 311.18 | 234.60 | |||

| 650 | 26” | 355.60 | 249.86 | 558.80 | 349.28 | 285.40 | |||

| 700 | 28” | 374.65 | 268.91 | 558.80 | 368.33 | 285.40 | |||

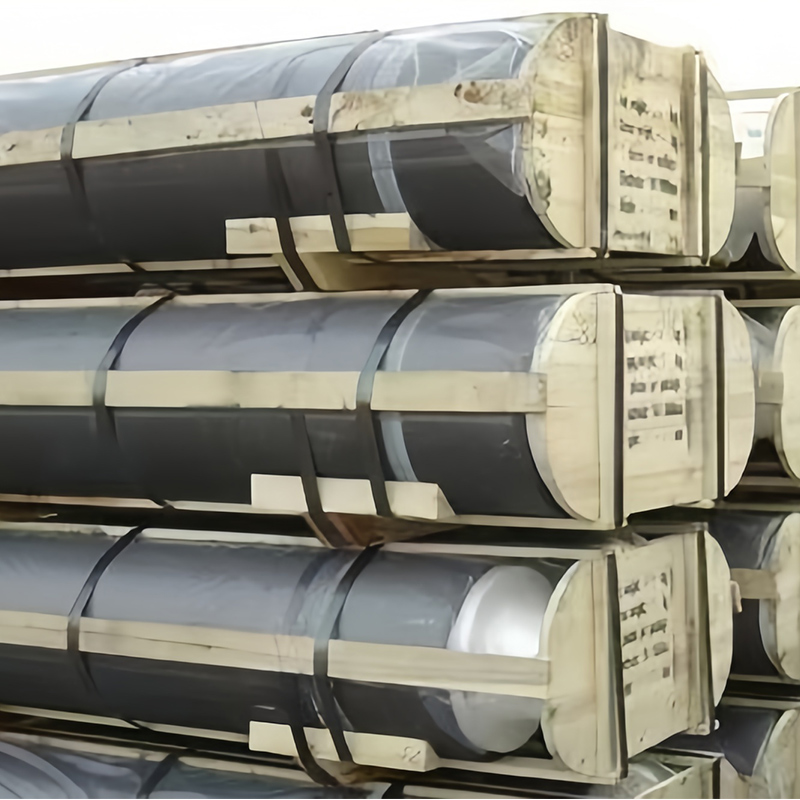

Why Choose Our Graphite Nipples?

● Over 15 years of experience in electrode nipple production

● Advanced CNC machining with stringent dimensional control

● Full traceability of raw materials and production batches

● Custom threading and anti-oxidation coating services

● Rapid delivery of UHP-grade and large-diameter components

contact us

Related popular products

Please leave us a message

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic