Productus

350mm UHP Graphite Electrode - Premium Ultra High Power solutio ad EAF Steelmaking

In 350mm UHP Graphite Electrode est specimen pro magna-facultatem EAF Steelmaking, enabling ieiunium liquescens de exiguo et DRI cum firmum current et humilis consummatio. Suus 'etiam idoneam ad LAX conflantur et summus temperatus Ferroalloy et non-ferrea metallum Smelting, enhancing productivity et ferro puritatem.

Descriptio

venalicium

Product Overview

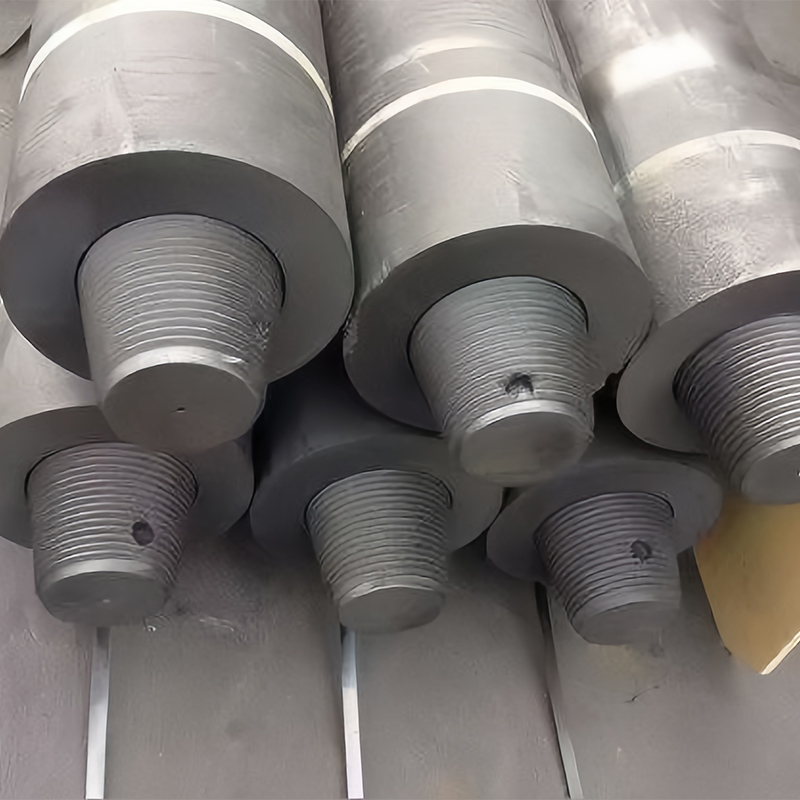

Et 350mm Ultra High Power (UHP) Graphite Electrode est disposito extrema electrica et scelerisque conditionibus in electrica arcus Furnicibus (Equus), Conductore Arcus (Safs). Fabrica a C% premium PETROLEUM, secundum acus Coke et ultra-low sulphure calculus picem, hae electrodes subeunt altus-pressura formatam (per extrusation vel Isostatic urgeat), multi-scaena super MMDCCC ° C.

CRANDIS CNC machining ensurs accurate thread profiles, optimal papilla fit, et humilis contactu resistentia, unde in firmum arcus perficientur, superior conductivity et minimal electrode consummatio.

Technical Specifications - 350mm UHP Electrode

| Parameter | Unitas | Electrode | Papilla |

| Resistentia | ΜΩ · M | 4.8 ~ 5.8 | 3,4 ~ 4.0 |

| Flectens vires | MPA | ≥ 12.0 | ≥ 22.0 |

| Elastica modulus | Gpa | ≤ 13.0 | ≤ 18.0 |

| Mole density | G / CM³ | 1.68 ~ 1.73 | 1.78 ~ 1.84 |

| Thermal expansion coefficient | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Cinis contentus | % | ≤ 0.2 | ≤ 0.2 |

| Licita current | A | - | (XX) ~ (XXX) |

| Current density | A / C² | - | XX ~ XXX |

| Ipsa diameter | mm | Max: CCCLVIII min CCCLII | - |

| Ipsa longitudinem (Fusce) | mm | MDC - MMCD | - |

| Longitudo tolerantia | mm | ± C | - |

| Brevi princeps longitudinem | mm | -275 | - |

Core perficientur commoda

●Ultra-High electrica conductivity

Sustinet celeri arcus initiation et stabilis current fluxus in altus-capaces Furnorum.

●Optimum scelerisque inpulsa resistentia

Minimum scelerisque expansion minimizes fregisset per celeri temperatus mutationes.

●Robustos mechanica vires

Resistat mechanica passiones in operationem, præcipiens et clamping.

●Minimum immunditia contentus

Reducitur cinis, sulphure et volatiles decrescat slag formationem augendae ferro puritatem.

●Praecisione-machined papillis

CNC, machined Sequelae ut stricta electrode, papilla fit, triste iuncturam resistentia et improving conductivity.

Application missionibus

●Prima EAF Steelmaking

Specimen enim liquescens exiguo et DRI in magna-facultatem EAFS, offering ieiunium liquescens cycles et excelsum industria efficientiam.

●Furtum COLUM (LF) secundarium conflans

Maintains temperatus constantia et fines reooxidation durante offering et desulfurization.

●Ferroalloy productio in solat

Manganese Silicon operationes in Silicon continuis summus-Manganese, Ferrochrome et calcium carbide odiosting.

●Summus puritas non-ferrea metallurgy

Usus est in liquescens aluminium, aeris et Titanium Alloys ubi humilis contagione est discrimine.

Manufacturing & Quality Assurance

● Rudis Materials:Premium acus Coke cum sulphuris ≤ 0.03%, humilis cinis et volatiles.

● Formatos & Pistor:Isostatic / extrusionem formatam, sequitur per multi-scaena pistoria ad CM ° C ad dimensional stabilitatem.

● Graphitization:Processionaliter ad ≥ MMDCCC ° C maximum crystallina alignment et conductivity.

● CNC praecisione machining:Electrodes et papillis machined ad stricta tolerances ad lenis juncting.

● Testing Signa:Obsequi cum ASTM C1234, IEC (LX) CCXXXIX, GB / T MMCLXXXIX, et subiectum ad ultrasound, resistentia et vires testis.

Finis-user beneficia

● reducitur Electrode consummatio rate (ECR)

High density et humilis Porosity consequuntur minus gerunt et paucioribus supplementum.

● melius industria efficientiam

Inferior resistivae enables citius liquescens et reducitur industria (KWH / T) usus.

●Superior ferro munditiam

Minimum impudicitiis curare minimal slag et paucioribus non-metallicis inclusions.

●Extended Service Vita

Longius operating circuitus et reducitur downtime per mechanica diuturnitatem.

Conclusio

In 350mm UHP Graphite Electrode offert optimal statera electrica perficientur, mechanica integritas, et scelerisque mollitiam. Engineered ad efficientiam et reliability, reducit operational sumptibus, amplio ferro qualitas, et maximizes fornacem uptime-faciens illud in global chalybaly et mixta productio facilities in global.