Productus

450mm altus potentia (HP) Graphite Electrode - Optimized for Yellow phosphoro et immaculatam ferro Smelting

Et 450mm HP Graphite electrode est optimized for Yellow phosphoro et immaculatam ferro, delivering superior conductivity, scelerisque inpulsa resistentia et oxidatio diuturnitatem in altum onus operationes.

Descriptio

venalicium

Descriptio basic

Et 450mm princeps potentia (HP) Graphite Electrode est specie machinator enim summus temperatus electrica elotis operationes, comprehendo luteum phosphoro productio in submersione arcus in electrica arcus Furnorum (EAFS). Cum a current density range of 15-24 a / CM², hoc electrode ensures consistent electrica perficientur et mechanica onerat in altitudine.

HP Graphite Electrode parametri - 450mm

| Item | Unitas | Electrode | Papilla |

| Resistentia | ΜΩ · M | 5.2 ~ 6.5 | 3,5 ~ 4.5 |

| Flectens vires | MPA | ≥ 11.0 | ≥ 22.0 |

| Elastica modulus | Gpa | ≤ 12.0 | 15.0 ≤ |

| Mole density | G / CM³ | 1.68 ~ 1.73 | 1.78 ~ 1.83 |

| Thermal expansion cte | 10⁻⁶ / ℃ | ≤ 2.0 | ≤ 1.8 |

| Cinis contentus | % | ≤ 0.2 | ≤ 0.2 |

| Licita current | A | - | 25000-40000 |

| Current density | A / C² | - | 15-24 |

| Ipsa diameter | mm | Max CDLX Min CDLIV | - |

| Ipsa longitudo | mm | MDCCC ~ MMCD Customizable | - |

| Longitudo tolerantia | mm | ± C | - |

| Brevi | mm | - | - |

Rudis Materials & Production Processus

In electrode est produci a rudis materia Blerv comprehendente LX% premium acus Coke (Soulced ex Japan et South Korea) et V% picem Coke ad augendae scelerisque impulsa resistentia et mechanica vires. A mutatur carbones tarne picem est usus ut ligans ut profunda picem impregnation et meliorem ipsum vinculum.

Formatam fit per Hybrid ars quod integrates vibrationis compaction and isostatic urgeat. Hoc provectus processus ensures uniformis densitate distribution, reducitur internum micro-defectibus, et improved isotropy.

Graphitization peragitur ad apicem temperaturis appropinquare MMM ° C ad augendae crystallina alignment, unde in inferioribus electrica resistentibus et improved scelerisque conductivity. In electrodes sunt igitur subiecta ad secundarium impregnationem processus ad minimize porosity et porro augendae oxidatio resistentia.

Application scope

● submersus Arcus Furnaces (solatum) for Yellow phosphoro (P₄) Lugubnting

● Electric Arcus Furnaces (EAFS) ad immaculatam ferro productio

● Medio- ad High-onus Ferroalloy et non-ferrea metallum odorem

Operational & environmental considerations

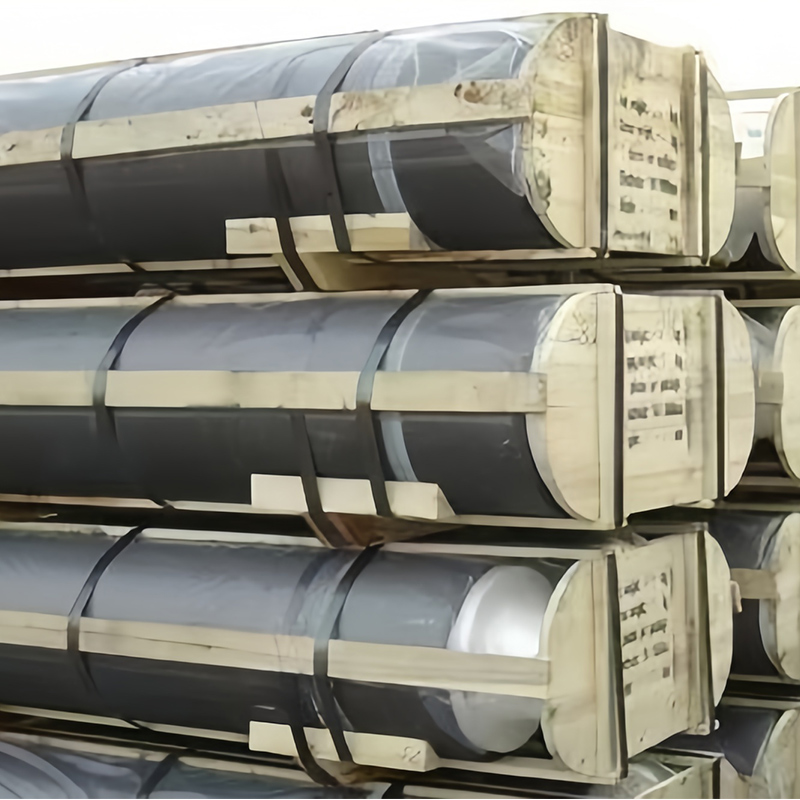

●Handling & onerariam:Uti collisione repugnans forklifts; Electrodes oportet condita in uno-layer horizontali configurationes ne mechanica accentus vel filo dampnum.

●Installation:Thread superficiebus debet purgari cum siccis compressum aeris ante nexum. Vitare per metallum perterget aut abrasive instrumenta.

●Energy consummatio:Propinquus vestibulum industria usus est 7,500 kwh per ton.

●Environmental obsequio:Flue Gas curatio systems, inter Desulfurization et pulvis collectione unitates, quae requiritur ad occursum environmental emissionem signa.

Euismod summary

450mm HP Graphite electrode offert superior scelerisque conductivity mechanica vires et oxidatio resistentia. Eius praecisione vestibulum et summus puritas rudis materiae curare extenditur muneris vitae, reducitur Electrode consummatio per ton of metallum, et reliable perficientur in industria-intensive electrica fornacem operationes.