Productus

600mm altus potentia (HP) Graphite Electrode - Engineered pro Ultra-Gravis-Officium fornacem applications

In 600mm summus potentia graphite electrode est machinator specie pro magna-scale electrica arcum Furnaces (EAF) et demergitur Arcus Furnorum (saf). Eam liberat egregie electrica conductivity, oxidatio resistentia, et scelerisque stabilitatem, faciens ea certa et efficient electionis ad extremum summus temperatus metallurgy.

Descriptio

venalicium

Product Overview

Hoc 600mm HP Graphite Electrode est magna diametro, summus perficientur carbon materia disposito pro ultra-summus potentia metallurgical operationes. Est late in immaculatam ferro conflans, Ferroalloy Smelting, et aliter postulans environments requirere sustinenda princeps current et temperatus stabilitatem.

HP Graphite Electrode parametri - 600mm

| Item | Unitas | Electrode | Papilla |

| Resistentia | ΜΩ · M | 5.2 ~ 6.5 | 3,2 ~ 4,3 |

| Flectens vires | MPA | ≥ 10.0 | ≥ 22.0 |

| Elastica modulus | Gpa | ≤ 12.0 | 15.0 ≤ |

| Mole density | G / CM³ | 1.68 ~ 1.72 | 1.78 ~ 1.83 |

| Thermal expansion cte | 10⁻⁶ / ℃ | ≤ 2.0 | ≤ 1.8 |

| Cinis contentus | % | ≤ 0.2 | ≤ 0.2 |

| Licita current | A | - | 38000-58000 |

| Current density | A / C² | - | 13-21 |

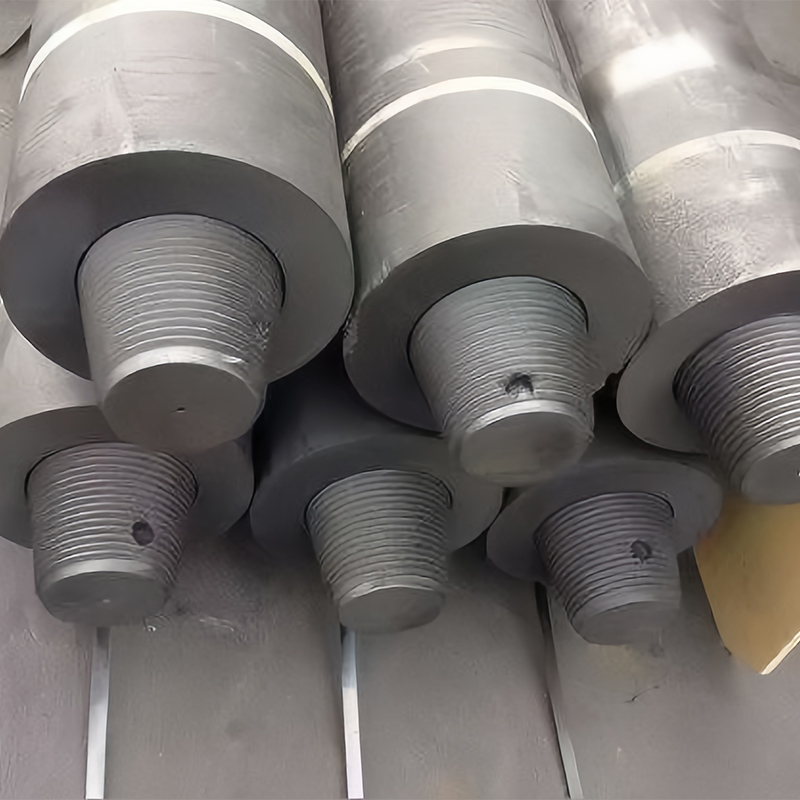

| Ipsa diameter | mm | Max DXIII min DCVII | - |

| Ipsa longitudo | mm | MDCCC * MMDCC Customizable | - |

| Longitudo tolerantia | mm | ± C | - |

| Brevi | mm | - | - |

Rudis Materials & Vestibulum Process

●Materiam compositionem:

①75% Premium PETROLEUM, secundum acus Coke (Sourced ex Iaponia, USA, aut Korea)

②25% calculus-tarne Picem Coke pro optimized sumptus-perficientur statera

③high-softing-punctum mutatio carbones, bare picem ligans et superior ipsum cedat et impregnation mores

●Formatam technology:

Extrusionem et Isostatic urgeat sub alte tonnage ensures densa, isotropic structuram cum minimal interna defectibus.

●Graphitization:

Conducted in LWG (Longitudinal Graphitization fornacem) vel Acheson Furnorum (interiorem diameter ≥2.2m) at ≥3000 ° C ad consequi consistent crystallina alignment et amplificata scelerisque / electrica proprietatibus.

Importning & re-pistoria:

Multipucum pressura impregnation et secundarium pistoria processus dramatically reducere aperta porosity et auget oxidatio resistentia.

Applications

600mm HP Graphite Electrodes sunt communiter in:

● ≥300-ton ultra-summus potentia electrica arcum Furnaces (UHP EAF) ad Steelmaking (Carbon ferro, immaculatam ferro)

● magna-scale demergatur Arcus Furnorum (saf) ad Ferroalloys ut femn, simn, FECTEC

● Non-ferrea metallurgy requiring optimum scelerisque conductivity et æstus stabilitatem

● continua casting et longa-arcus-duratio operationes in Smart Steelmaking environments

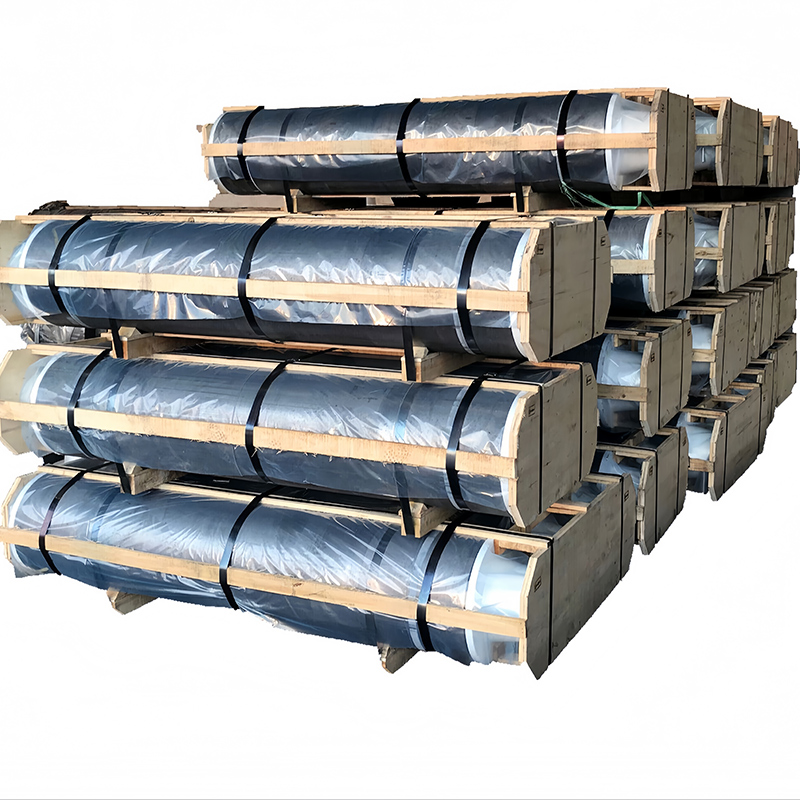

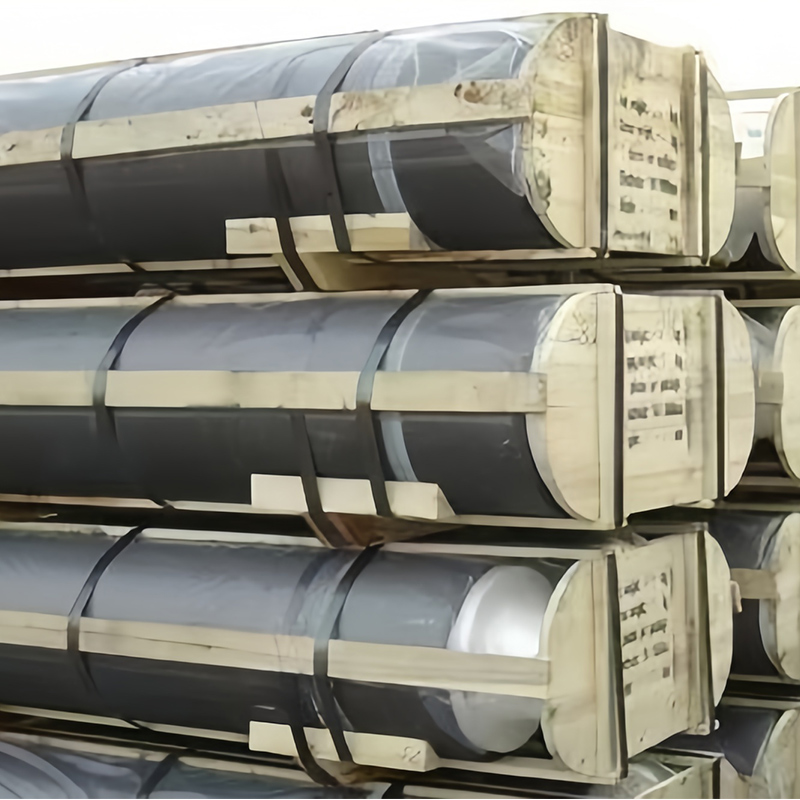

PRAECLUSIO & tractantem instructiones

●Humorem tutela: Store in sicco, bene-ventilari area vitare scelerisque fregisset et oxidatio.

●Storage temperatus: Ponere ad XXV ° C ± V ° C ad meliorem condicionem.

●Packaging: Gravis-officium lignea Crates cum IMPERVIUS interiore liners et inpulsa-absorbing pads.

●Elevatis & tractantem: Tantum utere mollis elevans lora aut dedicated fundas; Nolite sinere metallum vincula et fuscinulas ut contact relatorum vel electrode superficiem.

Clavem perficientur commoda

● Exceptional arcus stabilitatem et anti-fracturam perficientur in extrema calor onerat

● Low Porosity structuram Enhance Oxidatio Resistentia et Service Vita

● humilis electrode consummatio rate (1.7-2.2 kg per ton of ferro sub optimized conditionibus)

● Precision-fit HP papilla ensures secure electrica connectivity cum minimal resistentia

● compatible cum automatic clamping et intelligentes steelmaking systems