Productus

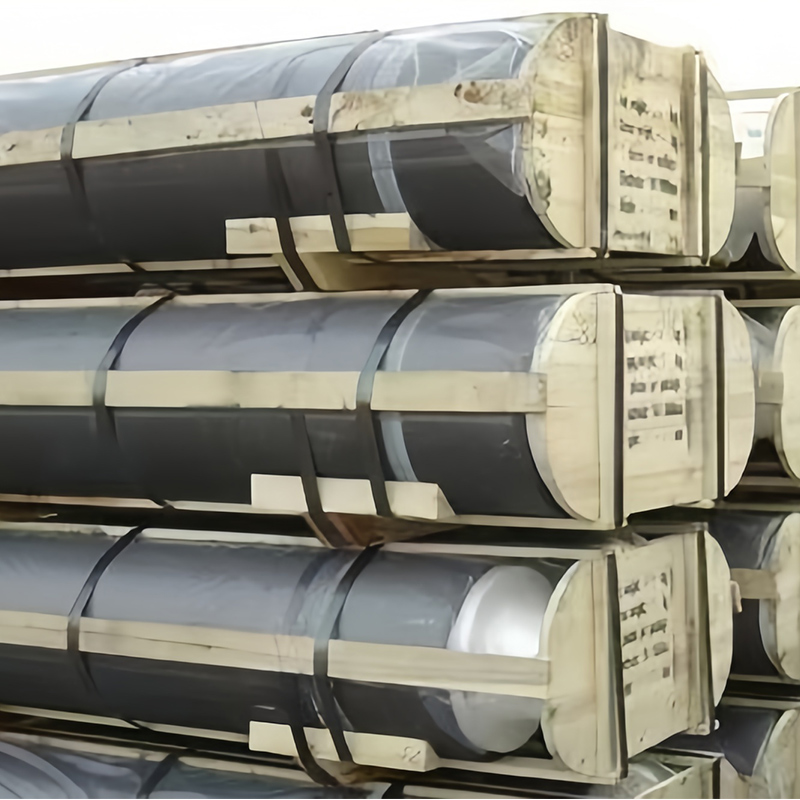

650mm / 700mm UHP Graphite Electrode

Et 650mm et 700mm UHP Graphite Electrodes sunt essentialis pro magna-scale EAF et LF Operations, Enabling efficiens Scrap liquescit et precise ferro conflans. Eorum superior electrica conductivity, scelerisque resistentia, et mechanica vires curare reliable perficientur in extrema industriae condiciones, faciens ea critica ad improving output et ferro qualitas in modern metallurgy.

Descriptio

venalicium

Descriptio basic

Et 650mm et 700mm ultra princeps potentia (UHP) Graphite Electrodes repraesentant summum vexillum in magna-scale steelmaking et non-ferreus conflans, specifically arcus ultra-magno current applications in electrica arcus fornaces (LF). His magna diameter electrodes offerre egregie electrica conductivity, optimum scelerisque inpulsa resistentia et robust mechanica vires sub extrema industriae conditionibus.

Key Technical Specifications:

650mm UHP Electrode

| Parameter | Unitas | Electrode | Papilla |

| Resistentia | ΜΩ · M | 4.5 ~ 5.4 | 3.0 ~ 3,6 |

| Flectens vires | MPA | ≥ 10.0 | ≥ 24.0 |

| Elastica modulus | Gpa | ≤ 13.0 | ≤ 20.0 |

| Mole density | G / CM³ | 1.68 ~ 1.72 | 1.80 ~ 1.86 |

| Thermal expansion coefficient | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Cinis contentus | % | ≤ 0.2 | ≤ 0.2 |

| Licita current | A | - | (LXX) ~ (LXXXVI) |

| Current density | A / C² | - | XXI ~ XXV |

| Ipsa diameter | mm | DCL | - |

| Ipsa longitudinem (Fusce) | mm | MMCC - MMDCC | - |

| Longitudo tolerantia | mm | ± C | - |

| Brevi princeps longitudinem | mm | -300 | - |

700mm UHP Electrode

| Parameter | Unitas | Electrode | Papilla |

| Resistentia | ΜΩ · M | 4.5 ~ 5.4 | 3.0 ~ 3,6 |

| Flectens vires | MPA | ≥ 10.0 | ≥ 24.0 |

| Elastica modulus | Gpa | ≤ 13.0 | ≤ 20.0 |

| Mole density | G / CM³ | 1.68 ~ 1.72 | 1.80 ~ 1.86 |

| Thermal expansion coefficient | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Cinis contentus | % | ≤ 0.2 | ≤ 0.2 |

| Licita current | A | - | (CMII) ~ (XCVI) |

| Current density | A / C² | - | XXIV ~ XXIV |

| Ipsa diameter | mm | DCC | - |

| Ipsa longitudinem (Fusce) | mm | MMCC - MMDCC | - |

| Longitudo tolerantia | mm | ± C | - |

| Brevi princeps longitudinem | mm | - | - |

Processus & qualis manufacturing

Hi UHP Electrodes sunt fabricari per rigorous processus involving summus puritas acus Coke, sequitur per calciam, coronationem, pistoria, summus pressura impregnation, et summus temperatus graphitization (supra MMDCCC ° C). Precision machining de utroque electrodes et papillis ensures stricta dimensional tolerantia, humilis iuncturam resistentiam, et arcus stabilitatem in altus-virtute operationes.

Applicationem missionibus:

●Electric Arcus fornacem (Eaf) Steelmaking

Specimen pro Ultra-High Power Steel liquefacti Using FRUST vel DRI in magna-scale mola. Hae electrodes tractare continua operationem cum princeps arcus temperaturis et ingens electrica onerat.

●Ladem (LF) conflans

Critica in secundarium metallurgy ad temperatus imperium, mixture referendo, et inclusio remotionem-ensuring mundi, summus qualis ferro output.

●Non-ferrea summus temperatus odiosis

Item in aluminium, aeris et nickel liquescens, ubi consistency et puritas essentialis productum qualis et fornacem efficientiam.

Key commoda:

● High electrica conductivity → Enhances Energy Efficens et Arca Stabilitas

● optimum scelerisque inpulsa resistentia → reliable euismod in cyclica scelerisque accentus

● High mechanica fortitudinem → reduces periculo fractio

● Minimum cinis et impura → conservat conflandum puritatem et finem-uber species

● Long Service Vita → Dimislatorium totalis consummatio per ton of ferro

Conclusio

650mm et 700mm UHP Graphite Electrodes sunt necessaria est summus output, industria-intensive metallurgical operationes. Superioris structuris proprietatibus curare firmum perficientur sub extrema onus condiciones, faciens ea specimen arbitrium pro modern ferro effectrix quaerens reliability, industria efficientiam, et operating costs.