Imikhiqizo

I-600mm uhp graphite electrode

I-electrode ye-graphite ye-600mm e-UHP isetshenziswa kabanzi emathafeni e-arc kagesi (EAF) neLadle) kanye neLatele), ilungele ukusebenza okushisa okuphezulu kanye nokulayishwa okuphezulu. Ngokuvuselelwa okungcono kukagesi, ukumelana okushisayo, kanye nokusetshenziswa okuphansi, kulungele ukuncibilika kwesikebhe, ama-dri, nezinsimbi ezingezona izinsimbi, okwenza kube yikhethelo elikhethwayo lezicelo ze-metallurgical ezithuthukisiwe.

Ukufanisa

okokulakatha

Incazelo eyisisekelo

I-600mm ehp (amandla aphezulu e-Ultra) I-Graphite Electrode iyi-premium - ibanga le-premium esetshenziswa kakhulu elisetshenziswa kakhulu emathafeni e-arc kagesi (e-EAF) kanye neLaterles Metal Refessing. Ngokuvuselelwa kukagesi okuhlukile, ukumelana okushisayo, namandla okusebenza, le electrode iqinisekisa ukusebenza kahle ngaphansi kwezimo ezisezingeni eliphakeme kakhulu nezimo zamanje.

Ukucaciswa kwezobuchwepheshe okubalulekile:

| Ipharameter | Umuvo | I-electrode | Ingono |

| Ukumelanakabisa | μ ω | 4.5 ~ 5.4 | 3.0 ~ 3.6 |

| Amandla okugoba | I-MPA | ≥ 10.0 | ≥ 24.0 |

| I-Elastic modulus | Uhlobo | ≤ 13.0 | ≤ 20.0 |

| Ubuningi obuningi | g / cm³ | 1.68 ~ 1.72 | I-1.80 ~ 1.86 |

| Ukunwebeka okwenziwe nge-thermal | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Okuqukethwe kwe-Ash | % | ≤ 0.2 | ≤ 0.2 |

| Kuvunyelwe okwamanje | A | - | I-52000 ~ 78000 |

| Ukuqina kwamanje | A / cm² | - | 18 ~ 27 |

| Ububanzi bangempela | m | I-600 | - |

| Ubude bangempela (ngezifiso) | m | 2200 - 2700 | - |

| Ubude Ukubekezelelana | m | ± 100 | - |

| Ubude bombusi omfishane | m | -300 | - |

Inqubo Yokukhiqiza:

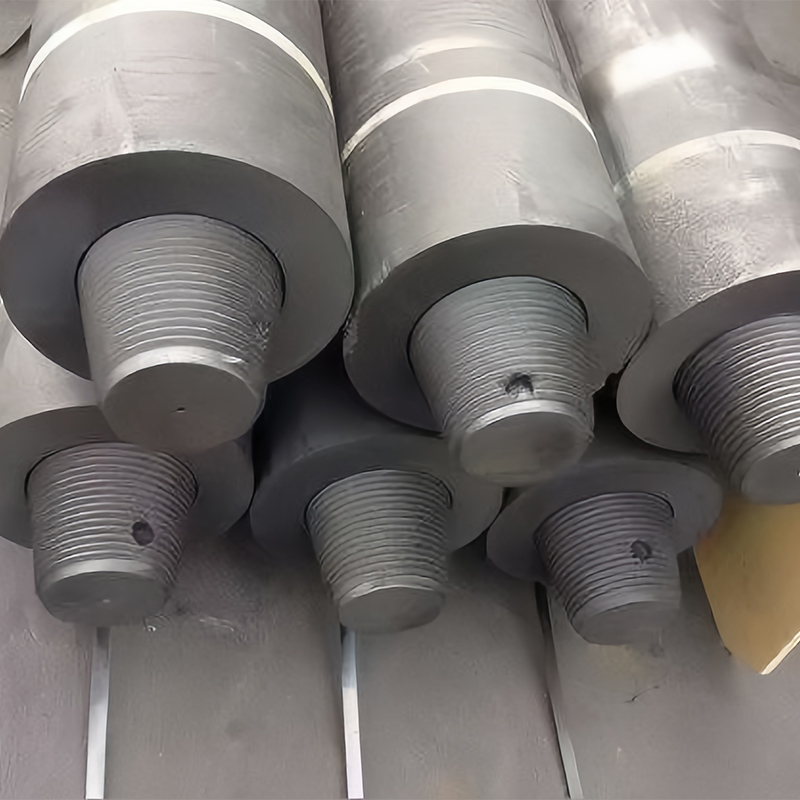

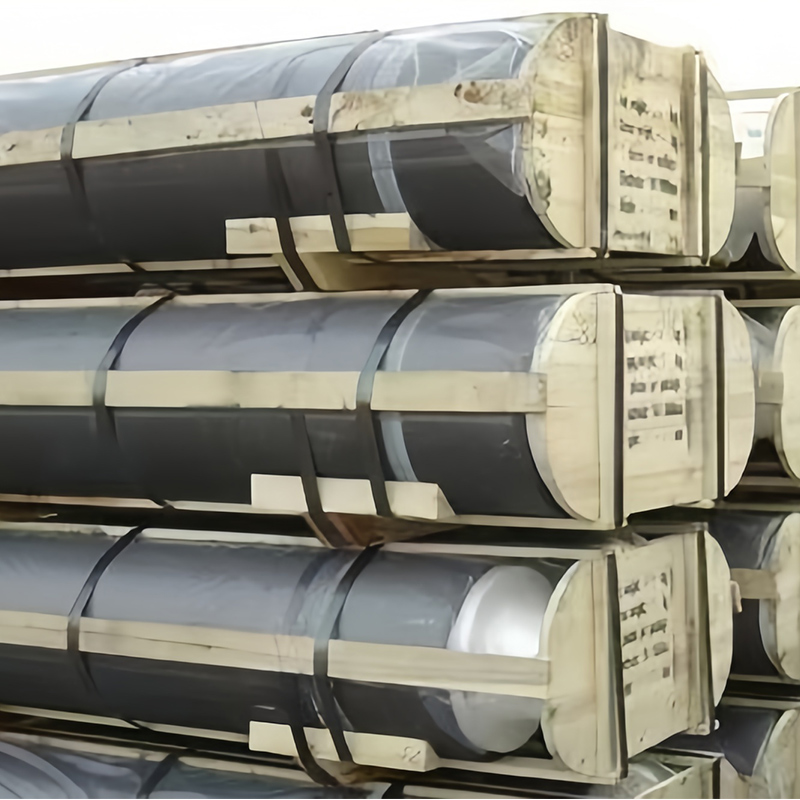

Ama-electrodes we-graphite angama-600mm e-UHP enziwa nge-coke ye-high ebumsulwa, ecutshungulwa nge-calloination, ekwakheni, ukubhaka, ukufakwa kwengcindezi ephezulu, kanye nemidwebo emazingeni okushisa angaphezu kuka-2800 ° C. Ama-electrodes nezihlaseli zengono kufakwe ngopeni ukuqinisekisa imikhawulo eqinile, ukumelana okuphansi, kanye nokuqina okuphezulu ngesikhathi sokusebenza kwe-arc.

Izimo Zokusebenza:

● Uthando lwe-Electric Arc (EAF) Ensimbimaking

Ezitshalweni ezinkulu zensimbi, ama-electrodes angama-600mm e-UHP abalulekile ekunciphiseni isikhafu kanye ne-drime ngokufaka kwamandla okuphezulu. Baqinisekisa imijikelezo esheshayo enxebekile, ukusetshenziswa kwe-elektrode okuphansi, kanye nokusebenza kwamandla okuphezulu.

● I-Ladle Furace (LF) Metallurgy Secondary

Isetshenziselwa ukunxeshezelwa kokushisa nokulungiswa kwe-alloy yokugcina, ukuqinisekisa ukuthi insimbi ehlanzekile, ukwakheka okuqondile, kanye nokulawulwa kwe-metallurment okuthuthukisiwe.

● Ukuncibilika kwensimbi okungeyona eyokuhlanya

Ibuye isetshenziselwe ukuncibilikisa i-aluminium, yethusi, kanye ne-nickel alloys, lapho amazinga aqinile e-arc kanye namazinga aphansi aphansi kubalulekile ukuze uqede.

Izinzuzo ezibalulekile:

● Ukusebenza okuhle kakhulu: Kuqinisekisa ukudluliswa kwamandla okusebenzayo nokulahleka okuncane

● Ukumelana nokushaqeka okushisayo: isikhathi eside sokuphila ekusebenzeni okuphezulu kwe-thermal-cycle

● Amandla aphezulu ahlelekile: kunciphisa ubungozi bokuphuka ngesikhathi sokuphatha nokulayishwa kwe-arc

● I-Low Ash & Ukungcola: kunciphisa ukungcoliswa kwensimbi ebilisiwe

● Izindleko eziphansi ngethani ngalinye

Isiphetho:

I-electrode ye-600mm uhp ye-graphite iyimpahla ebaluleke kakhulu yensimbi yesimanjemanje kanye ne-metallurgy ethuthukile. Ukuhlanganisa izinto ze-carbon-of-art carbon, ubunjiniyela bokunemba, nokuqina okufakazelwe embonini, kuthuthukisa ukusebenza kwethando ngenkathi kunciphisa izindleko zokusebenza. Ilungele abakhiqizi abagxile ekusebenzeni kahle, ukuvumelana, kanye nokukhipha okuphezulu, le electrode ihambisa inani elikhethekile ekufuneni izindawo ezifunwa kwezimboni.