Imikhiqizo

450mm UHP Graphite Electrode Technical Overview

Amandla we-graphite aphezulu we-450mm e-Ultra aphezulu (i-UHP) i-electrode ebaluleke kakhulu esetshenziswa kabanzi esithandweni se-arc se-arc (eaf) ensimbi, ukucwengwa kwe-ladle, kanye ne-metalluurgy engekho. Inika amandla amahle kakhulu kagesi, ukumelana okuxakayo, namandla omshini wokwandisa ukusebenza kwekhwalithi yensimbi nekhwalithi yensimbi.

Ukufanisa

okokulakatha

Incazelo eyisisekelo

Amandla we-graphite aphezulu we-450mm aphezulu (i-UHP) I-Electrode ye-Graphite iyisifo esibucayi esisetshenziswa kakhulu esithandweni se-arc se-arc (eaf) ensimbi nezinye izinqubo zensimbi eziphakeme ze-metallurgical. Kwenziwe kusuka ku-Petrole-grade Petroleum Coke nasenaleneni i-Coke, futhi kusetshenzwe ngokubhaka okuthuthukile, ukuvezwa kwemishini, kanye nokunemba kwemishini, le ngo-electrode inikeza amandla akhethekile kagesi, ukumelana okwenziwe nge-thermal, namandla omshini.

Ukucaciswa kwezobuchwepheshe okubalulekile

| Ipharameter | Umuvo | I-electrode | Ingono |

| Ukumelanakabisa | μ ω | 4.5 ~ 5.6 | 3.4 ~ 3.8 |

| Amandla okugoba | I-MPA | ≥ 12.0 | ≥ 22.0 |

| I-Elastic modulus | Uhlobo | ≤ 13.0 | ≤ 18.0 |

| Ubuningi obuningi | g / cm³ | 1.68 ~ 1.72 | 1.78 ~ 1.84 |

| Ukunwebeka okwenziwe nge-thermal | 10⁻⁶ / ° C | ≤ 1.2 | ≤ 1.0 |

| Okuqukethwe kwe-Ash | % | ≤ 0.2 | ≤ 0.2 |

| Kuvunyelwe okwamanje | A | - | 32000 ~ 45000 |

| Ukuqina kwamanje | A / cm² | - | 19 ~ 27 |

| Ububanzi bangempela | m | UMax: 460 min: 454 | - |

| Ubude bangempela (ngezifiso) | m | Ngo-1800 - 2400 | - |

| Ubude Ukubekezelelana | m | ± 100 | - |

| Ubude bombusi omfishane | m | -275 | - |

Inqubo Yokukhiqiza

●Ama-Raw material:I-Low-Sulfur Petroleum Inaliti Coke (<0.03%) ukuqinisekisa ubumsulwa obuphezulu nokuvuselelwa.

●Kwakha:Ukucindezela okuzayo ngobuningi bomfaniswano nobuqotho bezinhlekelele.

●Ukubhaka:Ukubhaka kwesigaba esiningi kuze kufike ku ~ 900 ° C ukuthuthukisa amandla nobudlelwano.

●Ukuhlunga:Ukwelashwa ngenhla kwe-2800 ° C ukukhiqiza i-graphite ephezulu esezingeni eliphakeme ngokuqina okuphakeme nokuqina okushisayo.

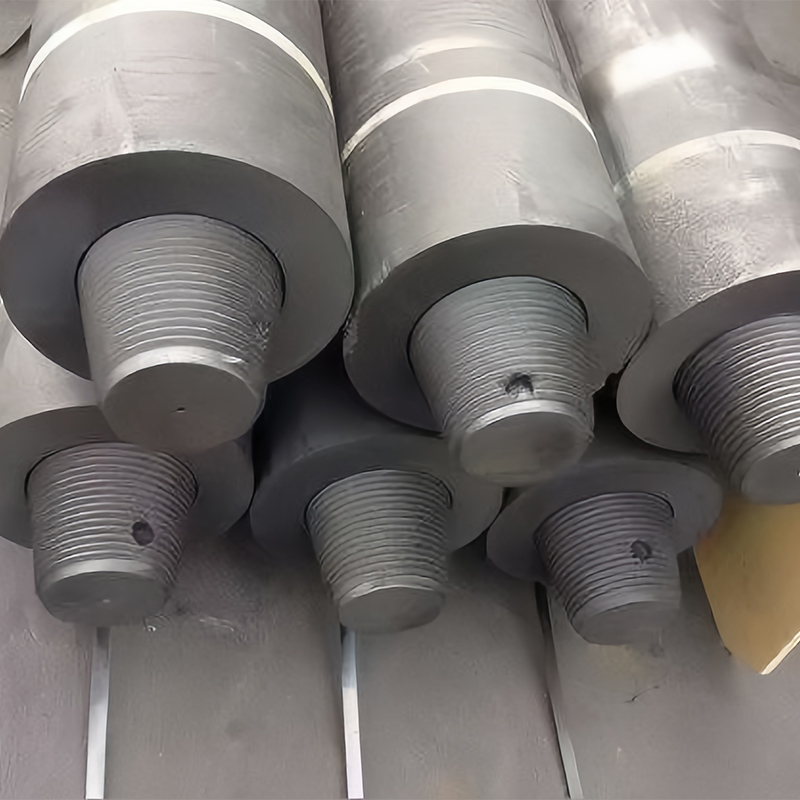

●Imishini:I-PRIVION CNC MachingApling of Threads and Dirensions iqinisekisa ukuxhumeka okuphephile, okuvunyelwe okuphansi.

Izinja

●Ugesi we-arc kagesi (EAF):Ama-electrodes ayisisekelo wokuncibilika kwe-scrap kanye ne-iron eqondile (DRI), ukuhlinzeka nge-arcs ezinzile nokudluliswa kwamandla okusebenzayo.

●I-Ladle Furace (LF) kanye ne-Argon Opygen Decalrubulisization (AOD) RECACES:Ama-electrodes wokucolisiswa okwesibili nokulawulwa kokushisa okuqondile.

●I-Non-Ferrous Metallurgy:Ukuncibilika nokucolisiswa yi-Copper, i-aluminium, nickel, kanye nama-alloy akhethekile adinga ubumsulwa obuphezulu.

●Imboni yamakhemikhali:Isetshenziswa kuma-reactors okushisa aphezulu nasekukhiqizweni kwe-silicon, calcium carbide, namanye amakhemikhali asuselwa kwikhabhoni.

Izinzuzo

●Ukusebenza Kagesi Okuphezulu:Inciphisa ukulahleka kwamandla futhi kunciphise ukusetshenziswa kwamandla.

●Ukumelana okuhle kakhulu okushisayo okushisayo:Kuvimbela ukuqhekeka, kunweba impilo yenkonzo ye-electrode.

●Izakhiwo ezi-robust mechanical:Amandla aqalayo aphezulu kanye ne-elastic modulus amelane nokuxineka kokusebenza.

●Okuqukethwe okungekho emthethweni:Kuthuthukisa ikhwalithi yensimbi ngokunciphisa ukungcoliswa.

●Izingono ezinemishini ye-CNC ngokuqondile:Iqinisekisa ukuxhumeka kukagesi okuqinile, okuvinjezelwe okuphansi nokusebenza kwama-arc ezinzile.

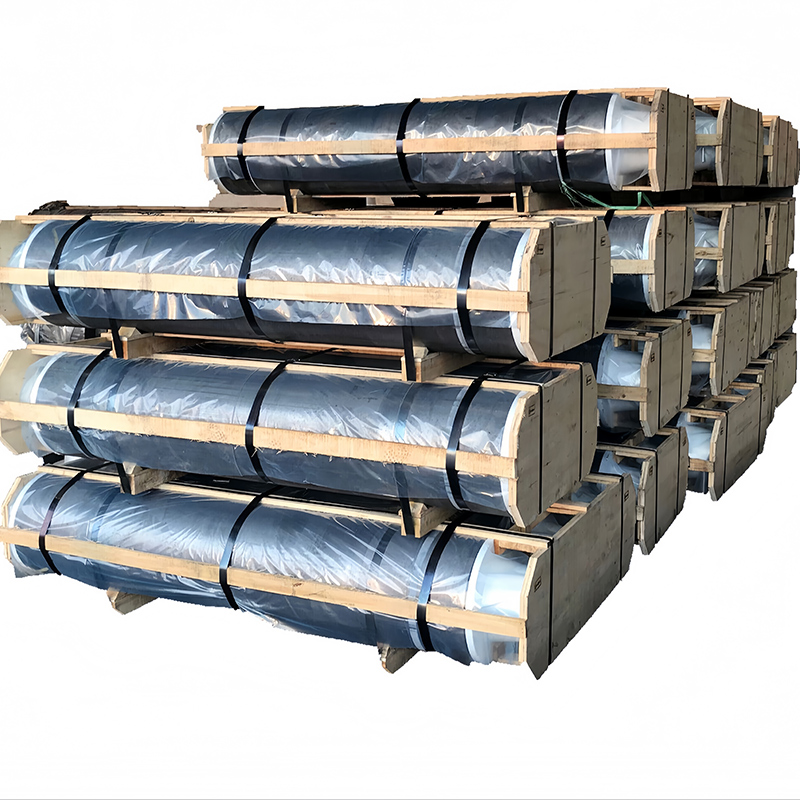

Ukugcina

I-electrode ye-450mm uhp ye-graphite kanye nezingono zayo ezisetshenziswe kahle ngokunembile zivumelana namazinga aphezulu kakhulu okusebenza ngogesi, okushisayo, kanye nemishini. Lokhu kwenza kube yingxenye ebaluleke kakhulu ekusebenzeni okusebenzayo nokuzinzileko kwezinqubo zesimanje ezenziwe ngensimbi kanye ne-metallurgical.