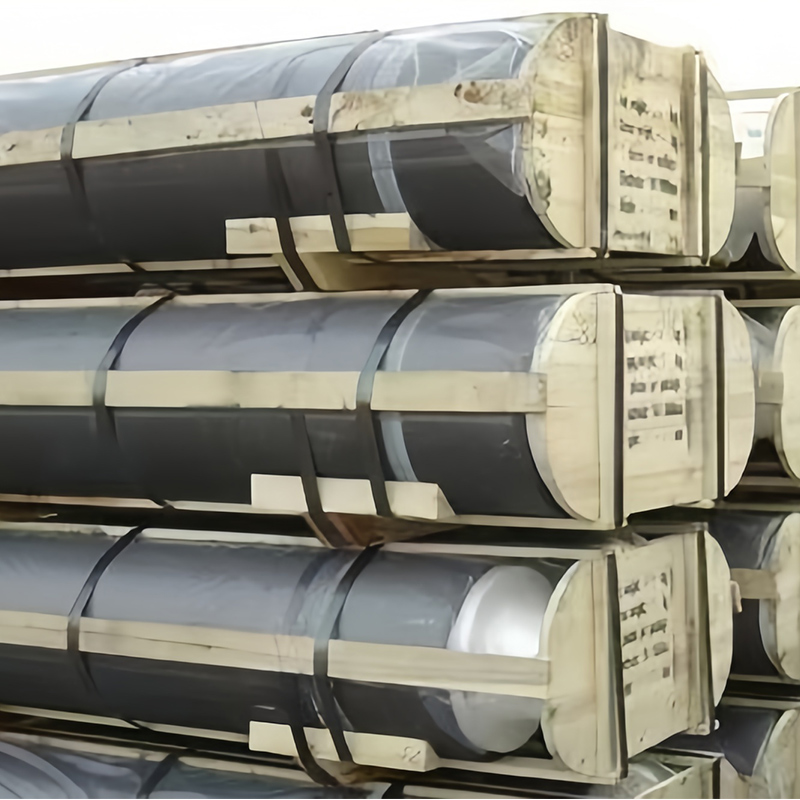

Imikhiqizo

Ama-graphite electrode izingono

Izingono ze-electrode ze-Graphite ziyizakhi ezibucayi ezisetshenziselwa ukuxhuma izingxenye zama-electrode amakholomu, asetshenziswe kabanzi kumishini yezimboni eziphakeme ezifana nezindawo zomlilo kagesi (EAF), kanye nezintokazi ze-Arc (ze-SAF).

Ukufanisa

okokulakatha

Incazelo eyisisekelo

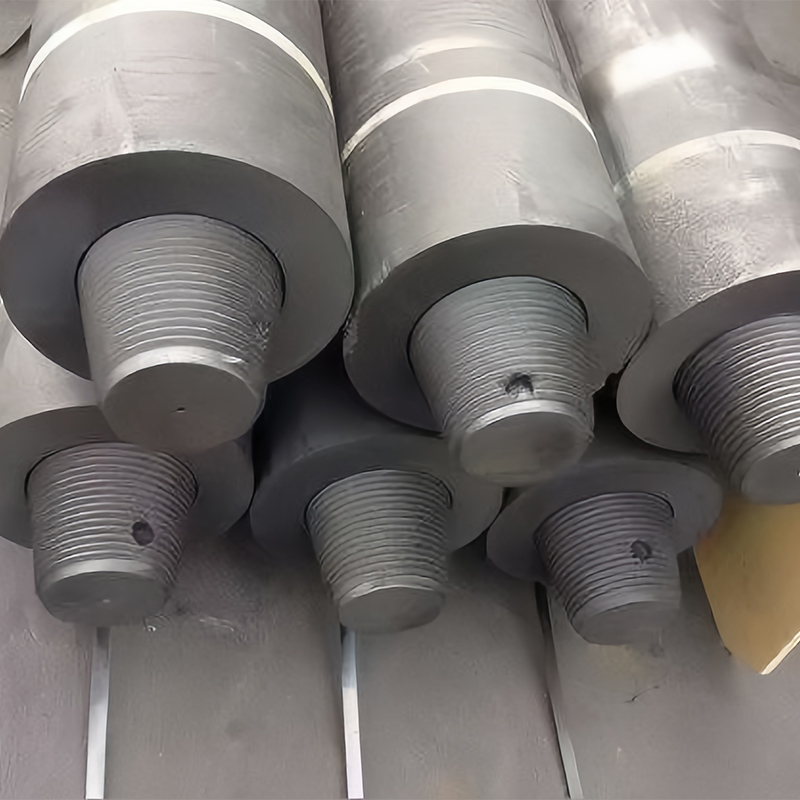

Izixhumi ezinobunjiniyela-zobunjiniyela bezicelo eziphezulu ze-Electrode Electrode

Izingono ze-electrode ze-graphite ziyizakhi ezibucayi ezisetshenziselwa ukujoyina amakholomu we-electrode ezindlini eziphakeme zezimboni, kufaka phakathi izintambo zikagesi ze-arc (eaf), nezintokazi ze-arc (ze-LF). Kwenziwe kusuka ekubuseni okuphezulu, i-graphite enhle yokusanhlamvu, lezi zingono zenzelwe ukuqinisekisa ukuqina kukagesi okuphezulu, ukuhambisana okushisayo nokwethembeka kwemishini. Imicu ye-tapered-macid to iso 8005, DIN 439, noma ama-Ansi Standards-Nika amandla ukuxhumeka okuqinile, ukuxhumana okuthembekile phakathi kwezingxenye ze-electrode.

Izici ezibalulekile

●Ukusebenza okukhethekile kukagesi

Ukwakheka okwenziwe kahle kuphumela ekumelaneni nokuxhumana ≤ 0.5 μωωω ωω 0.5 μω

●Ukufaneleka kokunwetshwa kwe-thermal

I-coefficion ethe xaxa ye-COEFFION (CTE) ye-1.5-2.5 × 10⁻⁶ / ° C, ifaniswe kakhulu nezindikimba ze-electrode, inciphisa ubungozi bokuqhekeka okuhlangene ngaphansi kwebhayisekili eliphansi.

●Amandla aphezulu we-torsional

Unjiniyela ukumelana ne-torque kuze kufike ku-1000-3000 N · m, ukuhlinzeka ukuxhumana okuphephile ngesikhathi sokushaja nokusebenza.

●I-Oxidation-Ukuvimbela Ukuvimbela (Ngokuzithandela)

I-Aluminium noma i-Ceramic Coatings iyatholakala ukuthuthukisa impilo yensizakalo ngezikhathi ezi-2-3, ikakhulukazi ezindaweni ezi-oxidative noma ezivulekile.

Ukucaciswa kobuchwepheshe

●Izinhlobo zentambo: 3TPI, 4TIL, 4TIL (Intambo ende Taper)

●Ububanzi obubanzi: 75 mm kuya ku-700 mm

●Amabanga e-Electrode: I-RP (amandla ejwayelekile), i-HP (amandla aphezulu), i-UHP (amandla aphezulu e-Ultra)

●Into uqobo lwayo: I-graphite ephezulu enobuhlakani noma e-assatic

●Ukubekezelelana kwemishini: Ngaphakathi ± 0.02 mm ubukhulu obukhulu

●Ukuhambisana okujwayelekile: I-ISO 8005, DIN 439, UHP-5, ANSI / ASME Thread Amaphrofayli

Izicelo ezijwayelekile

● Ukwenza insimbi ye-eaf

● Amancanyana acwengile

● I-Silicon Yezimboni kanye neFerroalloy Production

● Izimfanelo zeCalcium Carbide

● Izinhlelo zokushisa okuphezulu ne-inert-armosphere ephezulu

Izingono ze-graphite zibaluleke kakhulu ekusebenzeni kwensimbi yesimanje okudinga amandla ahlala isikhathi eside futhi asebenza ngogesi.

Ubukhulu besampula

| Ububanzi be-elekthrode | Izinongo mm | Izimpungushe umgodi Ubukhulu m | Umttrod Iphimbo | ||||||

| D | d2 | L | I | d1 | H | ||||

| Ukuphambuka | ≤ | Ukuphambuka | |||||||

| Uhlobo lwentambo | Metric | Umuthi ophakathi | (-0.50 ~ 0) | (-5 ~ 0) | (-1 ~ 0) | Okuthenyalwayo | (0 ~ 0.50) | (0 ~ 7) | 8.47 |

| I-3TPI | I-225 | 9 " | 139.70 | 91.22 | 203.20 | 141.22 | I-107.60 | ||

| 25 | 10 " | 155.57 | 104.20 | 220.00 | 157.09 | 116.00 | |||

| 300 | 12 " | 177.1.16 | 117.39 | 270.90 | 168.73 | 141.50 | |||

| 350 | 14 " | 215.90 | I-150.00 | 304.80 | 207.47 | 158.40 | |||

| 400 | 16 " | 215.90 | I-150.00 | 304.80 | 207.47 | 158.40 | |||

| 400 | 16 " | 241.30 | 169.80 | 338.70 | 232.87 | 175.30 | |||

| I-450 | 18 " | 241.30 | 169.80 | 338.70 | 232.87 | 175.30 | |||

| I-450 | 18 " | 273.05 | 198.70 | 335.60 | 264.62 | 183.80 | |||

| 500 | 20 " | 273.05 | 198.70 | 335.60 | 264.62 | 183.80 | |||

| 500 | 20 " | 298.45 | 221.30 | 372.60 | 290.02 | 192.20 | |||

| I-550 | 22 " | 298.45 | 221.30 | 372.60 | 290.02 | 192.20 | |||

| I-600 | 24 " | 336.55 | 245.73 | 457.30 | 338.07 | 234.60 | |||

| I-4TPI | -Mashumi | 8 " | 122.24 | 81.48 | 177.80 | 7 | 115.92 | 94.90 | 6.35 |

| I-225 | 9 " | 139.70 | 98.94 | 177.80 | 133.38 | 94.90 | |||

| 25 | 10 " | 152.40 | 109.52 | 190.50 | 146.08 | 101.30 | |||

| 300 | 12 " | 177.80 | 129.20 | 215.90 | 171.48 | 114.00 | |||

| 350 | 14 " | 203.20 | 148.20 | 254.00 | 196.88 | 133.00 | |||

| 400 | 16 " | 222.25 | 158.80 | 304.80 | 215.93 | 158.40 | |||

| I-450 | 18 " | 241.30 | 177.90 | 304.80 | 234.98 | 158.40 | |||

| 500 | 20 " | 269.88 | 198.00 | 355.60 | 263.56 | 183.80 | |||

| I-550 | 22 " | 298.45 | 226.58 | 355.60 | 292.13 | 183.80 | |||

| I-600 | 24 " | 317.50 | 245.63 | 355.60 | 311.18 | 183.80 | |||

| I-650 | 26 " | 355.60 | 266.79 | 457.20 | 349.28 | 234.60 | |||

| I-700 | 28 " | 374.65 | 285.84 | 457.20 | 368.33 | 234.60 | |||

| I-4TPIL | 300 | 12 " | 177.80 | 124.34 | 254.00 | 171.48 | 133.00 | ||

| 350 | 14 " | 203.20 | 141.27 | 304.80 | 196.88 | 158.40 | |||

| 400 | 16 " | 222.25 | I-150.00 | 355.60 | 215.93 | 183.80 | |||

| I-450 | 18 " | 241.30 | 169.42 | 355.60 | 234.98 | 183.80 | |||

| 500 | 20 " | 269.88 | 181.08 | 457.20 | 263.56 | 234.60 | |||

| I-550 | 22 " | 298.45 | 209.65 | 457.20 | 292.13 | 234.60 | |||

| I-600 | 24 " | 317.50 | 228.70 | 457.20 | 311.18 | 234.60 | |||

| I-650 | 26 " | 355.60 | 249.86 | 558.80 | 349.28 | 285.40 | |||

| I-700 | 28 " | 374.65 | 268.91 | 558.80 | 368.33 | 285.40 | |||

Kungani ukhethe izingono zethu ze-graphite?

● Ngaphezu kweminyaka engu-15 yesipiliyoni ekukhiqizeni ingono ye-electrode

● Imishini ye-CNC ethuthukisiwe ngokulawula okungokoqobo kobukhulu

● Ukulandelela okugcwele kwezinto zokwenziwa kanye nokukhiqizwa kwamabhethri

● Ukuhlwitha ngokwezifiso nezinsizakalo zokulwa ne-oxidation coating

● Ukulethwa okusheshayo kwebanga le-UHP-ibanga nezakhi ezinkulu